A kind of mechanochemical extraction method for preparing naphthalene pyrone crude extract from iron-clad gold

A naphthopyrone and mechanochemical technology, which is applied in the field of mechanochemical extraction for the preparation of naphthalene pyrone crude extract, can solve the problems of reducing the extraction rate, and achieve the effects of improving the extraction yield, low cost, and rapid extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

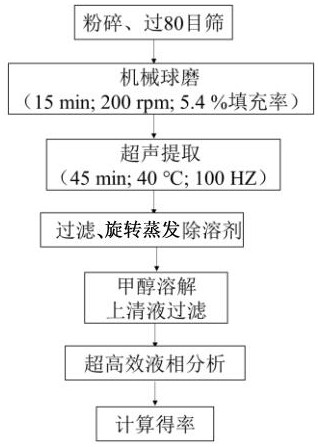

Method used

Image

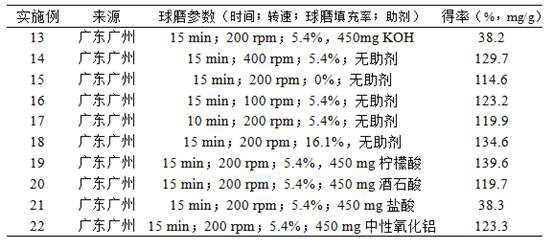

Examples

Embodiment 1

[0038] The iron-clad gold produced in Guangzhou, Guangdong is crushed and passed through an 80-mesh sieve to obtain iron-clad gold powder with a mesh size greater than 80 mesh. Add 0.30 g of the iron-clad gold powder into the stainless steel ball milling tank, add 10 stainless steel balls with a diameter of 8 mm (the filling rate of the ball mill is 5.4%), the ball milling time is 15 min, and the ball milling speed is 200 rpm.

[0039] Weigh 0.10 g of the ball-milled powder and mix it with ethanol aqueous solution (V ethanol: V water = 60 / 40) according to the ratio of solid to liquid at 1:50 (the unit of solid to liquid ratio is g / mL), and then place it in a water bath at 40°C for ultrasonication Extracted for 45 min (ultrasonic frequency 100HZ), filtered, and the filtrate was removed by rotary evaporation to obtain 11 mg of naphthalene pyrone crude extract.

[0040] Take 10.59 mg of the crude naphthalene pyrone extract obtained above and dissolve it in 1 mL of methanol, then ...

Embodiment 2

[0043] The iron-clad gold produced in Guangzhou, Guangdong is crushed and passed through an 80-mesh sieve to obtain iron-clad gold powder with a mesh size greater than 80 mesh. Add 0.31 g of the iron-clad gold powder into the stainless steel ball mill tank, add 15 stainless steel ball milling beads with a diameter of 8 mm (the ball milling filling rate is 8.0%), the ball milling time is 15 min, and the ball milling speed is 200 rpm.

[0044] Weighed 0.10 g of the ball-milled powder, and the rest of the subsequent ultrasonic extraction conditions and ultra-high performance liquid chromatography conditions were the same as in Example 1 to obtain 11 mg of crude naphthalene pyrone extract. Calculation of the yield of rhodofusarmycin-6-O-α-L-rhamnosyl-(1-6)-O-β-D-glucopyranoside in the crude extract was 141.9% (mg / g) .

[0045] Comparing Example 2 and Example 1, it can be seen that when 15 stainless steel ball milling beads are added (the filling rate of the ball mill reaches 8.0%...

Embodiment 3

[0047] The iron-clad gold produced in Guangzhou, Guangdong is crushed and passed through an 80-mesh sieve to obtain iron-clad gold powder with a mesh size greater than 80 mesh. Add 0.30 g of the iron-clad gold powder into the stainless steel ball mill tank, add 20 stainless steel ball milling beads with a diameter of 8 mm (the filling rate of the ball mill is 10.7%), the ball milling time is 15 min, and the ball milling speed is 200 rpm.

[0048] Weigh 0.10 g of the ball-milled powder, and the rest of the subsequent ultrasonic extraction conditions and ultra-high performance liquid chromatography conditions are the same as in Example 1 to obtain 10 mg of crude naphthalene pyrone extract. Calculate the yield of rhodofusarmycin-6-O-α-L-rhamnosyl-(1-6)-O-β-D-glucopyranoside in the crude extract as 138.5% (mg / g) .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com