Wide flow multi-flow high-efficiency gas-liquid separator

A technology of gas-liquid separator and separator, which is applied in the field of nuclear energy, can solve the problems of lack of high-efficiency operation and single applicable flow pattern of the separator, and achieve the effects of improving separation efficiency, reducing separation pressure, and high-efficiency separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in more detail below in conjunction with accompanying drawing example:

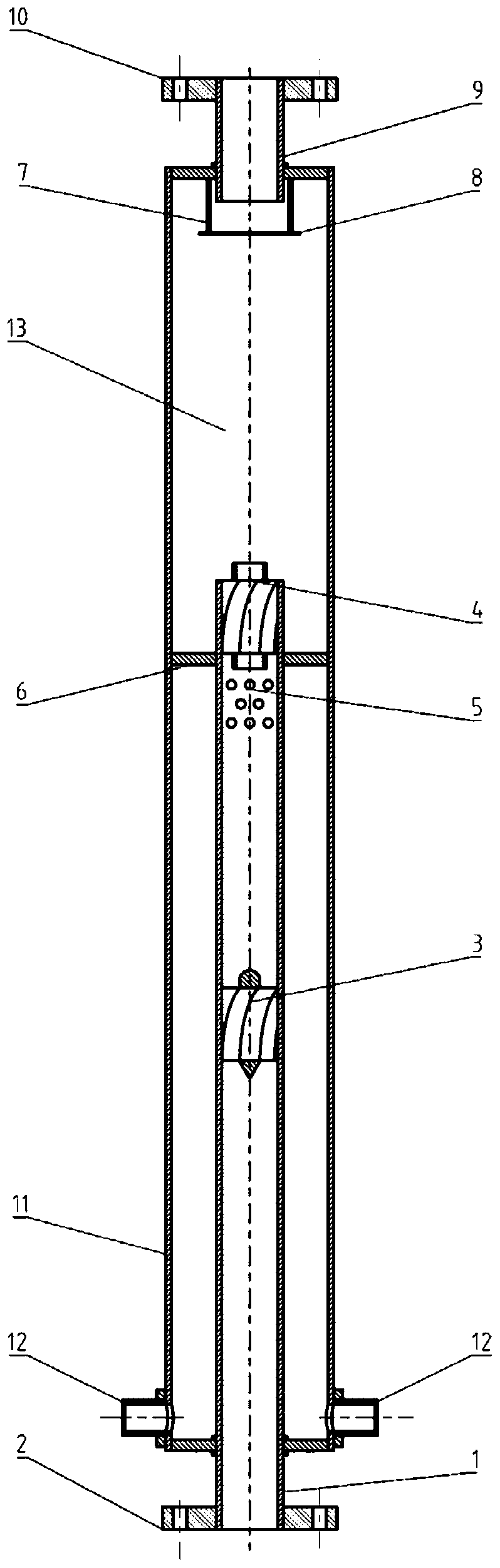

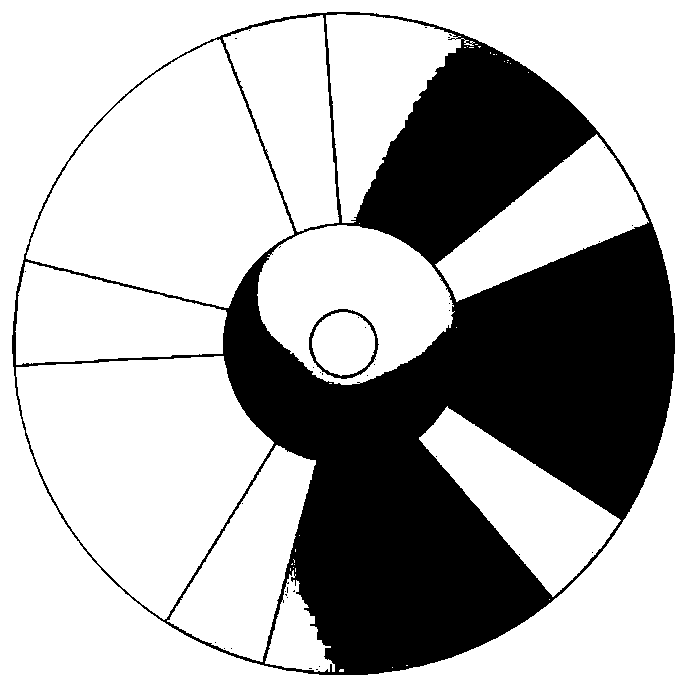

[0024] combine Figure 1-3b , a combined multi-flow type high-efficiency gas-liquid separator provided by the present invention includes, inner cylinder body 1, inlet flange 2, primary impeller 3, secondary impeller 4, liquid discharge section 5, anti-vibration strip 6, Separation baffle tension rib 7, separation baffle 8, separator gas phase outlet 9, outlet flange 10, outer cylinder 11, separator liquid phase outlet 12, separator outer cylinder separation chamber 13. The main structure is composed of two layers of mutually nested cylinder structures, the outer layer is the outer cylinder 11, the inner layer is the inner cylinder 1, the anti-vibration strip 6 is installed between the inner cylinder 1 and the outer cylinder 11, and the gas phase outlet of the separator 9 is arranged on the top of the separator, and the liquid phase outlet 12 of the separator is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com