SnO2-GAC particles and preparation method and application thereof

A technology of sno2-gac and particles, which is applied in chemical instruments and methods, water/sewage treatment equipment, and other chemical processes, can solve the problems of easy falling off, and achieve the effects of uniform heating, low efficiency, and long heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

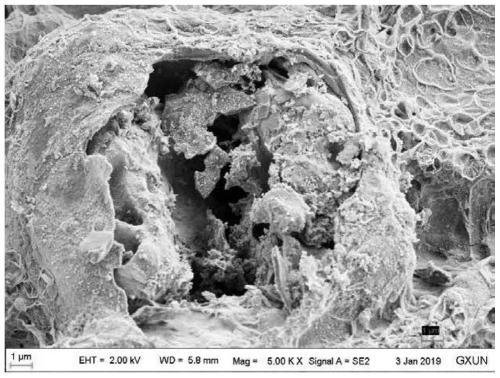

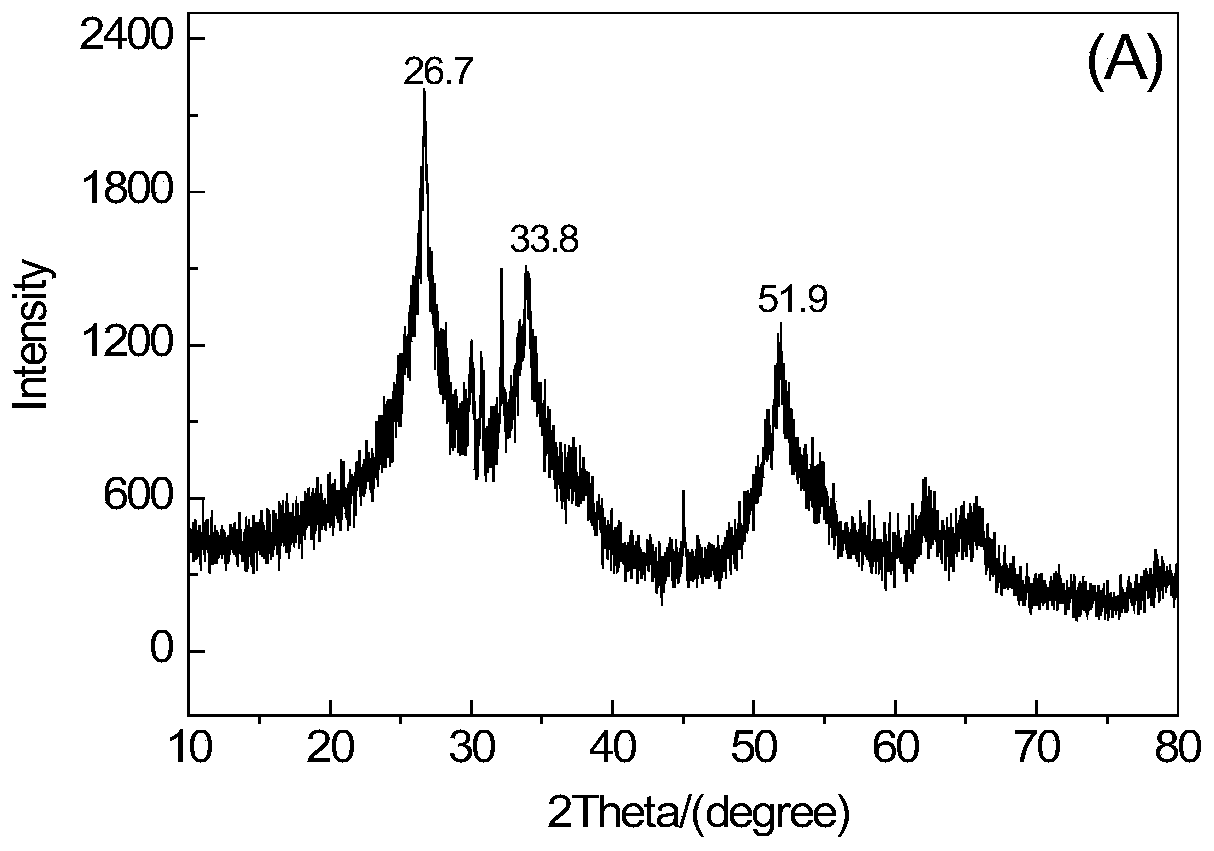

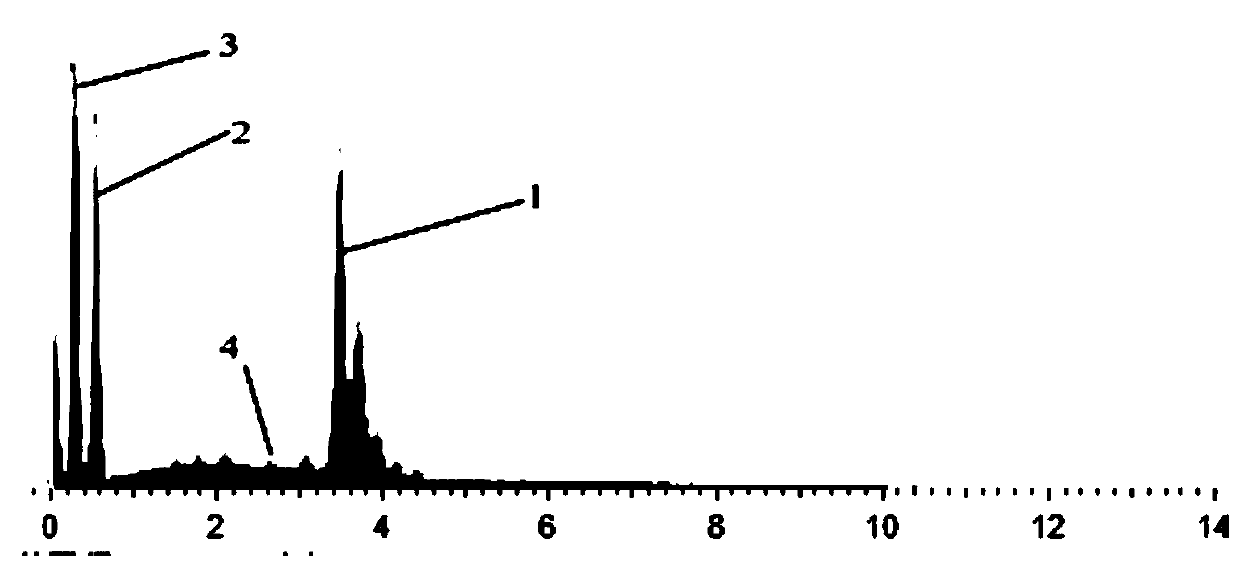

Image

Examples

preparation example Construction

[0045] SnO 2 -The specific steps of the preparation method of the GAC particles include:

[0046] (1) Put the bagasse in a drying oven, take it out after drying for 1.6 hours at a temperature of 103°C, and obtain the pretreated raw material;

[0047] (2) Put the pretreated raw material into a KOH solution with a mass percent concentration of 9wt%, and combine it with ultrasonic soaking for 0.6 hours, filter out the solid matter therein, and dry at a temperature of 103° C. to obtain the primary product;

[0048] (3) Put the initial product in SnCl with a mass concentration of 150g / L 4 ·5H 2 Soak in O solution combined with ultrasound for 0.8 hours, filter out the solids, dry at 103°C, put them in a microwave chemical reactor, treat them under the condition of microwave power of 640W for 13 minutes, and take them out to obtain the crude product;

[0049] (4) after the potassium hydroxide solution cleaning that the crude product is 4.5wt% with a concentration, it is washed to ...

Embodiment 2

[0051] SnO 2 -The specific steps of the preparation method of the GAC particles include:

[0052] (1) Put the astragalus waste residue in a drying oven, take it out after drying at 104° C. for 1.8 hours, and obtain the pretreated raw material;

[0053] (2) Put the pretreated raw material into a KOH solution with a mass percent concentration of 8.5wt%, and combine it with ultrasonic soaking for 0.8 hours, filter out the solids therein, and dry at a temperature of 104° C. to obtain the primary product;

[0054] (3) Put the initial product in SnCl with a mass concentration of 120g / L 4 ·5H 2 Soak in O solution combined with ultrasound for 0.8 hours, filter out the solids, dry at 104°C, put them in a microwave chemical reactor, treat them under the condition of microwave power of 620W for 14 minutes, and take them out to obtain the crude product;

[0055] (4) after the potassium hydroxide solution cleaning that the crude product is 4.7wt% with a concentration, it is washed to ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com