How to make die-cut indentation bottom plate

A production method and indentation technology, which are applied in the directions of processing and manufacturing, manufacturing auxiliary devices, processing data acquisition/processing, etc., can solve the problems of die-cutting position affecting accuracy and low efficiency, so as to improve significance, automation, and The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

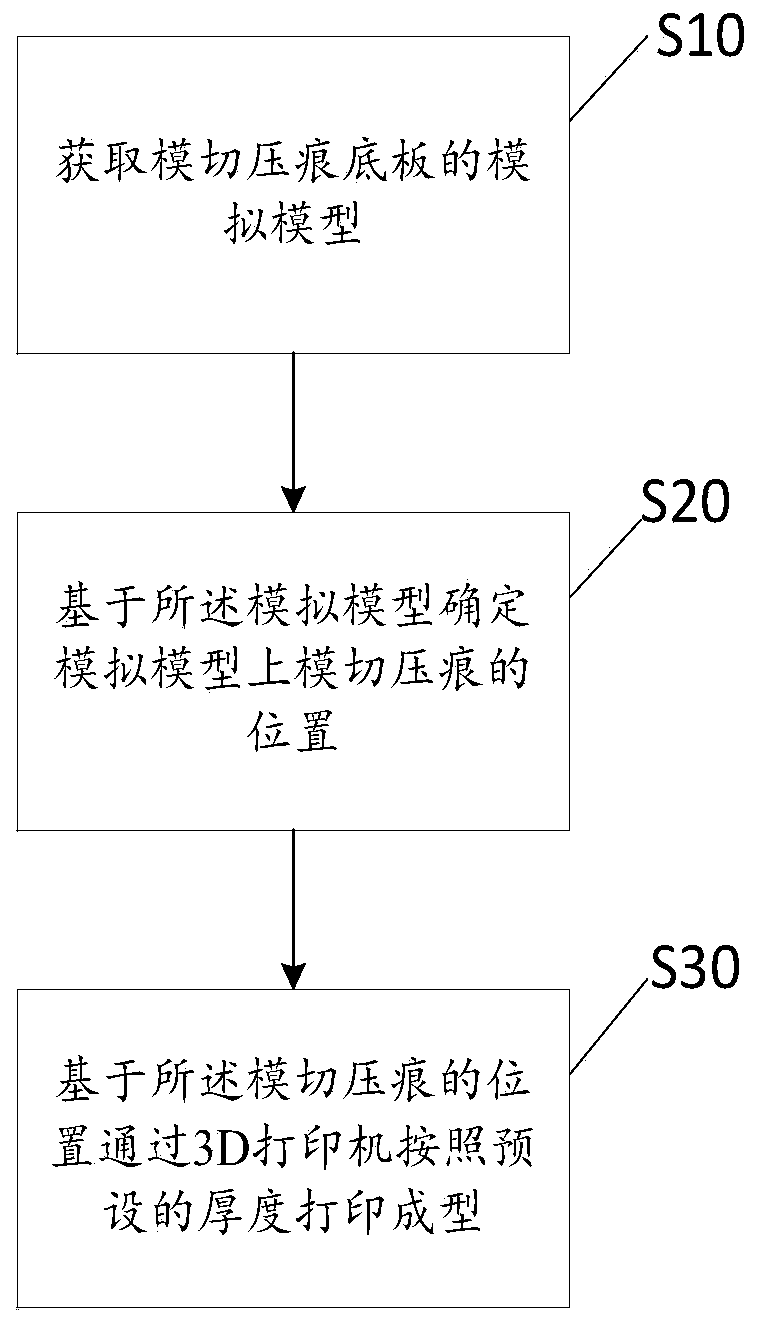

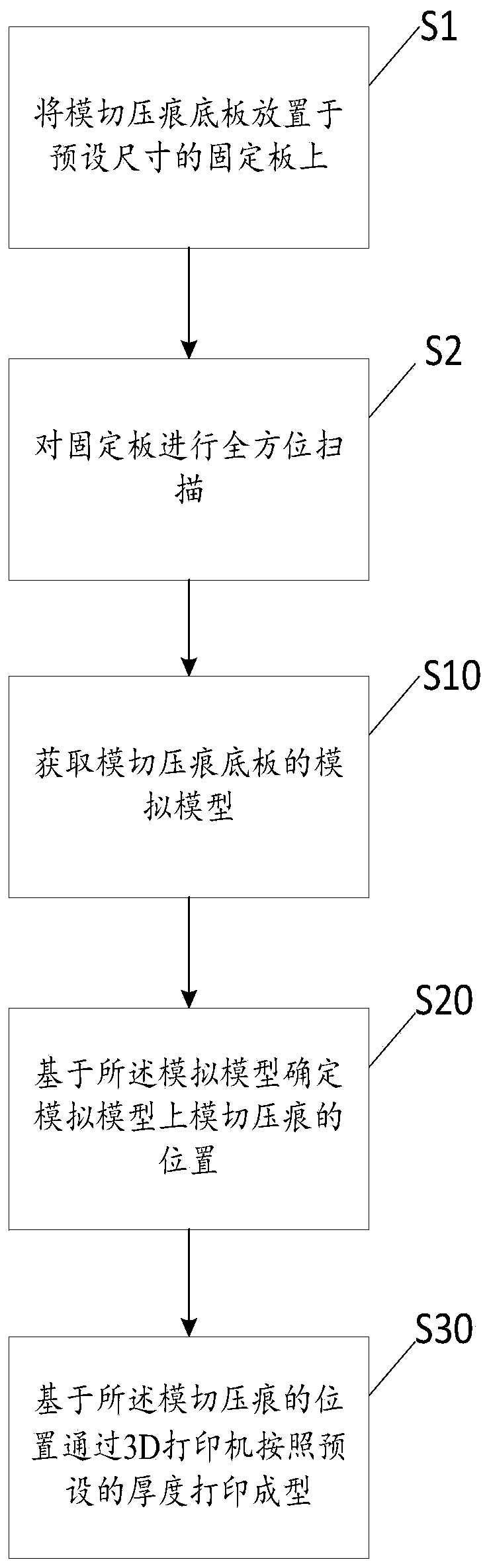

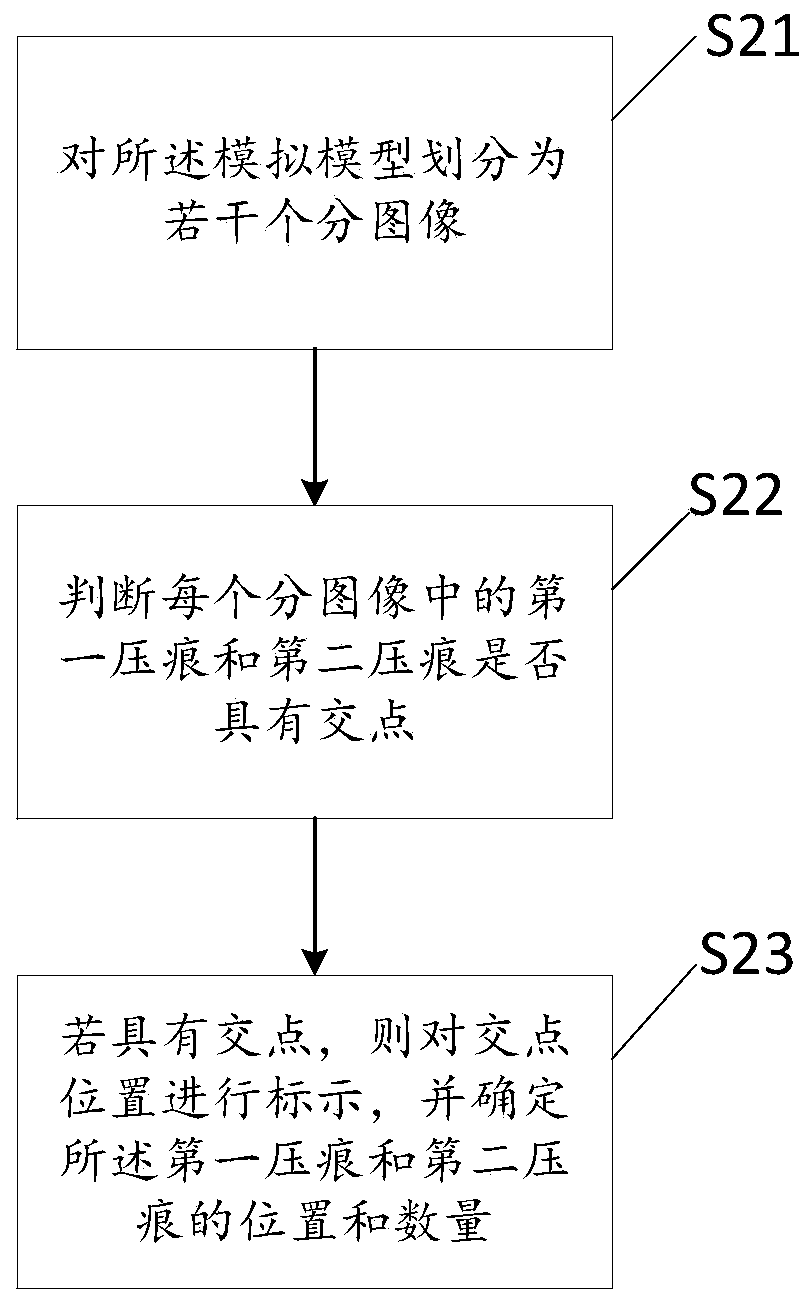

[0035] refer to figure 1 , figure 1 It is a schematic flow chart of the first embodiment of the present invention.

[0036] Such as figure 1 Shown, the manufacture method of die-cutting indentation bottom plate of the present invention, comprises the following steps:

[0037] Step S10, obtaining the simulation model of the die-cutting indentation base plate;

[0038] In step S10, the 3D printer is based on the readable production file about the die-cutting and indentation base plate sent by the mobile phone or the computer, and the three-dimensional simulation model is displayed after the production file is opened. That is, the simulation model is a three-dimensional design file. In this paper, the 3D printer is connected to a computer or a mobile phone, and the user sends the graphic design on the computer or th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com