Method for preparing bean dreg fermented bean curd from soybean dregs

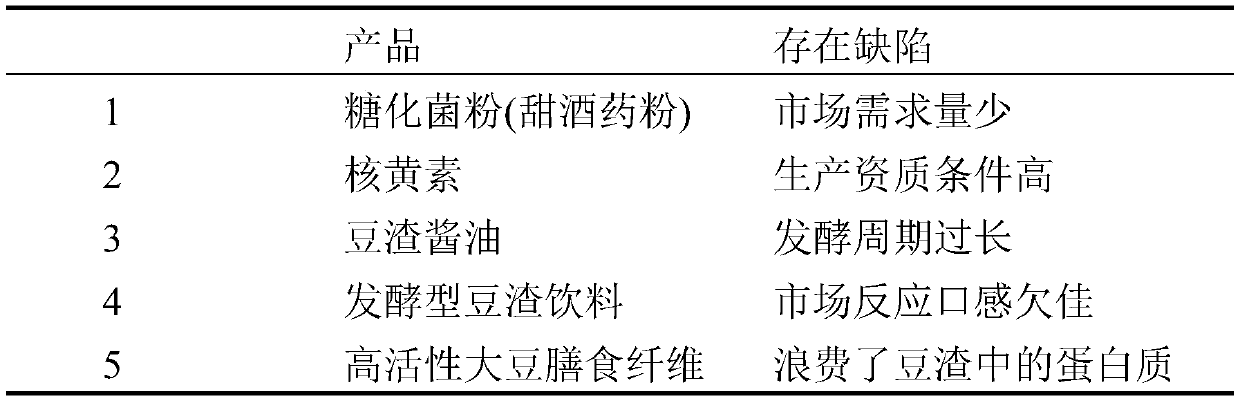

A technology of soybean dregs and bean dregs, which is applied in the field of food manufacturing, can solve the problems of inability to effectively improve the taste of bean dregs, low economic benefits, and low edible value of bean dregs, and achieve low overall cost, high-value full utilization, and increased utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

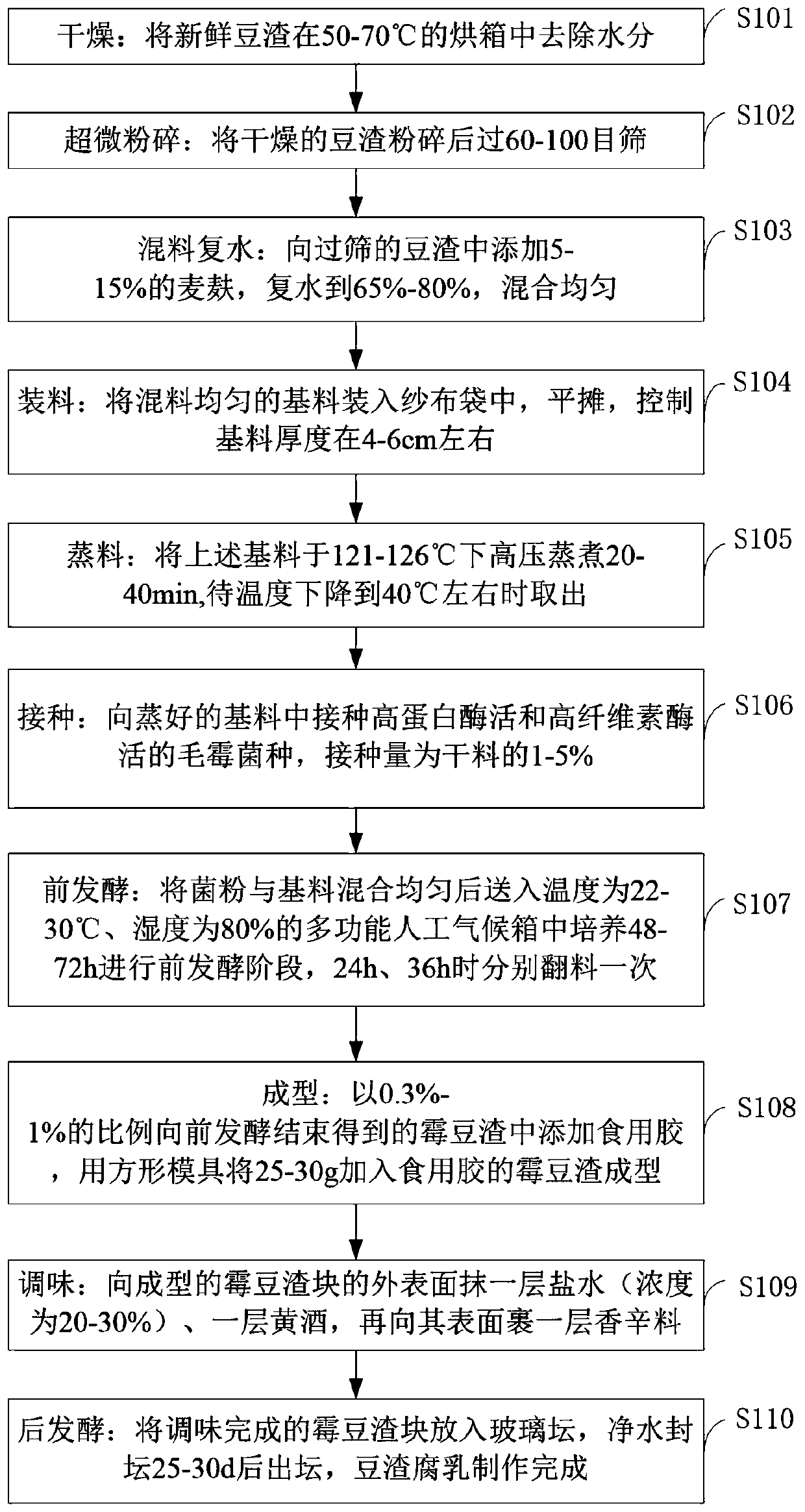

[0069] The method for preparing fermented bean curd with soybean dregs provided by the embodiments of the present invention specifically includes the following steps:

[0070] (1) Drying: remove moisture from fresh bean dregs in an oven at 50°C;

[0071] (2) Superfine grinding: after the dried bean dregs are pulverized, pass through a 70-mesh sieve;

[0072] (3) Mixing and rehydration: add 5% wheat bran to 20 jin of sieved bean dregs, rehydrate to 65%, and mix evenly;

[0073] (4) charging: the base material that mixes evenly is packed in the gauze bag, spread out, control base material thickness at 4cm;

[0074] (5) Steaming: Cook the above-mentioned base material under high pressure at 121°C for 20 minutes, and take it out when the temperature drops to about 40°C;

[0075] (6) inoculation: inoculate 2% mucormycetes of dry material in the base material that cooking is completed and cooled, mix evenly;

[0076] (7) Pre-fermentation: the base material after the inoculation i...

Embodiment 2

[0082] The method for preparing fermented bean curd with soybean dregs provided by the embodiments of the present invention specifically includes the following steps:

[0083] (1) Drying: remove moisture from fresh bean dregs in an oven at 65°C;

[0084] (2) Superfine grinding: after the dried bean dregs are pulverized, pass through a 100-mesh sieve;

[0085] (3) Mixing and rehydration: add 10% wheat bran to 30 catties of sieved bean dregs, rehydrate to 70%, and mix evenly;

[0086] (4) charging: the base material that mixes evenly is packed in the gauze bag, spread out, control base material thickness at 5cm;

[0087] (5) Steaming: Cook the above-mentioned base material under high pressure at 121°C for 30 minutes, and take it out when the temperature drops to about 40°C;

[0088] (6) inoculation: inoculate 5% mucormycetes of dry material in steamed base material, mix evenly;

[0089] (7) Pre-fermentation: sending the base material after inoculation into a multi-functional ...

Embodiment 3

[0096] The method for preparing fermented bean curd with soybean dregs provided by the embodiments of the present invention specifically includes the following steps:

[0097] (1) Drying: remove moisture from fresh bean dregs in an oven at 75°C;

[0098] (2) Superfine grinding: after the dried bean dregs are pulverized, pass through an 80-mesh sieve;

[0099] (3) Mixing and rehydration: add 10% wheat bran to 50 jin of sieved bean dregs, rehydrate to 75%, and mix evenly;

[0100] (4) charging: the base material that mixes evenly is packed in the gauze bag, spread out, control base material thickness at 5cm;

[0101] (5) Steaming: Cook the above-mentioned base material under high pressure at 121°C for 40 minutes, and take it out when the temperature drops to about 40°C;

[0102] (6) inoculation: inoculate 5% mucormycetes of dry material in the base material that cooking is finished, mix homogeneously;

[0103] (7) Pre-fermentation: sending the inoculated base material into a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com