Liquid separating head

A liquid dispensing head, integrated technology, applied in refrigeration and liquefaction, fluid circulation arrangement, refrigeration components, etc., can solve the problems of inner wall damage, strict installation method, incomplete evaporation, etc., to reduce flow resistance and flow noise, The effect of improving performance and reliability, and saving processing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

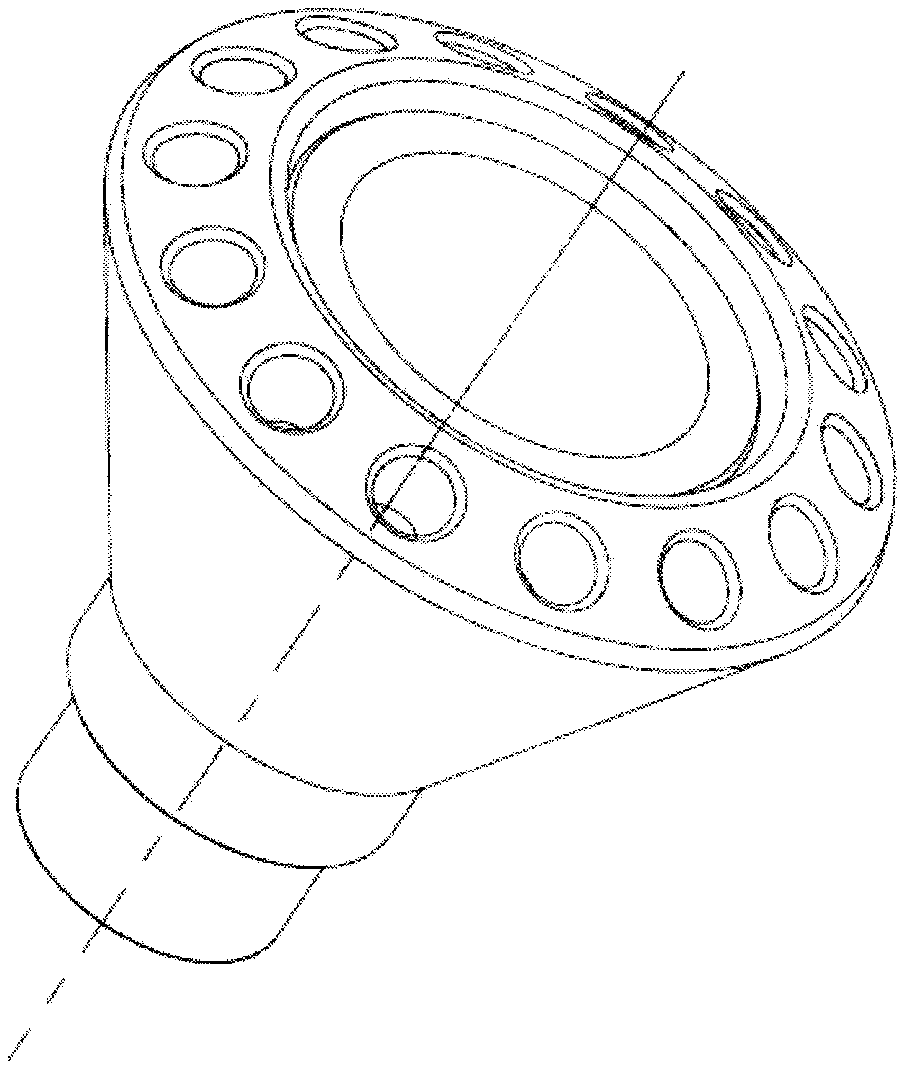

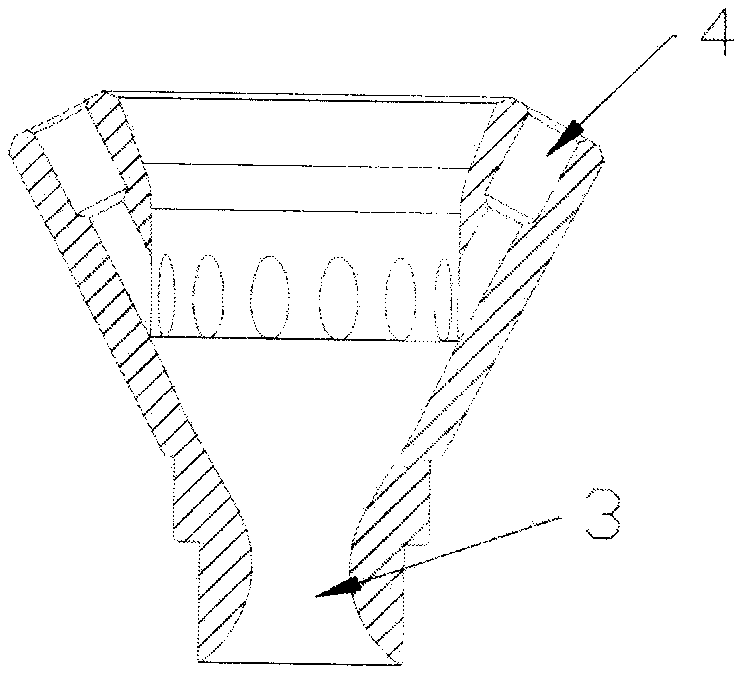

[0025] Implementation method: such as figure 1 , 2 , 3, 4, and 5, the shunt block 2 is press-pressed into the body 1 of the dispenser head and welded and sealed into one body, the fluid inlet 3 at one end of the body 1 of the dispenser head, and the other end of the body 1 of the dispenser head is provided with several Distributing holes 4, the distributing holes 4 are equal in size and uniformly distributed in a conical shape, and the liquid distribution pipe 5 is inserted into the distributing holes 4 and welded and sealed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com