Elastic garden anti-corrosion wood preparation system

A preparation system and anti-corrosion wood technology, applied in wood treatment, wood heating, manufacturing tools, etc., can solve the problems of low degree of automation, achieve the effects of saving labor costs, ensuring the quality of treatment, and improving the efficiency of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

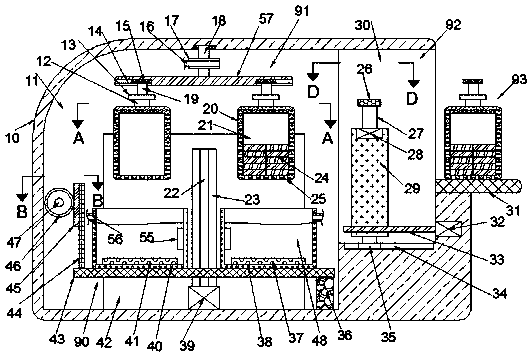

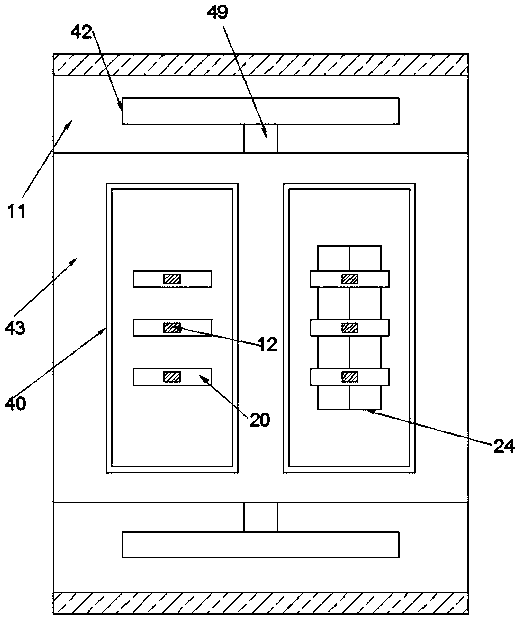

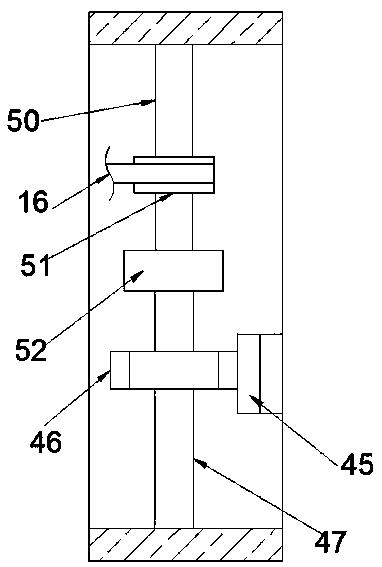

[0024] Combine below Figure 1-4 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0025] A kind of flexible garden preservative wood preparation system described in conjunction with accompanying drawings 1-4 mainly includes a treatment box 10 and a treatment chamber 11 arranged in the treatment box 10, and a treatment mechanism 90 is arranged in the treatment chamber 11 . Transposition mechanism 91, the processing box 10 is provided with a feeding chamber 30 communicated with the processing chamber 11, and the feeding chamber 30 is provided with a feeding mechanism 92;

[0026] The processing mechanism 90 includes a cold tank 40, a hot tank 38, a refrigeration unit 41, and a heating unit 37. Both the cold tank 40 and the hot tank 38 are provided with an anti-corros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com