Multi-station flexible hardware machining center and machining method thereof

A processing center and multi-station technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of increased deviation of mechanical claws, increased material costs of enterprises, and affects processing accuracy, so as to avoid errors The effects of processing, reducing labor costs, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The following are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

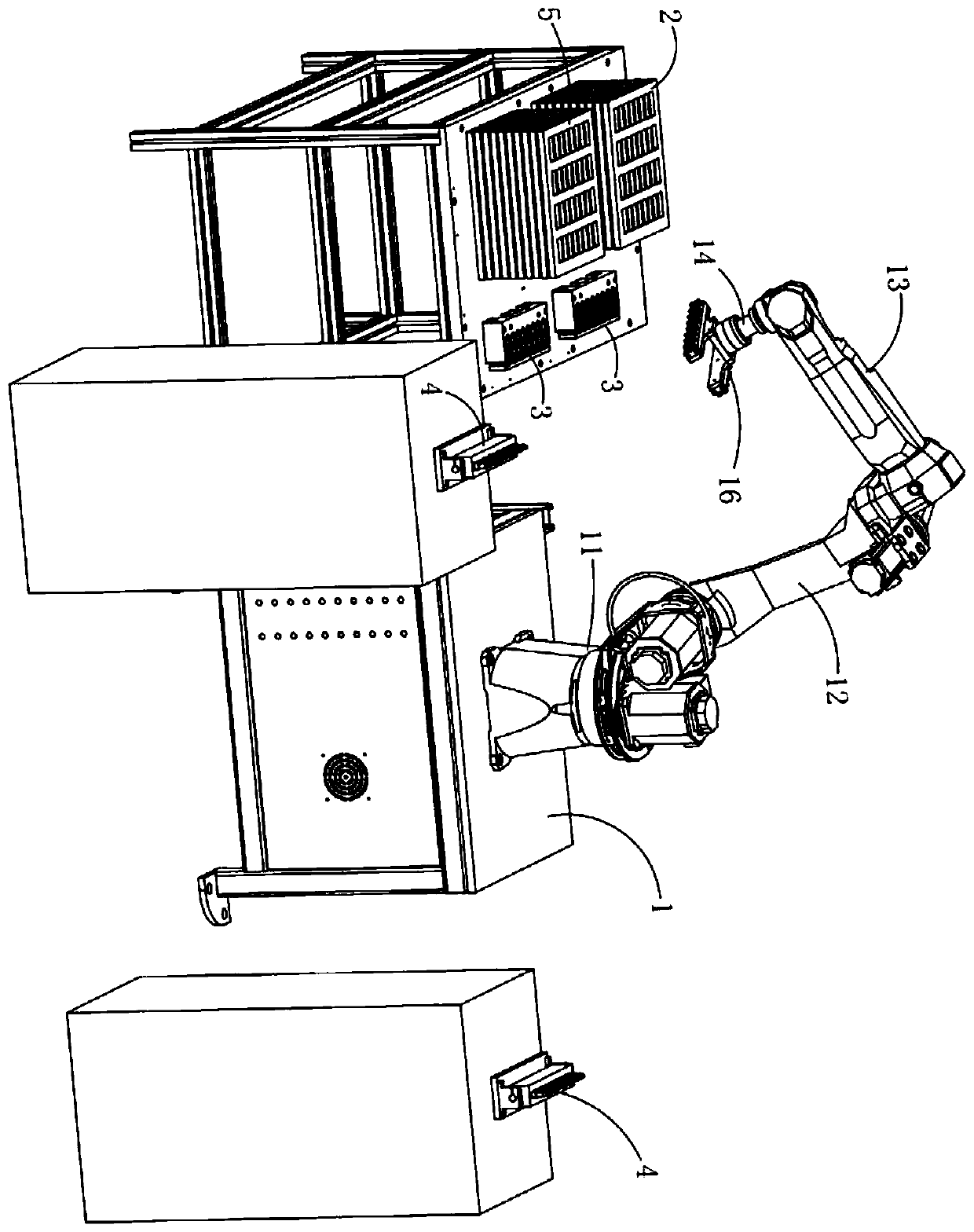

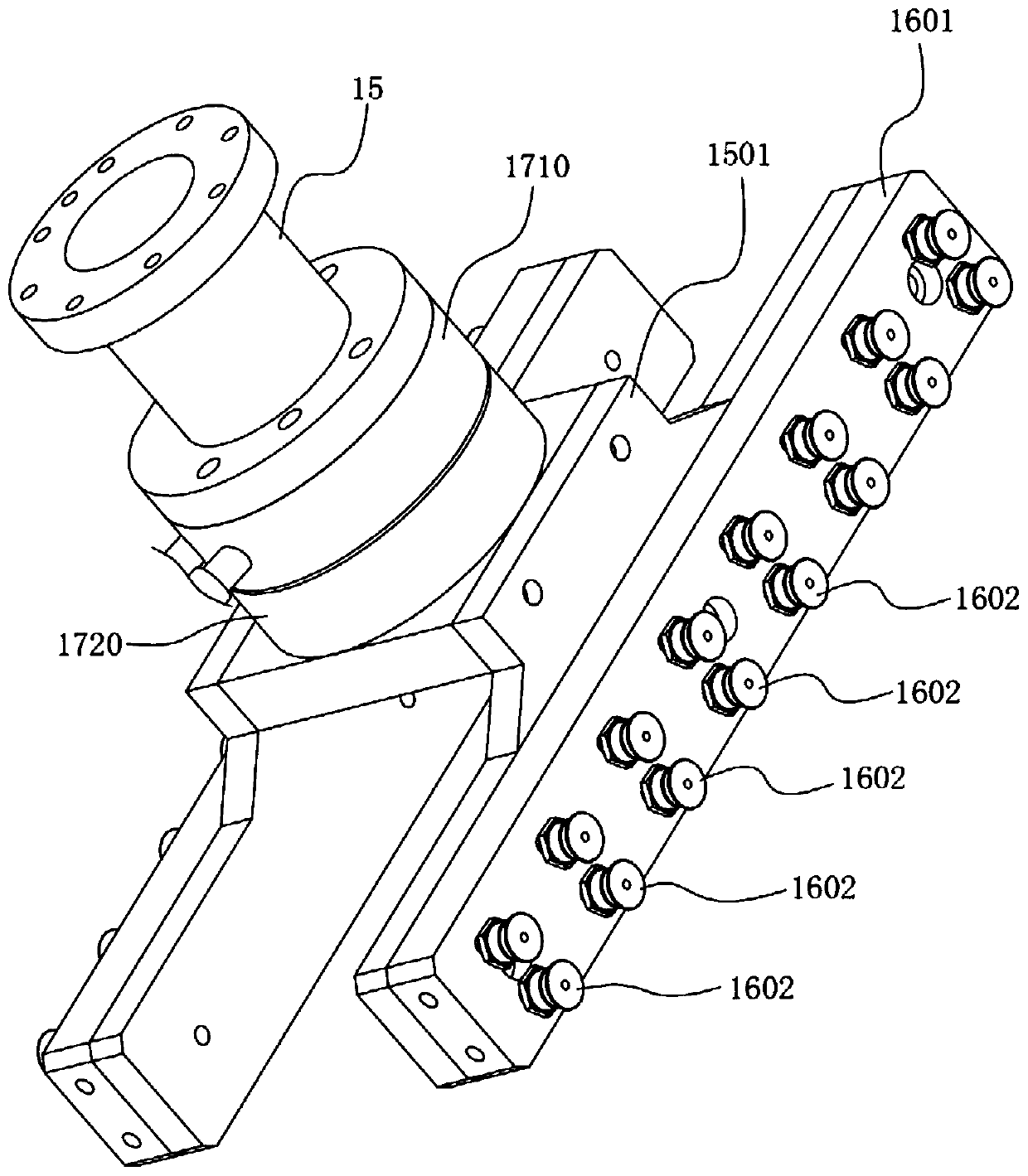

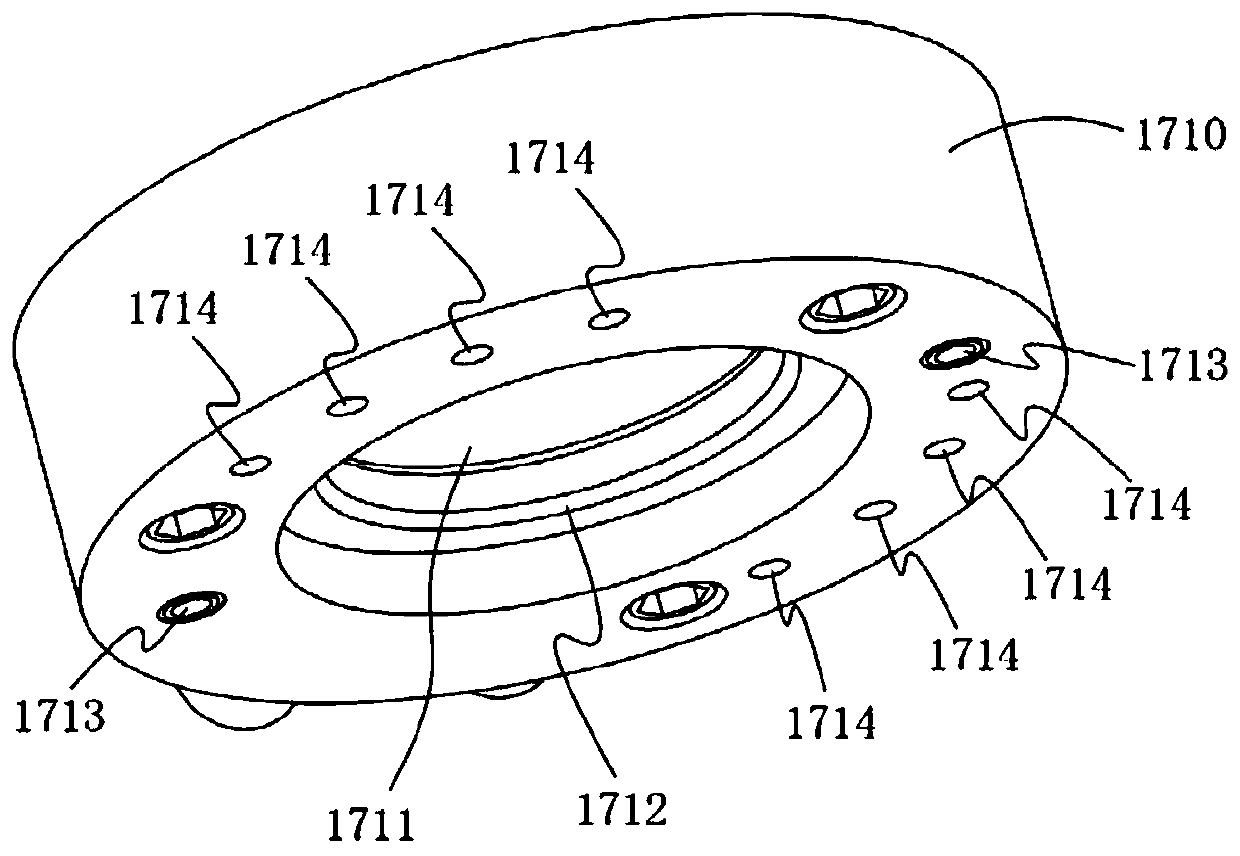

[0050] A multi-station flexible metal processing center, such as Figure 1 to Figure 6 As shown, it includes a manipulator device 1, a blank station 2, a transfer repositioning station, at least one processing station and a finished product station 5, and the manipulator device 1 is used for handling and processing workpieces and for grasping and processing the workpieces. The manipulator device 1 is provided with Manipulator gripper 16, manipulator gripper 16 comprises at least one gripper unit, and each gripper unit is provided with a plurality of gripper stations respectively, and in the same gripper unit, each gripper station distribution forms a clamping size; Blank station 2, uses For placing the workpieces to be processed, the blank station 2 is provided with at least one blank container, and a plurality of workpieces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com