Beam-column concrete pouring dense-type combined formwork in building construction

A building construction and concrete technology, which is applied in the direction of construction, building structure, formwork/formwork/work frame, etc., can solve the problems of low connection strength, difficult disassembly and assembly of combined steel formwork, and large joints, so as to reduce labor intensity , The assembly is simple and easy, and the effect of improving the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

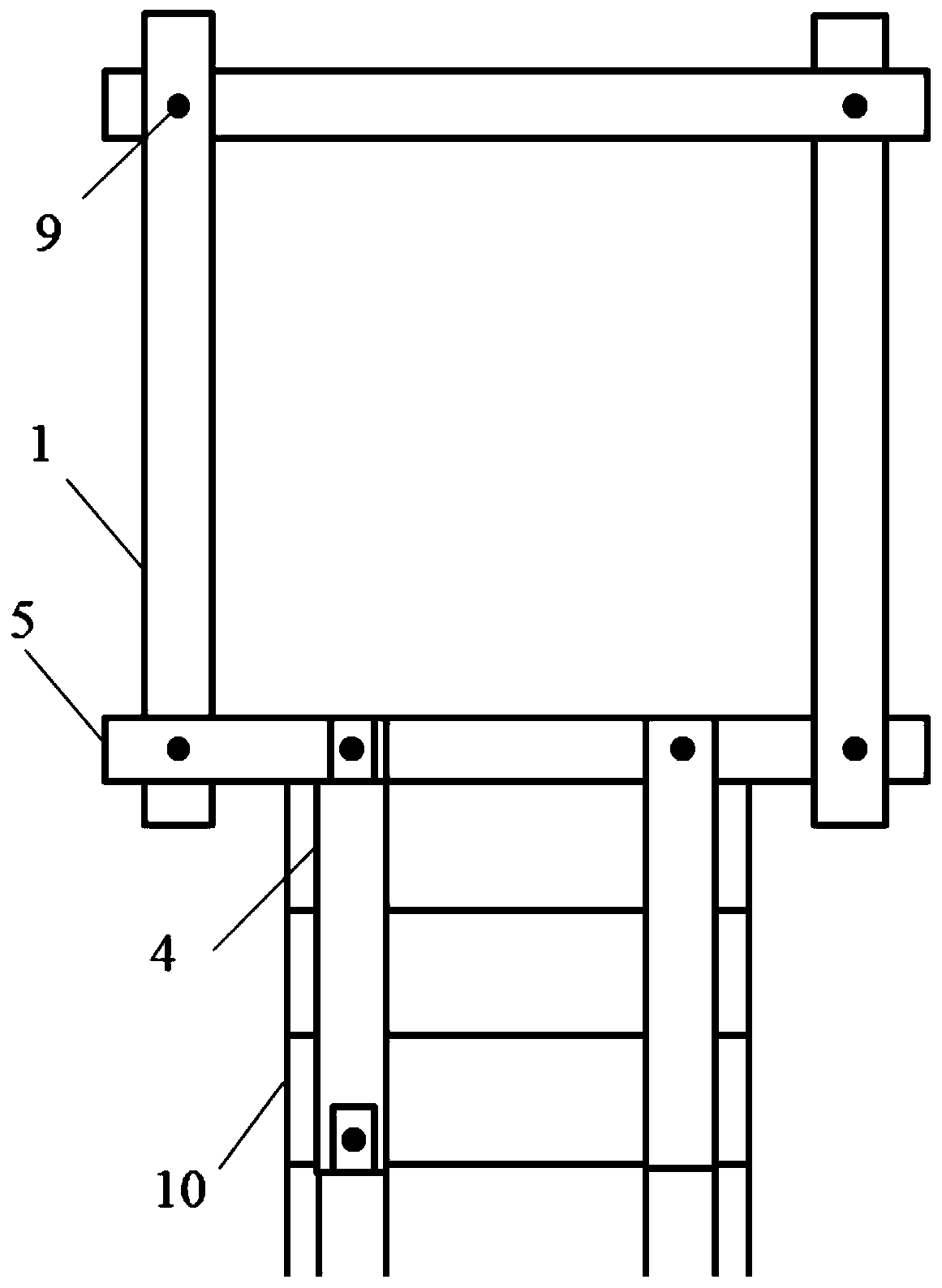

[0018] A kind of building construction beam column concrete pouring compact combined formwork, see Figure 1-5 , including a column formwork 1, the column formwork 1 is formed by fastening a plurality of column modules 2 into a rectangular frame, the upper end of the column formwork 1 is provided with an opening, the opening is provided with a beam formwork 3, and the cross section of the beam formwork 3 is U-shaped structure, the opening of the beam formwork 3 faces upwards, and the end of the beam formwork 3 is connected to the opening of the column formwork 1 through the connecting plate 5 .

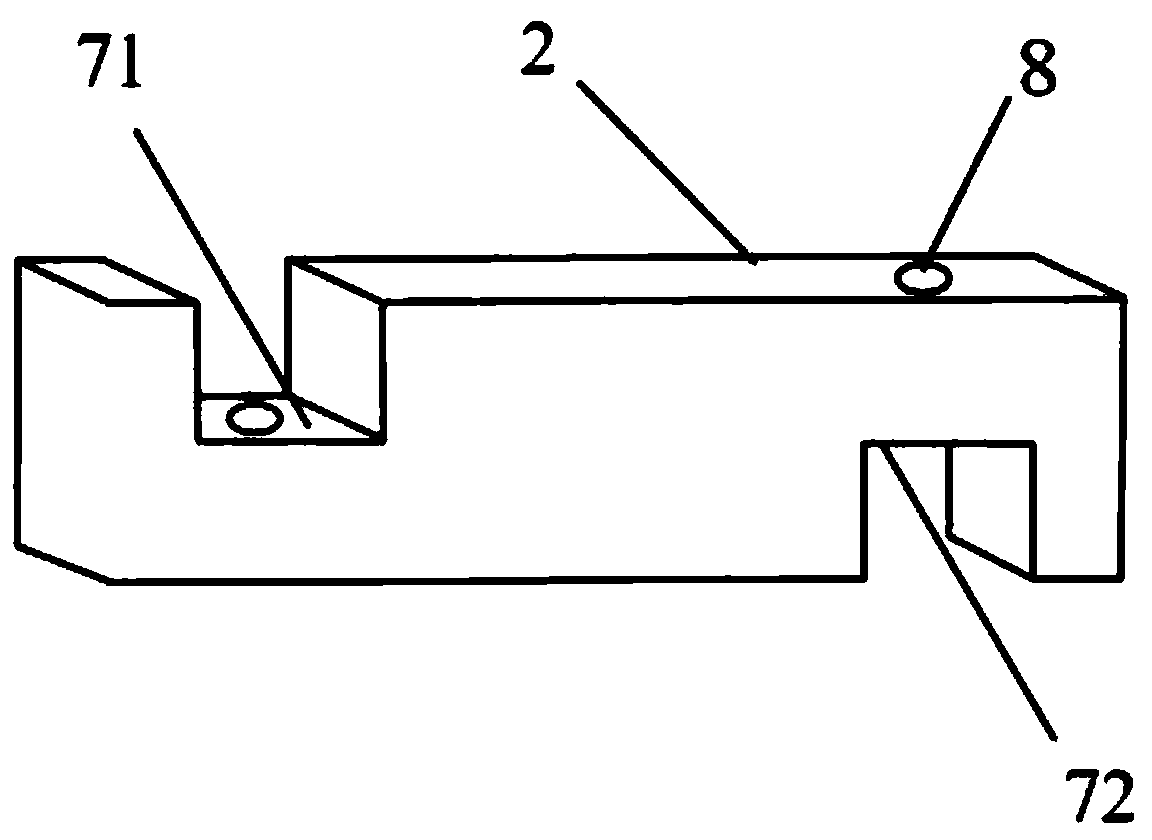

[0019] In order to facilitate the connection between the column templates 1 and ensure the connection strength, the two ends of the column module 2 are provided with groove I71 and groove II72. The two grooves 7 are of different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com