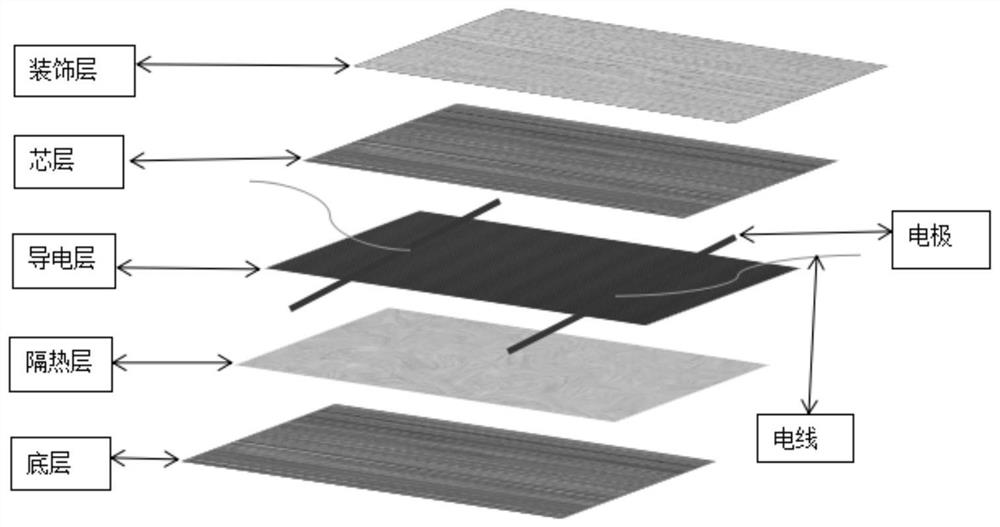

A kind of wooden floor based on carbon paper as heating layer and preparation method thereof

A heat-generating layer and wood-based technology, which is applied in the direction of papermaking, paper, and insulating layers, etc., can solve the problems of inability to generate heat quickly and high resistivity of the heat-generating layer, and achieve the effects of saving consumption, rapid heating, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

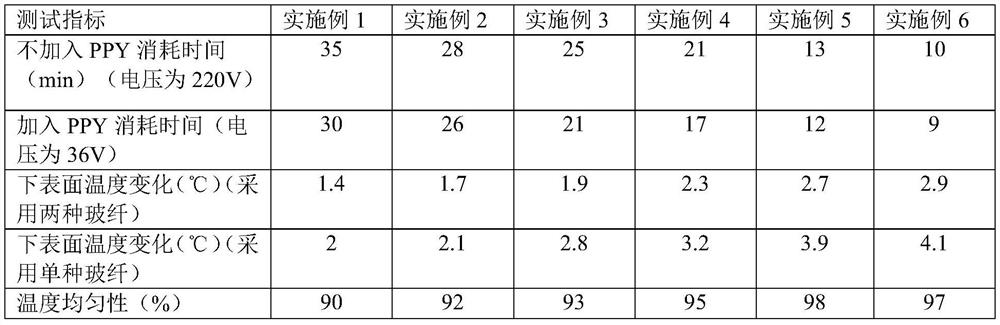

Embodiment 1

[0046] A novel wooden floor based on carbon paper as a heat-generating layer and fiberglass paper as a heat-insulating layer and a preparation process thereof, comprising the following steps:

[0047] (1) Preparation of carbon fiber paper heating layer:

[0048] S1 degreases and degreases 5mm carbon fibers, mixes the degreased carbon fibers with coniferous wood pulp with a beating degree of 40°SR at an absolute dry mass ratio of 1:9, and adds 0.5% dispersant APAM (anionic polyacrylamide), decompressed in a decomposer for 30 minutes to obtain a mixed slurry, which was wet formed, dehydrated and dried to obtain carbon fiber paper;

[0049] S2 gets pyrrole and carries out vacuum distillation pretreatment, and the pyrrole obtained is mixed with sodium dodecylbenzenesulfonate (DBSNa) at a molar ratio of 2:1 and then dissolved in an aqueous solution containing 20% (volume ratio) ethanol, mechanically Stir to make it dissolve, and slowly add 1% ammonium persulfate (APS) of 2mol / L ...

Embodiment 2

[0055] A novel wooden floor based on carbon paper as a heat-generating layer and fiberglass paper as a heat-insulating layer and a preparation process thereof, comprising the following steps:

[0056] (1) Preparation of carbon fiber paper heating layer:

[0057] S1 degreases and degreases 5mm carbon fibers, mixes the degreased carbon fibers with coniferous wood pulp with a beating degree of 40°SR at an absolute dry mass ratio of 3:7, and adds 0.5% dispersant CMC (carboxymethyl cellulose), decompressed in a decomposer for 30 minutes to obtain a mixed slurry, which was wet formed, dehydrated and dried to obtain carbon fiber paper;

[0058] S2 gets pyrrole and carries out vacuum distillation pretreatment, and the pyrrole obtained is mixed with sodium dodecylbenzenesulfonate (DBSNa) at a molar ratio of 2:1 and then dissolved in an aqueous solution containing 20% (volume ratio) ethanol, mechanically Stir to dissolve it, and slowly add 1% 2mol / L ammonium persulfate (APS) of the p...

Embodiment 3

[0064] A novel wooden floor based on carbon paper as a heat-generating layer and fiberglass paper as a heat-insulating layer and a preparation process thereof, comprising the following steps:

[0065] (1) Preparation of carbon fiber paper heating layer:

[0066] S1 degreases and degreases 5mm carbon fibers, mixes the degreased carbon fibers with coniferous wood pulp with a beating degree of 40°SR at an absolute dry mass ratio of 2:3, and adds the dry mass fraction of the mixed pulp 0.5% dispersant APAM (anionic polyacrylamide), decompressed in a decomposer for 30 minutes to obtain a mixed slurry, which was wet formed, dehydrated and dried to obtain carbon fiber paper;

[0067] S2 gets pyrrole and carries out vacuum distillation pretreatment, and the pyrrole obtained is mixed with sodium dodecylbenzenesulfonate (DBSNa) at a molar ratio of 2:1 and then dissolved in an aqueous solution containing 20% (volume ratio) ethanol, mechanically Stir to make it dissolve, and slowly add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

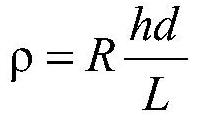

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com