Throughput flexible intelligent assembly logistics path planning platform

A route planning and logistics technology, applied in the direction of comprehensive factory control, program control, instruments, etc., can solve problems such as being unsuitable for direct simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

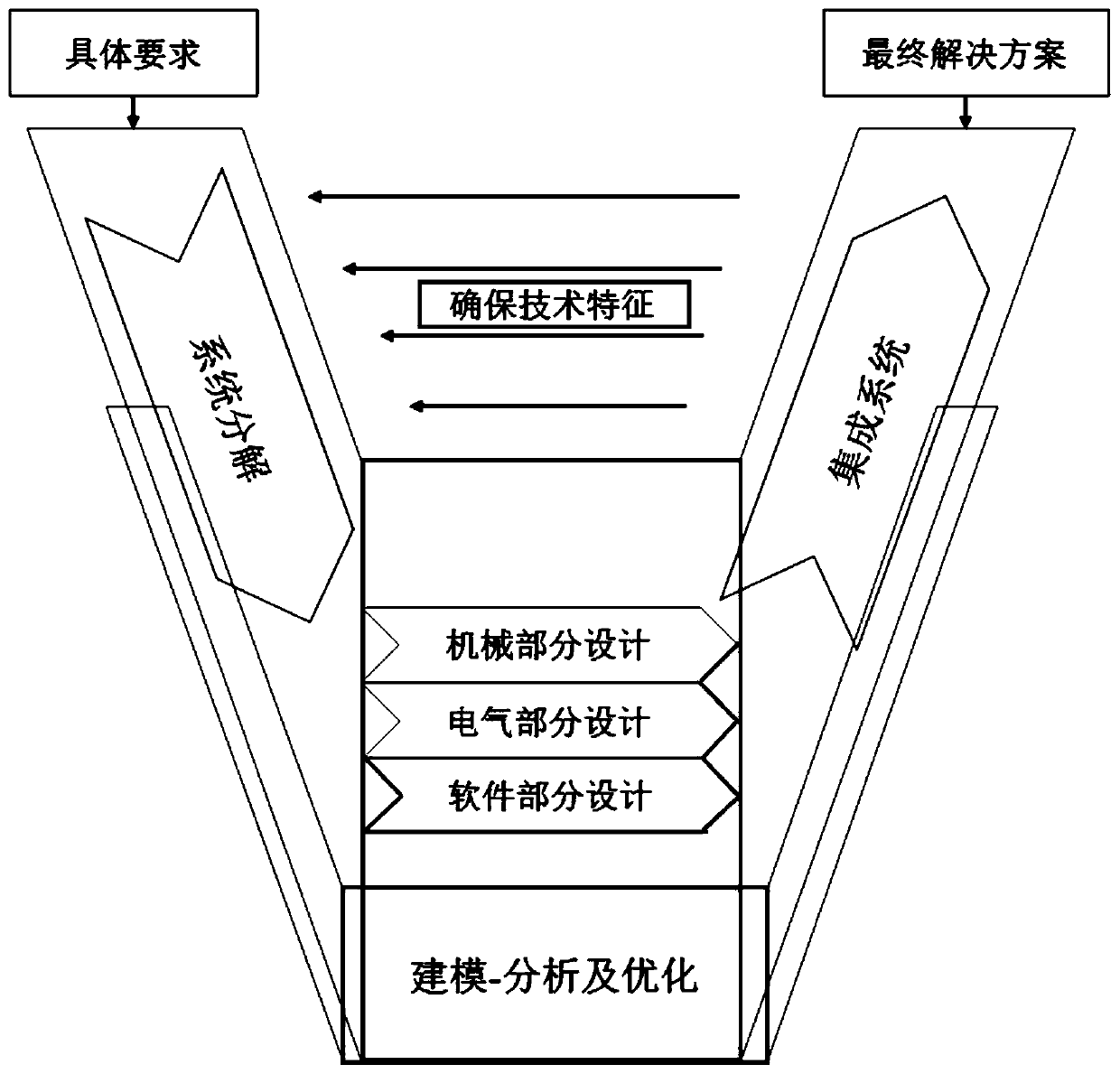

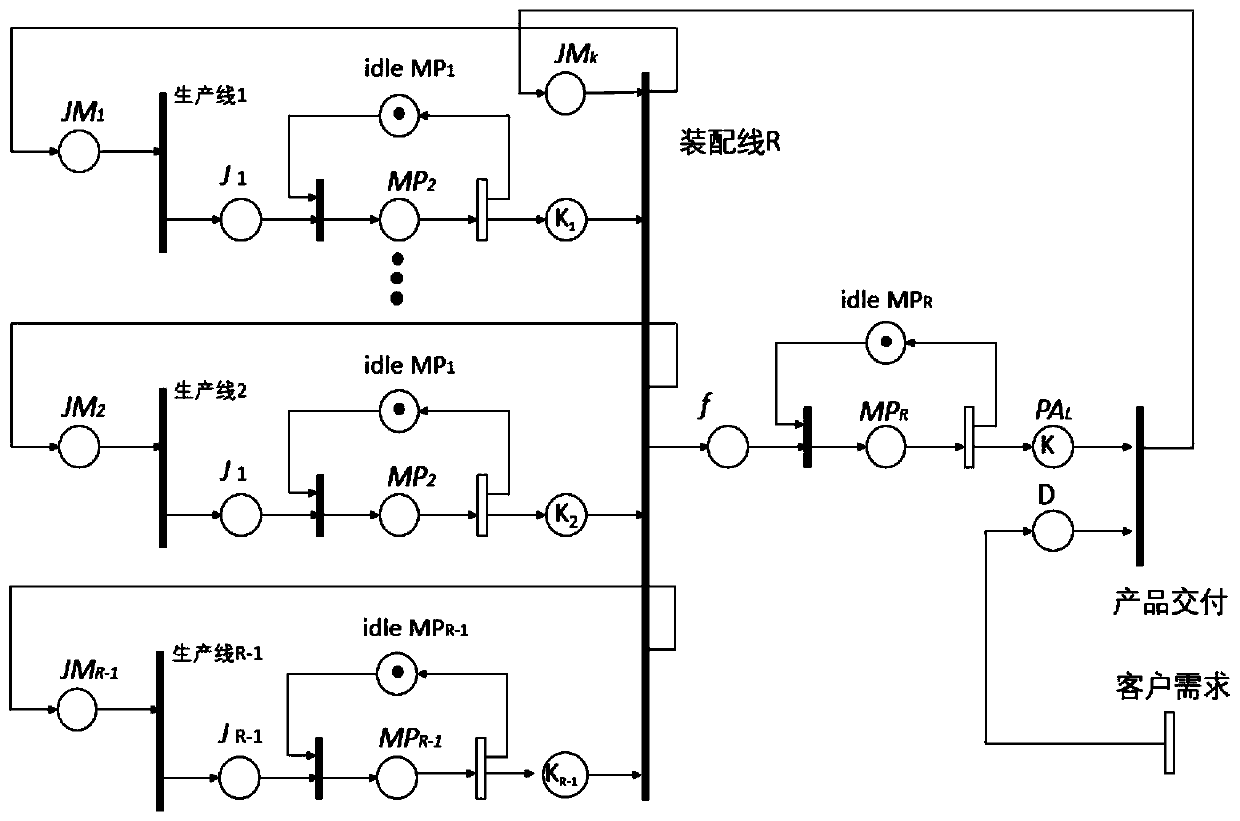

[0087] As shown in all the figures, the present invention relates to an optimal planning method for logistics paths of flexible intelligent assembly. The method relies on planning platforms.

[0088] Under the constraints of the shortest path and the shortest time, the path planning of the present invention combines information such as the priority of use of parts, product assembly time complexity, and parallel evolutionary algorithms to realize dynamic combination path planning and maximize product assembly efficiency and production line equipment utilization efficiency .

[0089] The throughput flexible intelligent assembly logistics path planning platform involved in the present invention includes a sensor system, a production line system, a real-time logistics path intelligent control system, and communication facilities; combined with the enterprise, this time focuses on the simulation model of the automobile braking system as an example and conducts system variables Opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com