Method for preparing alkylation gasoline

A technology for alkylating gasoline and alkylating oil, which is applied in the petroleum industry and the production of liquid hydrocarbon mixtures. It can solve the problems of irreversible deactivation of catalysts and limit the development of industrialization, achieve good solubilization, realize industrial production, and catalyze The effect of superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

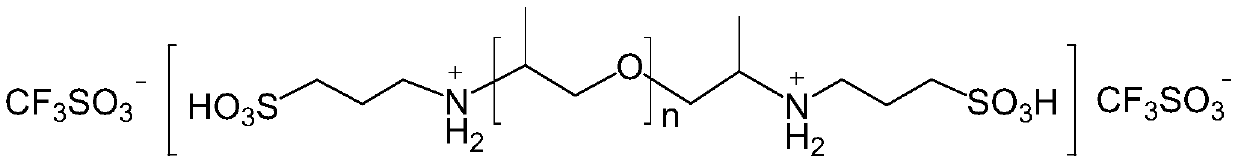

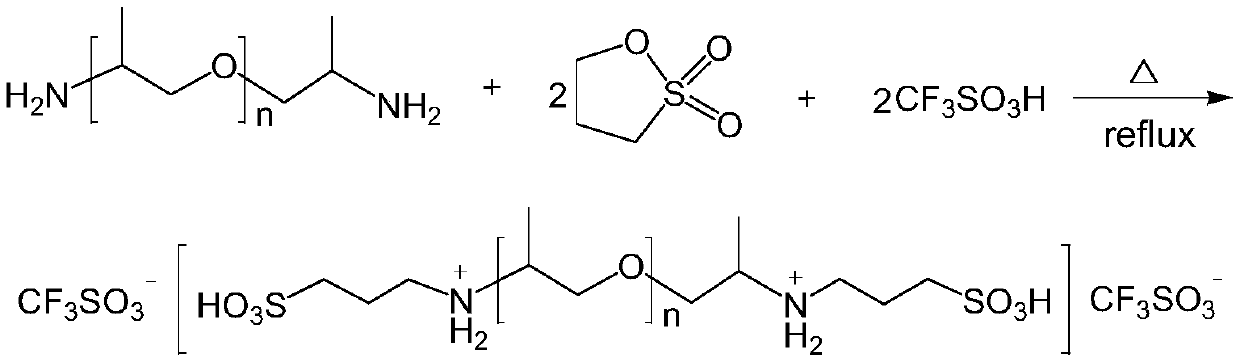

[0018] Example 1: Synthesis of polyetheramine ionic liquid A one-pot method was used. First, 20 g of polyetheramine D-2000 was dissolved in 30 mL of dichloromethane, stirred evenly, and then 2.44 g of 1,3-propanesulfonic acid was added dropwise to it. The lactone was added dropwise, the temperature was raised to 50°C, and the reaction was condensed and refluxed for 2h. After that, 3.01 g of trifluoromethanesulfonic acid was added dropwise thereto, and the reaction was continued at 50° C. for 4 h to stop the reaction. The solvent dichloromethane is removed by rotary evaporation, and the obtained product is vacuum-dried to obtain a polyetheramine ionic liquid catalyst. The synthetic route of polyetheramine ionic liquid is as follows:

[0019]

[0020] (2) Preparation of alkylated gasoline

Embodiment 2

[0021] Example 2: In a stainless steel mechanically stirred reaction kettle, 10 mL of polyetheramine ionic liquid and 3 mL of trifluoromethanesulfonic acid were added, the kettle was sealed, and the air in the kettle was replaced with 4 MPa high-purity nitrogen for 3 times. Then pump 20 mL of a mixed liquid of isobutane and isobutene with an alkane / ene ratio of 10:1, and mechanically stir the reaction at 25 ° C for 20 min. After the reaction is completed, open the kettle to collect the upper alkylated oil phase, and carry out a gas chromatography. Quantitative analysis. The conversion rate of isobutene is 99%, and the selectivity of C8 products in the alkylate oil reaches 87%, of which the proportion of trimethylpentane accounts for 98%.

[0022] (3) Reuse of catalyst

Embodiment 3-15

[0023] Example 3-15: The ionic liquid phase after catalyzing the primary reaction in Example 2 was used as a catalyst, without adding trifluoromethanesulfonic acid. A fresh 20 mL mixture of isobutane and isobutene with an alkane / ene ratio of 10:1 was pumped to carry out the catalytic reaction, and the experimental conditions were the same as those in Example 2. After 13 repeated experiments using the ionic liquid catalyst, the conversion of isobutene is still above 95%, and the selectivity of C8 products in the alkylate is still above 84%.

[0024] (4) Regeneration of catalyst

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com