Double-cooking food processor

A food processor with dual technology, applied to steam cooking utensils, utensils for frying things in oil, household utensils, etc., can solve the problems of undercooked frying, no soft feeling, hard steamed buns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

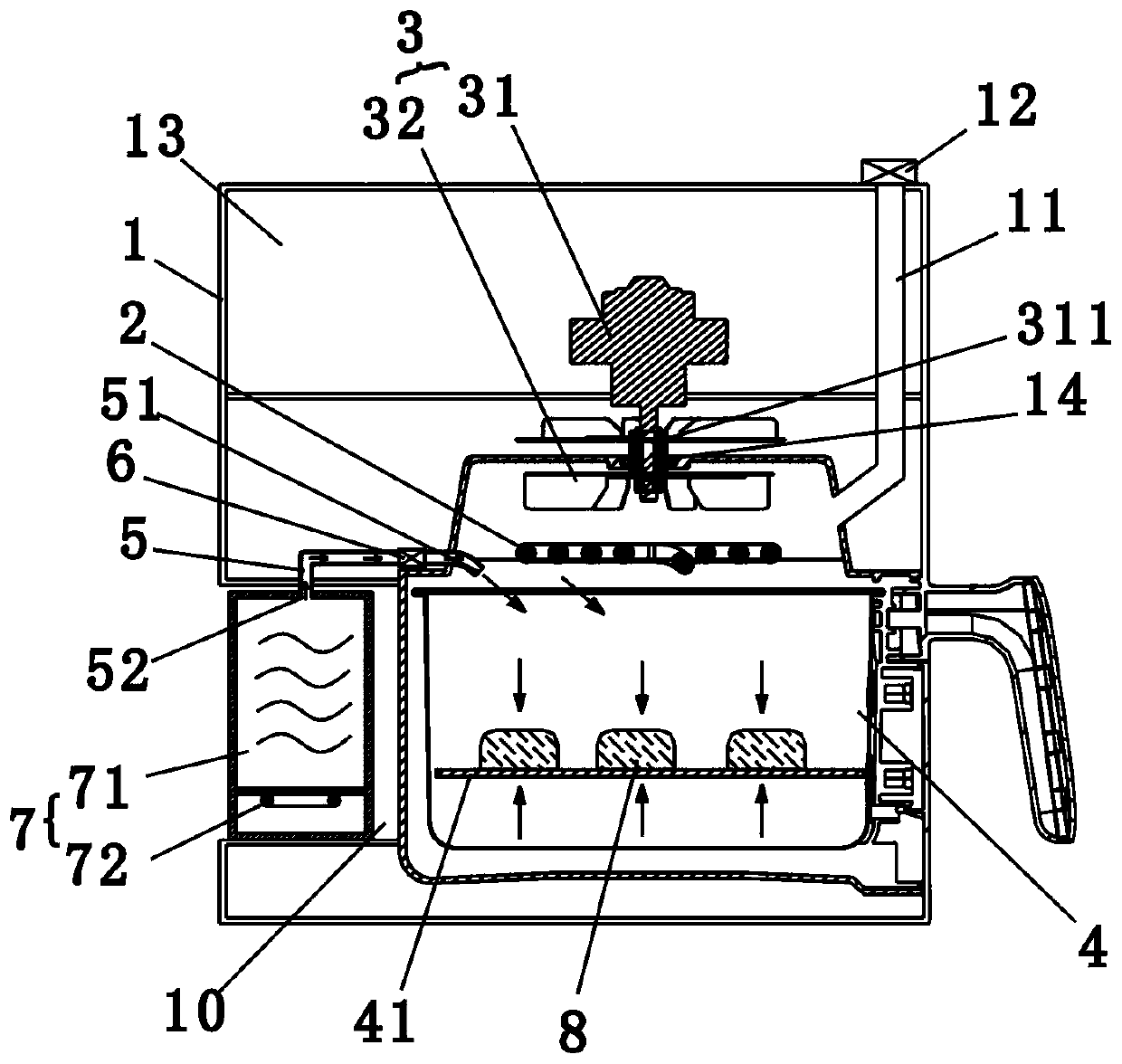

[0030] Such as figure 1 Shown is a schematic structural diagram of the first embodiment of the present invention. A food processing machine, comprising a body 1, a heating device 2 installed in the body 1, a fan assembly 3 blowing toward the heating device 2, and a fryer assembly 4 located below the heating device 2, the side wall of the body 1 is provided with There is an opening installation chamber (not marked in the figure), the fryer assembly 4 is detachably inserted in the installation chamber, a steam pipe 5 is installed in the body 1, and the outlet end 51 of the steam pipe faces the fryer The component 4 is provided, and the on-off of the steam pipe 5 is controlled by the control valve component 6 .

[0031] In this embodiment, the food processing machine also includes a steam generating device 7, which communicates with the inlet end 52 of the steam pipe 5, and the body 1 is provided with an accommodating chamber 10 for accommodating the steam generating device 7, w...

Embodiment 2

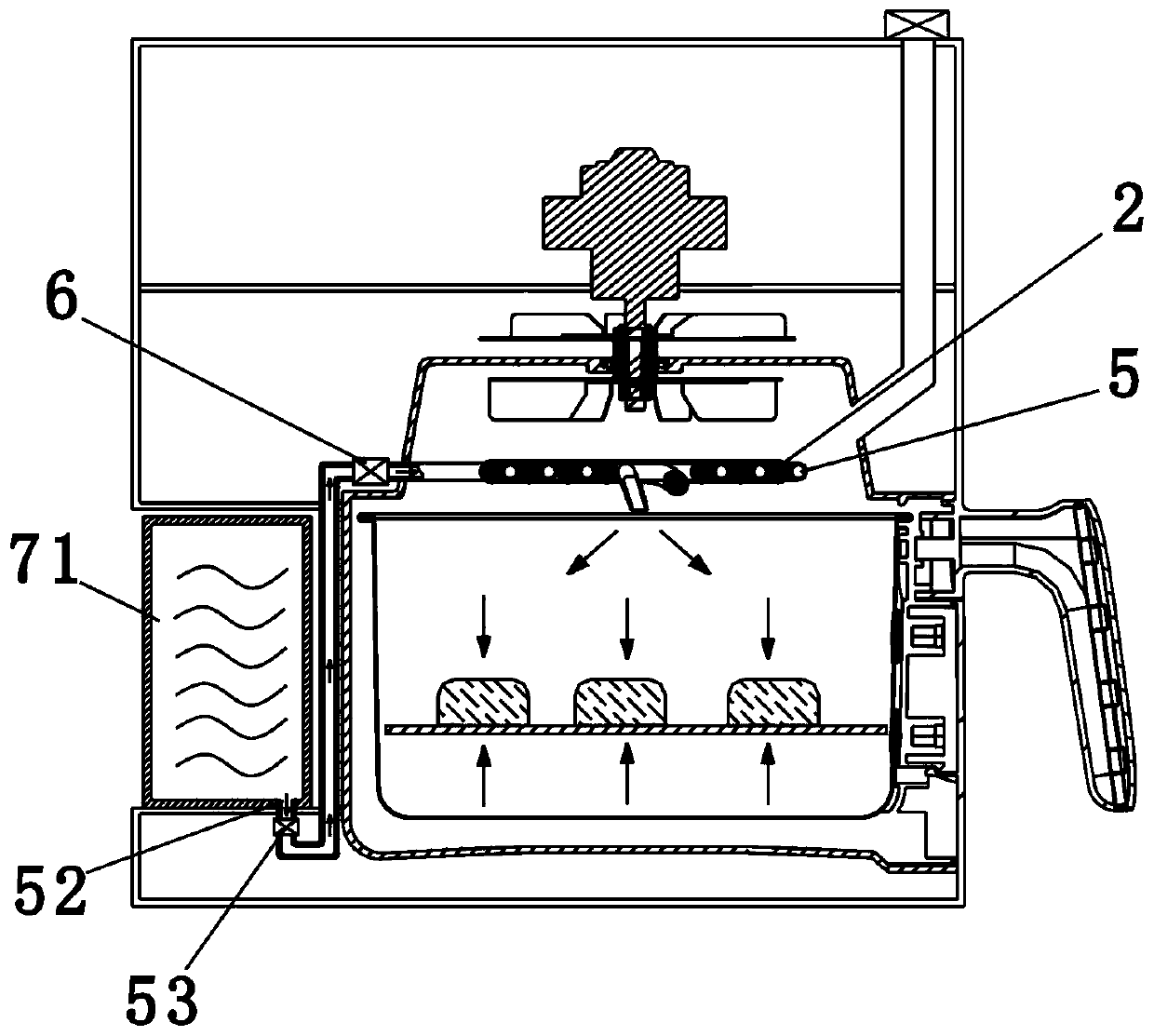

[0037] Such as figure 2 Shown is a schematic structural diagram of the second embodiment of the present invention. The difference between this embodiment and Embodiment 1 is that the steam pipe 5 is a heat-resistant pipe, the heating device 2 is integrated with the steam pipe 5, and the heating device 2 can heat the water in the steam pipe 5 into steam . In this embodiment, the heating device 2 is a heating tube, and the heating tube and the steam tube 5 are welded and fixed side by side, and are bent together into a circular pie shape.

[0038] At the same time, in the present embodiment, the inlet end 52 of the steam pipe 5 communicates with the water tank 71, and the inlet end 52 of the steam pipe is located below the liquid level in the water tank 71. Water pump 53 and control valve assembly 6 for opening and closing the steam pipe.

[0039]For this embodiment, the heating device is blown by the fan assembly to realize the cooking of the ingredients in the fryer assemb...

Embodiment 3

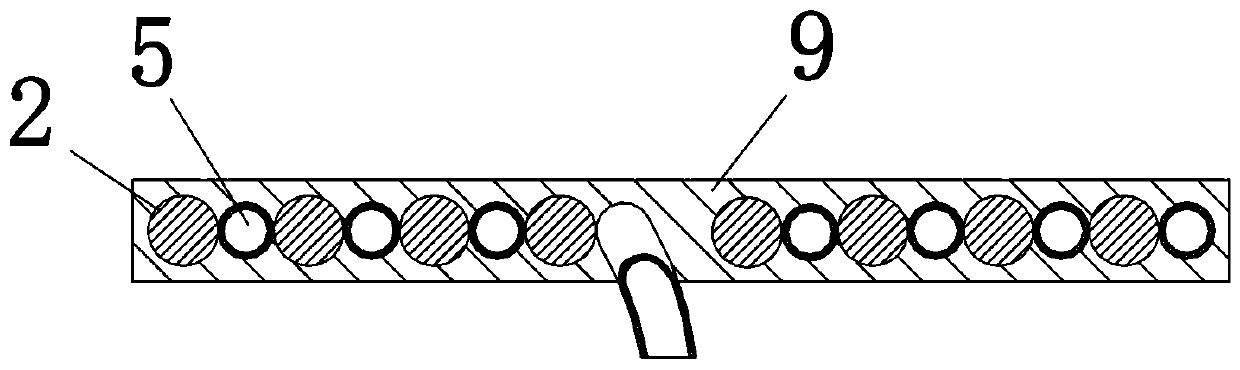

[0042] Such as image 3 Shown is a schematic structural view of the third embodiment of the present invention. The difference between this embodiment and Embodiment 2 is that in this embodiment, the heating device 2 is a heating pipe, and the heating pipe and the steam pipe 5 are fixed into one body through the aluminum matrix 9, wherein the aluminum matrix 9 heats the The tube and the steam tube 5 are hidden inside the aluminum base 9, so that the outer wall of the steam tube 5 can be heated in all directions, and the heating efficiency is higher. Even if the power of the heating tube is small, the water in the steam tube 5 can be heated to steam.

[0043] In this embodiment, in addition to being used to fix the heating tube and steam tube, the aluminum substrate also has the function of realizing omni-directional heating of the steam tube, with higher heating efficiency and more uniform heating, and the heat generated by the heating tube can also be more concentrated in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com