Die-cutting manufacturing device for double-faced adhesive tape

A technology of double-sided tape and double-sided tape, which is applied in the direction of winding strips, sending objects, processing thin materials, etc., which can solve the problems of double-sided tape accumulation and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

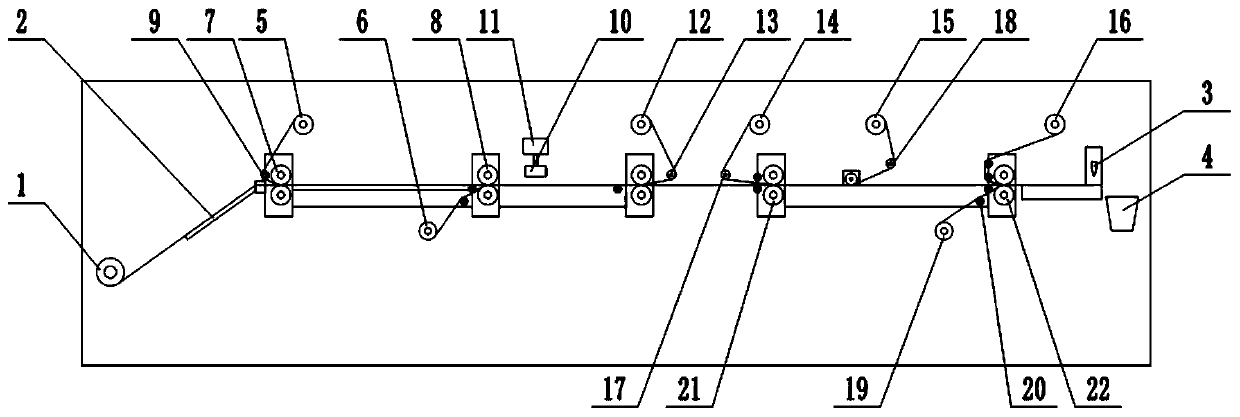

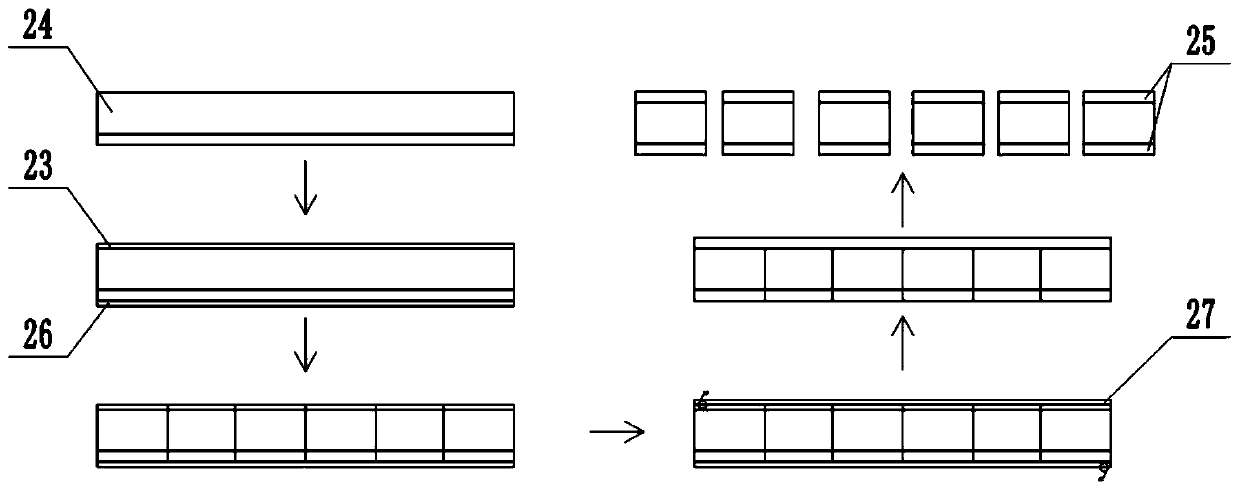

[0026] Embodiment one is basically as attached figure 1 , figure 2 Shown:

[0027] The double-sided tape die-cutting production equipment includes a frame, and the opposite ends of the frame are respectively set as a feed end and a discharge end, and five sets of conveyors for transmitting double-sided adhesive tape are connected in rotation between the feed end and the discharge end. Pair of rollers; the feeding end is provided with a discharge unit for releasing the double-sided adhesive tape, the discharge unit includes a discharge roller 1 that is rotatably connected to the frame, and the frame between the discharge unit and the first set of opposite rollers 7 The material guide plate 2 inclined to the discharge roller 1 is connected by bolts on the top, and a number of parallel guide rollers are connected to the material guide plate 2 in rotation; a die-cutting unit is provided on the discharge end, and the die-cutting unit includes vertical sliding The die cutter 3 th...

Embodiment 2

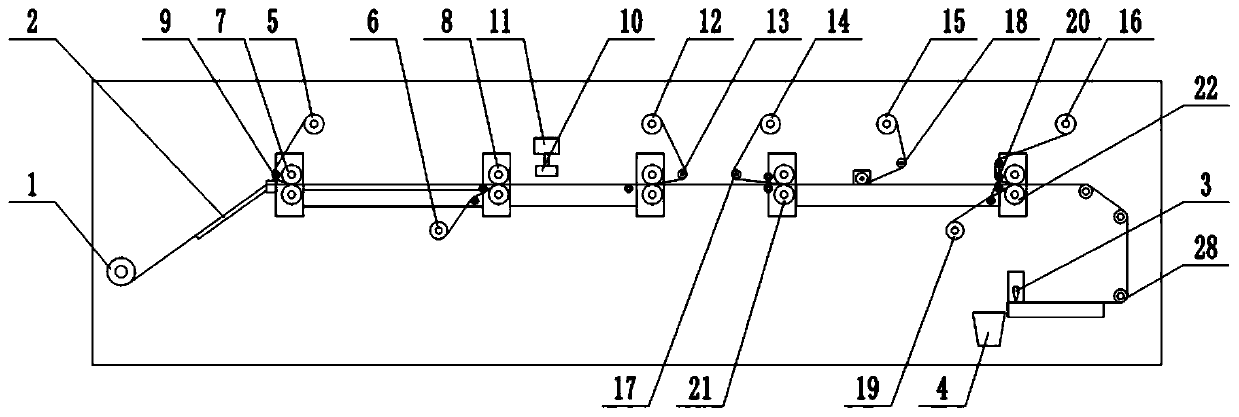

[0036] Embodiment two is basically as attached image 3 Shown:

[0037] This embodiment adds a turning mechanism on the basis of Embodiment 1, specifically: a turning mechanism for changing the front and back sides of the double-sided tape is provided between the double-sided tape reverse side processing mechanism and the die-cutting unit, and the turning mechanism Comprise at least two guide rollers 28 that are rotatably connected on the frame. In the present embodiment, the quantity of guide rollers 28 is three. The double-sided tape is conveyed to the die-cutting unit.

[0038] The pretreated double-sided tape is turned over by the turning mechanism, so that the side with the cut marks faces up, so that it is better to observe whether the cutting is accurate during cutting. Specifically, the transmission of the double-sided adhesive tape is turned by the guide roller 28, so that the double-sided adhesive tape turns over and then enters the die-cutting unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com