Heavy-loading large vacuum heat treatment furnace

A vacuum heat treatment furnace and large-scale technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of insufficient cooling speed, insufficient hardenability, and excessive furnace loading, so as to accelerate the cooling speed and improve the permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

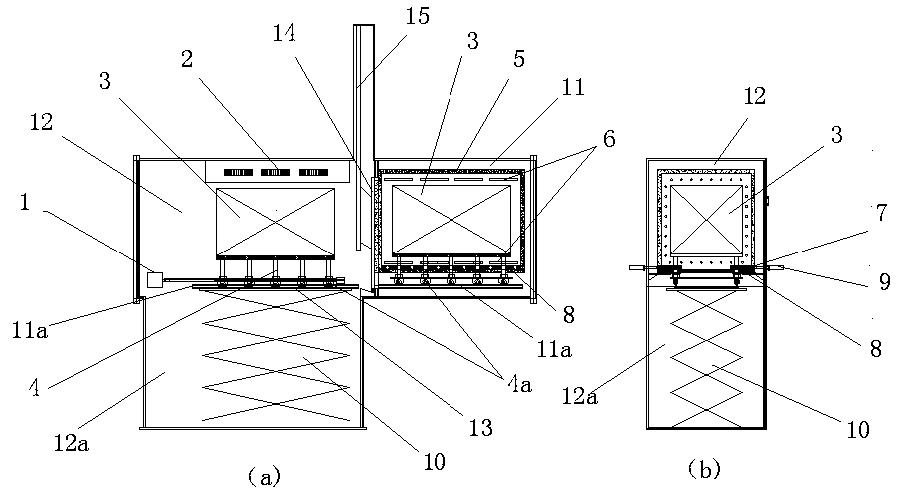

[0018] like figure 1 Shown is a structural diagram of a heavy-loading large-scale vacuum heat treatment furnace of the embodiment, wherein Figure a is a front view, and Figure b is a left view; a structural diagram of a heavy-loading large-scale vacuum heat-treatment furnace is mainly composed of a heating chamber 11 Consists of a cooling chamber 12, the heating chamber is a square structure, the heating chamber is provided with a fixed thermal insulation layer 5, and a plurality of heating sheets 6 are arranged up and down inside the fixed thermal insulation layer, and the bottom thermal insulation layer of the fixed thermal insulation layer 8 is provided with a movable insulation layer 7; the upper part of the cooling chamber is provided with a hot air circulation device 2, the middle is equipped with a rotating pallet 13, the lower part is provided with a quenching pool 12a, and the bottom of the annealing pool is equipped with a lifting mechanism 10, and the lifting mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com