A method and system for regulating pressure in a chemical shower room in a biosafety laboratory

A biosafety and shower room technology, which is applied in control/regulation systems, chemistry, fluid pressure control, etc., can solve problems such as reduced opening of pressure regulating valves, failure of biosafety isolation, multiple and complex interference factors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

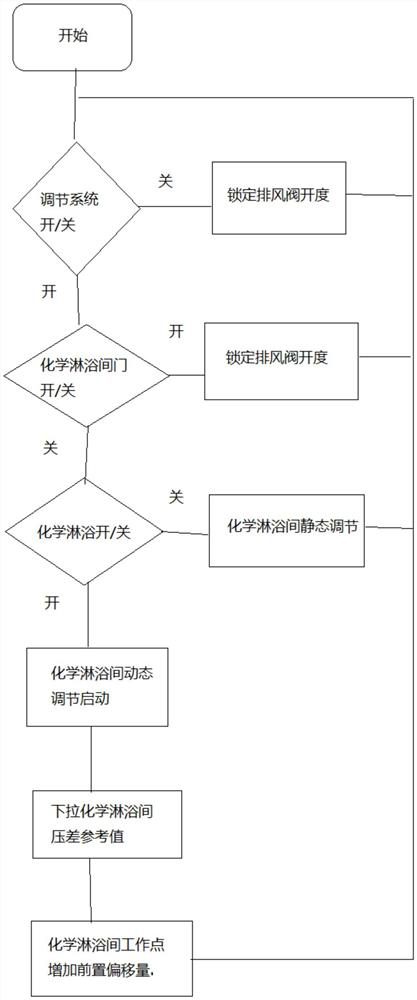

Image

Examples

Embodiment Construction

[0039] In order to better explain the present invention, the main content of the present invention is further clarified below in conjunction with specific examples, but the content of the present invention is not limited to the following examples.

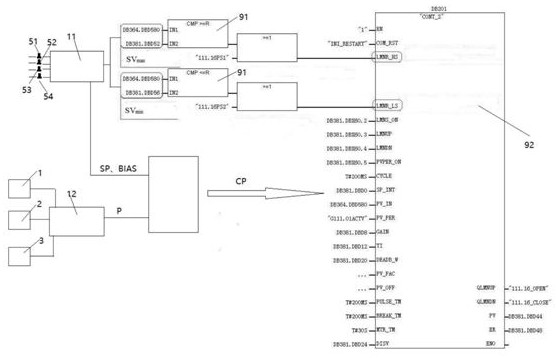

[0040] Such as figure 1 , a biosafety laboratory chemical shower pressure regulating system such as figure 1 Including: biosafety laboratory 21, chemical shower room 22, positive pressure changing room 23, and first changing room 24 arranged side by side in sequence, each room is connected with one end of a branch air supply pipe 42 and an air exhaust branch pipe 43. The other ends of the wind branch pipe 42 and the exhaust branch pipe 43 are collected to the air supply system 50 and the exhaust system 60 respectively, and an exhaust valve 1 is arranged on the exhaust branch pipe connected to the chemical shower 22, and the exhaust valve 1 is The step type electric regulating valve adjusts the pressure in the chemical shower room ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com