Improved method for preparing Dingyou glue from Sphingomonas sp.

A technology of sphingomonas and diutan gum, which is applied in the field of microbial fermentation, can solve the problems of low shear performance value, poor salt tolerance of diutan gum, difficult extraction of fermentation liquid, etc., and achieve salt resistance and rheology Improve performance, improve salt resistance and rheological properties, improve safety and product whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

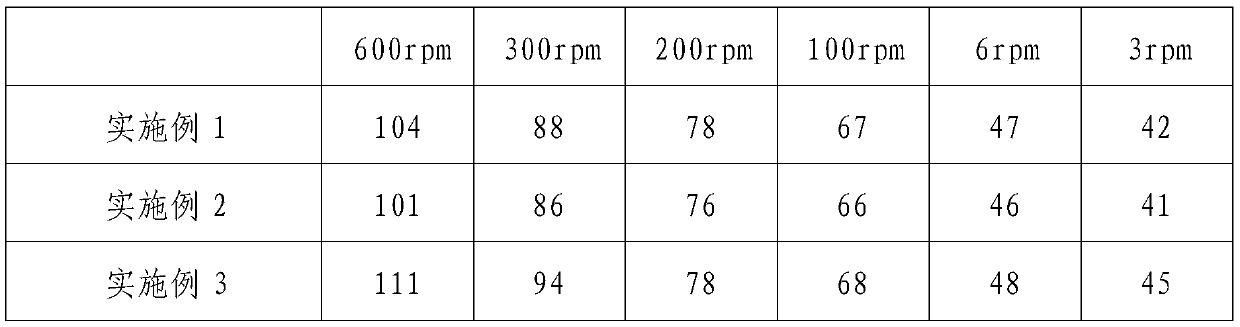

Embodiment 1

[0076] The improved method of producing diyou gum by using Sphingomonas is to inoculate Sphingomonas (SpH value ingomonas sp.) CGMCC No.9531 to the culture after sterilization and contain carbon source and nitrogen source In the liquid, the pH value of the culture liquid is adjusted to carry out ventilation and stirring fermentation, and the fermented liquid after the fermentation is pretreated and extracted to obtain Diyou gum; the following process conditions are also included:

[0077] A. In the culture medium, starch is used as the carbon source, corn steep liquor and ammonium salt are used as the nitrogen source, and the carbon-to-nitrogen ratio in the culture medium is 20:1;

[0078] B. The inoculum size in the aeration and stirring fermentation is 10%; the temperature is 32° C., and the pH value=7.5;

[0079] C. The conditions for pretreatment of the fermented liquid after the fermentation is as follows: adjust the pH value of the fermented liquid to 5.5 and react for 2...

Embodiment 2

[0089] The difference between this embodiment and embodiment 1 is:

[0090] Fermentation and post-extraction also include the following process conditions:

[0091] A. In the culture medium, corn sugar is used as the carbon source, corn gluten powder and nitrate are used as the nitrogen source, and the carbon-nitrogen ratio in the culture medium is 10:1;

[0092] B. The inoculum size in the aeration and stirring fermentation is 8%; the temperature is 30° C., and the pH value=7.0;

[0093] C. The conditions for pretreatment of the fermented broth after the fermentation is as follows: adjust the pH value of the fermented broth to 4.5 and react for 1 hour, and then maintain it at a temperature of 60° C. for 1 hour.

[0094] The fermented broth after the fermentation in the step C is adjusted to pH = 4.5 with 7% hydrochloric acid or 10% chloroacetic acid by mass percentage.

[0095] The added amount of the carbon source is 5% of the mass of the culture solution; the added amount...

Embodiment 3

[0102] The difference between this embodiment and embodiment 1 is:

[0103] Fermentation and post-extraction also include the following process conditions:

[0104] A. In the culture medium, sucrose is used as the carbon source, peanut cake powder, cottonseed powder, and ammonium salt are used as the nitrogen source, and the carbon-nitrogen ratio in the culture medium is 5:1;

[0105] B. The inoculum size in the aeration and stirring fermentation is 5%; the temperature is 28° C., and the pH value=6.5;

[0106] C. The conditions for pretreatment of the fermentation broth after the fermentation is as follows: adjust the pH value of the fermentation broth to 3.5 and react for 0.5 hours, and then maintain the temperature at 50° C. for 0.5 hours.

[0107] The fermented broth after the fermentation in the step C is adjusted to pH=3.5 with 3% hydrochloric acid or 8% chloroacetic acid by mass percent.

[0108] The added amount of the carbon source is 3% of the mass of the culture so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com