Double-sided adhesive tape pasting machine

A technology of double-sided tape and pasting machine, which is applied in the direction of winding strips, sending objects, thin material processing, etc., which can solve the impact of materials and safety, quality education and the improvement of the teaching process, and affect children's hands-on ability and Observation ability and other issues to achieve the effect of ensuring quality and stability, facilitating the die-cutting process, and facilitating the subdivision process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

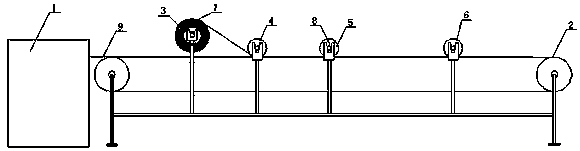

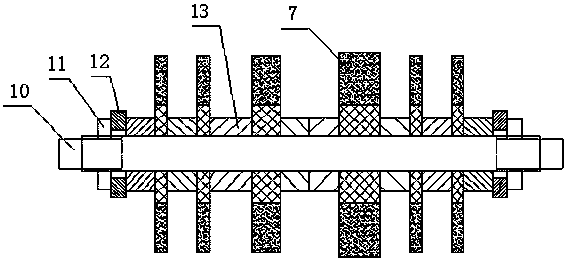

[0019] Attached below figure 1 , figure 2 A further detailed description is given to the double-sided tape pasting machine of the present invention:

[0020] The double-sided adhesive sticking machine of the present invention comprises a conveyor belt 2 in the horizontal direction, a feeder 1 located at the starting end of the conveyor belt 2, a belt feeding mechanism 3 above the conveyor belt 2 and three gravity rollers. The feeder 1 is responsible for continuously sending out the die-cut stickers 9 to the conveyor belt 2 . The three gravity rollers are guide roller 4, pinch roller 5 and positioning roller 6 respectively. The two ends of the roller bodies of the guide roller 4, the pinch roller 5 and the positioning roller 6 are respectively supported above the conveyor belt 2 through the support groove 8 of the trumpet-shaped opening. The rollers 6 are respectively pressed on the conveying surface of the conveyor belt 2 by gravity, and the guide roller 4, the pressure ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com