Novel kitchen waste anaerobic fermentation treatment device and method

A food waste, anaerobic fermentation technology, applied in the direction of fermentation, sterilization methods, biochemical equipment and methods, etc., can solve high investment costs and processing costs, high operating costs of food kitchen projects, biogas slurry production Complicated water quality and other issues, to achieve the effect of reducing equipment investment, avoiding scum and sand settling problems, and occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

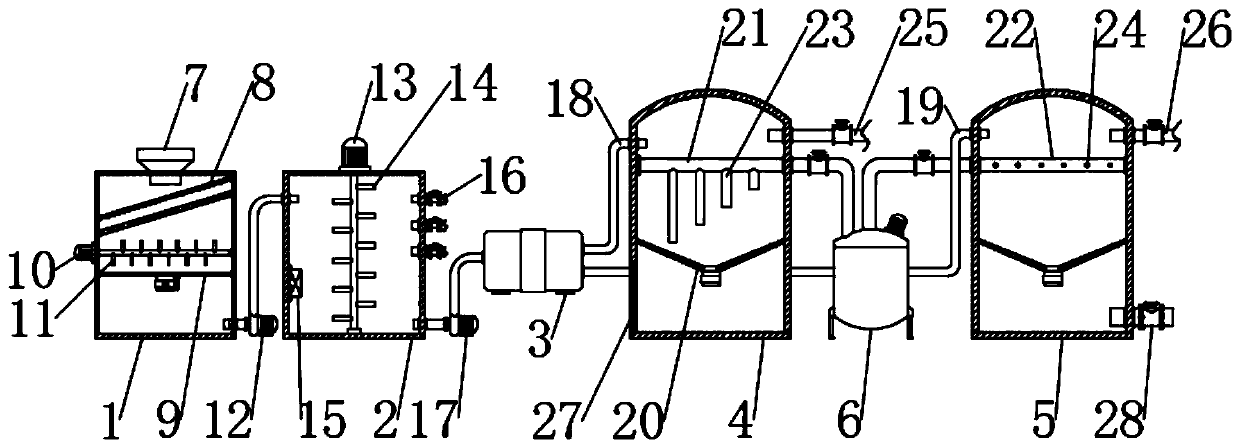

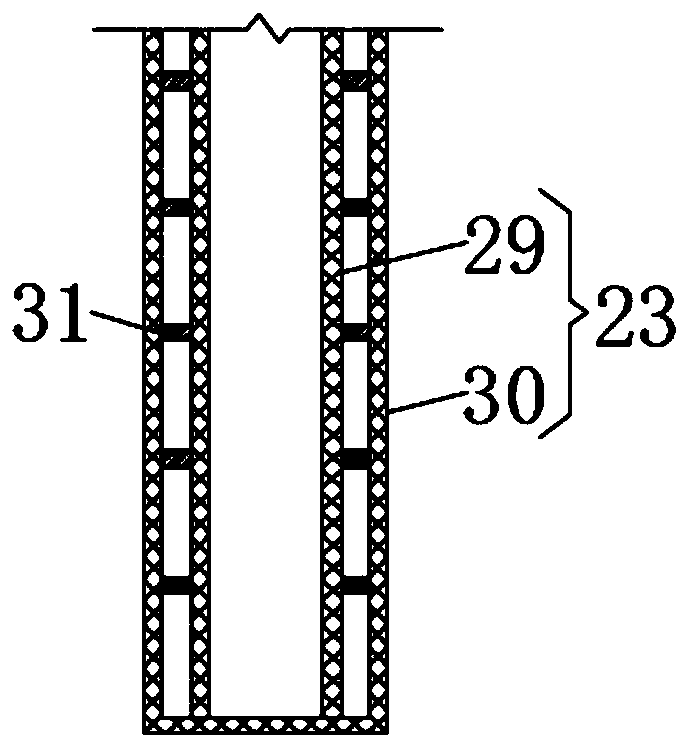

[0029] see Figure 1-2, the present invention provides a technical solution: a novel kitchen waste anaerobic fermentation treatment device, comprising a pulping tank 1, a dehydration tank 2, a plate and frame filter press 3, a dry anaerobic generating tank 4, a wet anaerobic The generation tank 5 and the strain tank 6, the top of the pulping tank 1 is provided with a feed inlet 7, and the upper part of the pulping tank 1 is provided with a sloping filter plate 8, and the middle part of the internal part is provided with a partition 9 horizontally, and the outer side is provided with a The first pump body 12, the liquid inlet of the first pump body 12 extends to the inner bottom of the pulping tank 1 through a pipeline, and the liquid outlet of the first pump body 12 extends to the inner top of the dehydration tank 2 through a pipeline, and the dehydration tank 2 The top of the dehydration tank 2 is fixedly installed with a second motor 13, the inner side of the dehydration tan...

Embodiment 2

[0045] see Figure 1-2 , the present invention provides a technical solution: a novel kitchen waste anaerobic fermentation treatment device, comprising a pulping tank 1, a dehydration tank 2, a plate and frame filter press 3, a dry anaerobic generating tank 4, a wet anaerobic The generation tank 5 and the strain tank 6, the top of the pulping tank 1 is provided with a feed inlet 7, and the upper part of the pulping tank 1 is provided with a sloping filter plate 8, and the middle part of the internal part is provided with a partition 9 horizontally, and the outer side is provided with a The first pump body 12, the liquid inlet of the first pump body 12 extends to the inner bottom of the pulping tank 1 through a pipeline, and the liquid outlet of the first pump body 12 extends to the inner top of the dehydration tank 2 through a pipeline, and the dehydration tank 2 The top of the dehydration tank 2 is fixedly installed with a second motor 13, the inner side of the dehydration ta...

Embodiment 3

[0061] see Figure 1-2 , the present invention provides a technical solution: a novel kitchen waste anaerobic fermentation treatment device, comprising a pulping tank 1, a dehydration tank 2, a plate and frame filter press 3, a dry anaerobic generating tank 4, a wet anaerobic The generation tank 5 and the strain tank 6, the top of the pulping tank 1 is provided with a feed inlet 7, and the upper part of the pulping tank 1 is provided with a sloping filter plate 8, and the middle part of the internal part is provided with a partition 9 horizontally, and the outer side is provided with a The first pump body 12, the liquid inlet of the first pump body 12 extends to the inner bottom of the pulping tank 1 through a pipeline, and the liquid outlet of the first pump body 12 extends to the inner top of the dehydration tank 2 through a pipeline, and the dehydration tank 2 The top of the dehydration tank 2 is fixedly installed with a second motor 13, the inner side of the dehydration ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com