Resistance welding machine for continuous welding seam heat treatment

A resistance welding machine and connecting column technology, applied in resistance welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of waste, high temperature, too large temperature difference, etc., to enhance heating effect, enhance heat transfer efficiency, The effect of fast transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

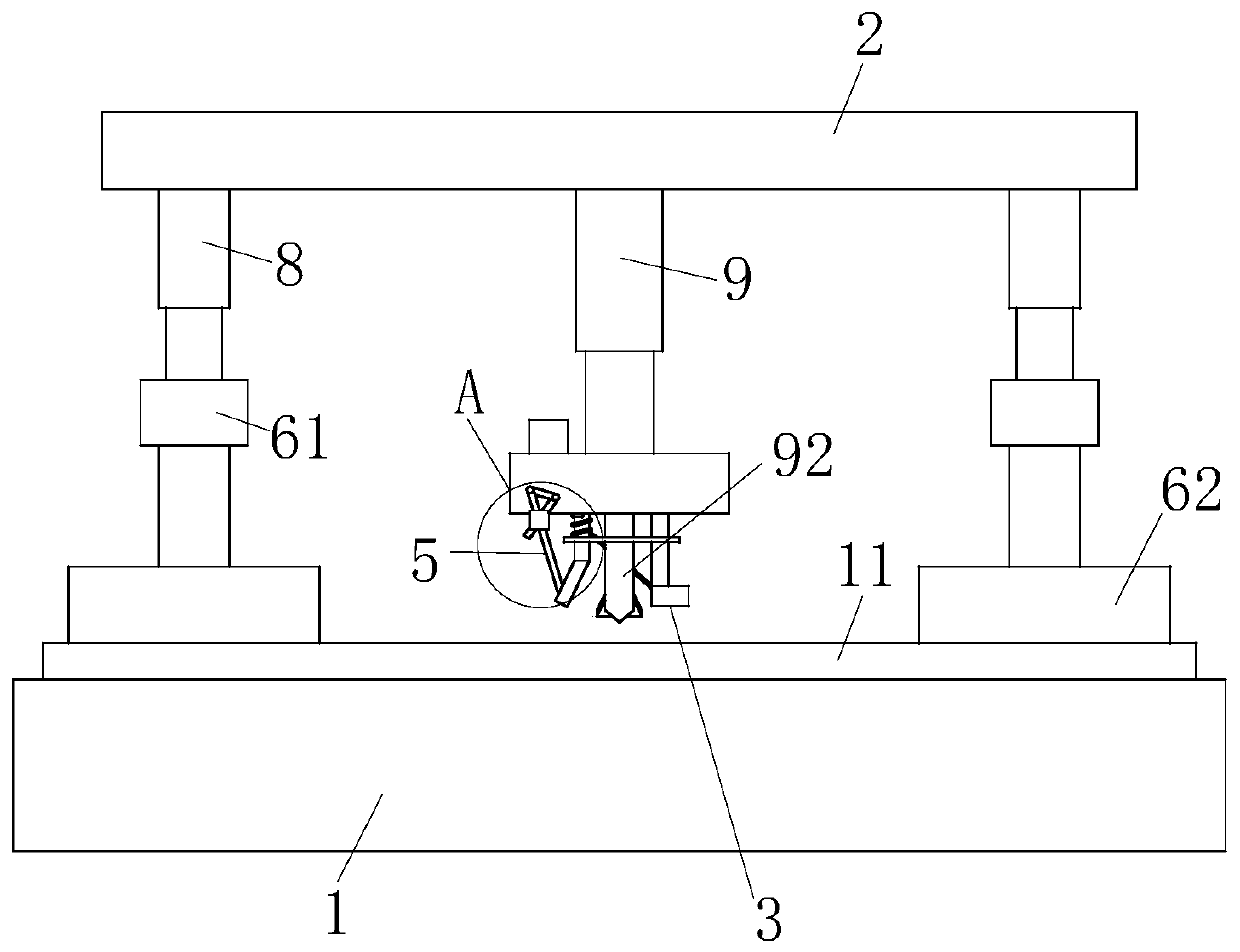

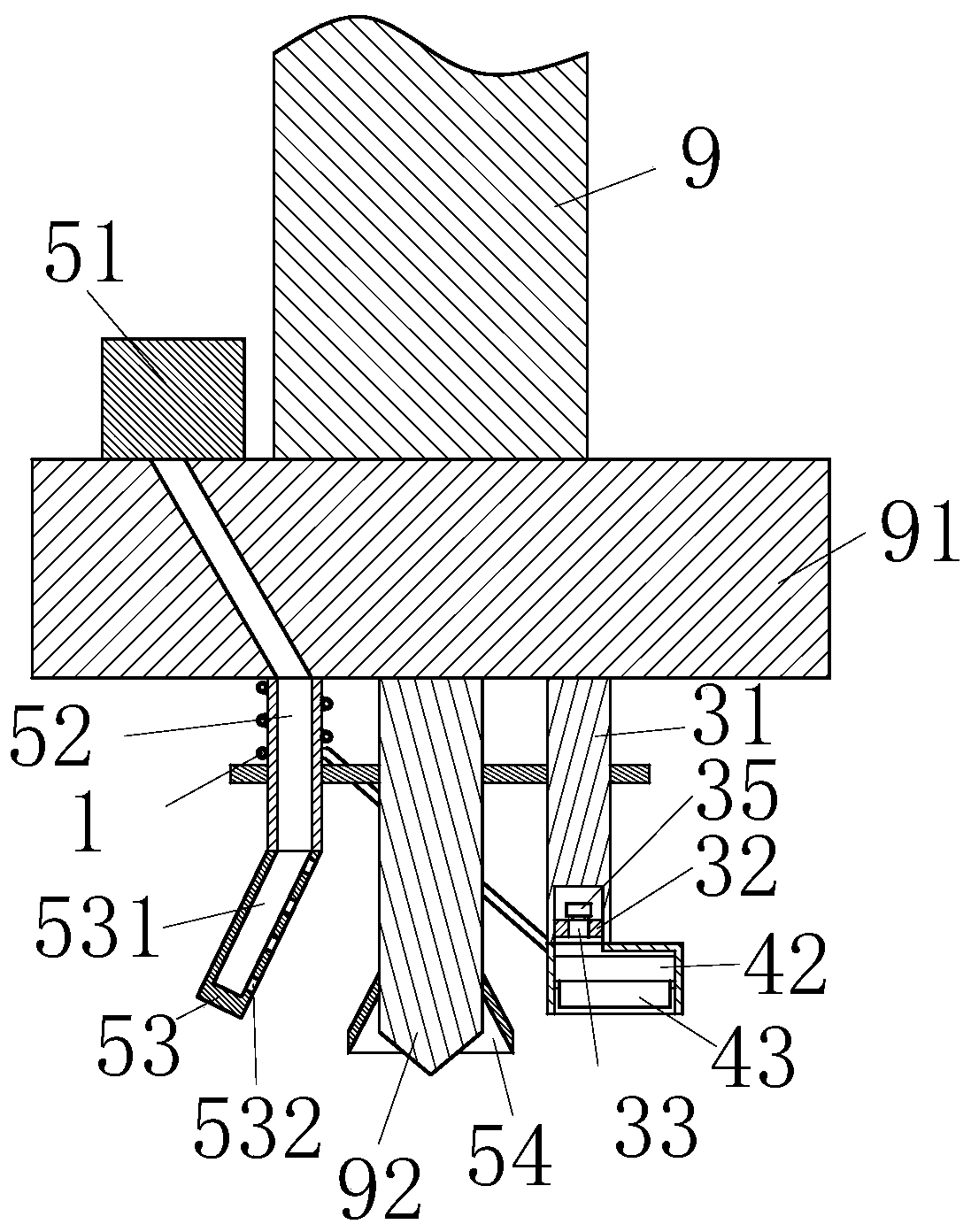

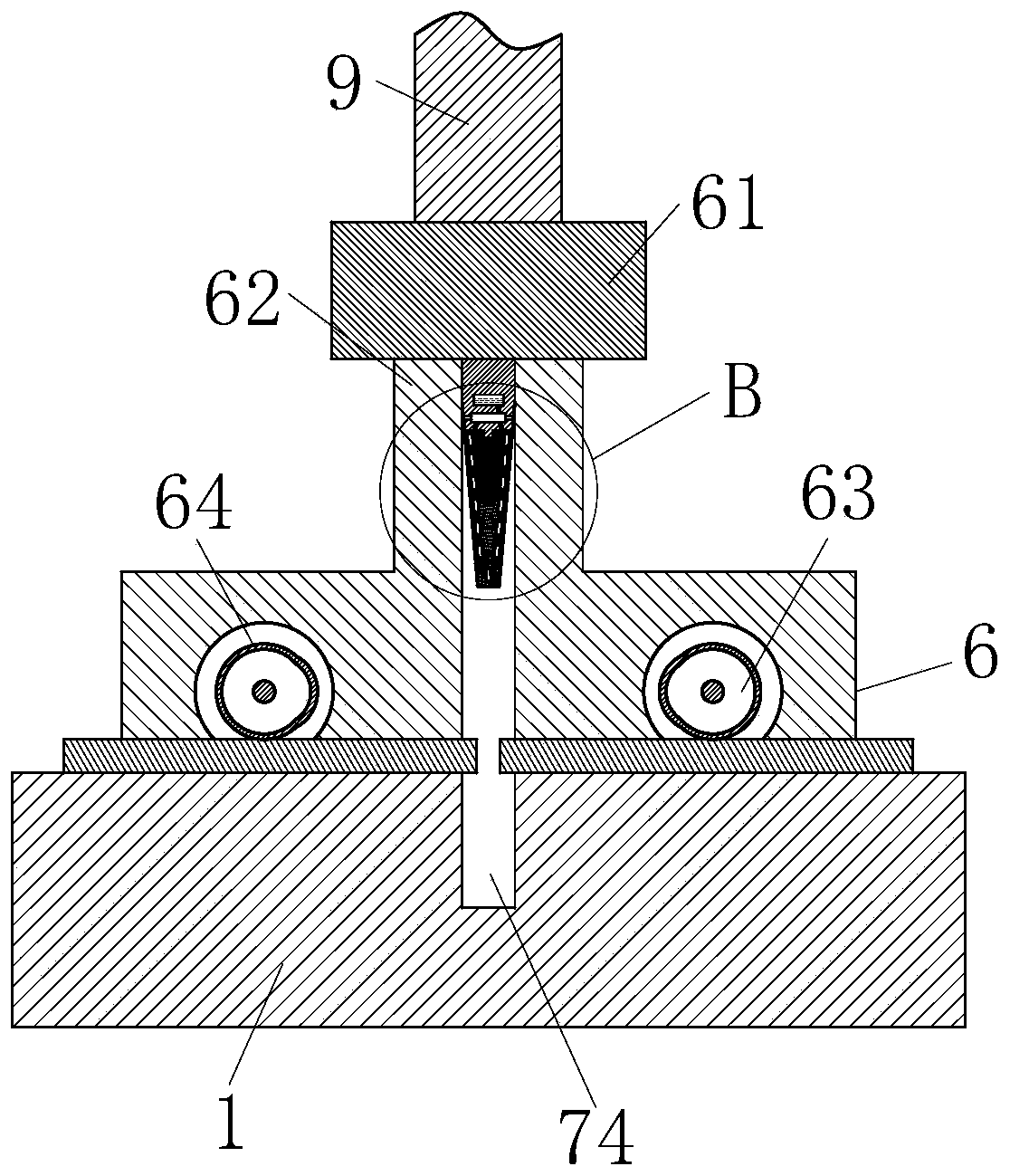

[0021] use Figure 1-Figure 6 A continuous seam heat treatment resistance welding machine according to an embodiment of the present invention will be described as follows.

[0022] Such as Figure 1-Figure 6 As shown, a continuous weld seam heat treatment resistance welding machine according to the present invention includes a base 1, a mounting bracket 2, a preheating mechanism 3, a heat treatment mechanism 4, a heat preservation mechanism 5, a fixing mechanism 6 and a spacing adjustment mechanism 7; A welding plate 11 is placed on the upper surface of the base 1; the upper surface of the left and right ends of the welding plate 11 is provided with a fixing mechanism 6; the upper end of the fixing mechanism 6 is fixedly connected to both ends of the lower surface of the mounting bracket 2 through the first hydraulic rod 8; The lower surface of the middle part of the mounting bracket 2 is fixedly connected with a welding block 91 through the second hydraulic rod 9; the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com