A kind of sample preparation method and device for measuring high temperature thermal diffusivity of fiber

A technology for measuring fiber and diffusion coefficient, applied in the direction of measuring device, test sample preparation, sampling, etc., can solve the problem of unclear and difficult fiber axial thermal conductivity, etc., and achieve the effect of ensuring parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The invention discloses a sample preparation method and device for measuring the high-temperature thermal diffusivity of fibers, comprising the following steps:

[0047] a. Measure fiber linear density ρ L ;

[0048] b. Wrap the fiber on the designed winding mold (1) or cut it into small sections to ensure the alignment of the fiber during subsequent filling;

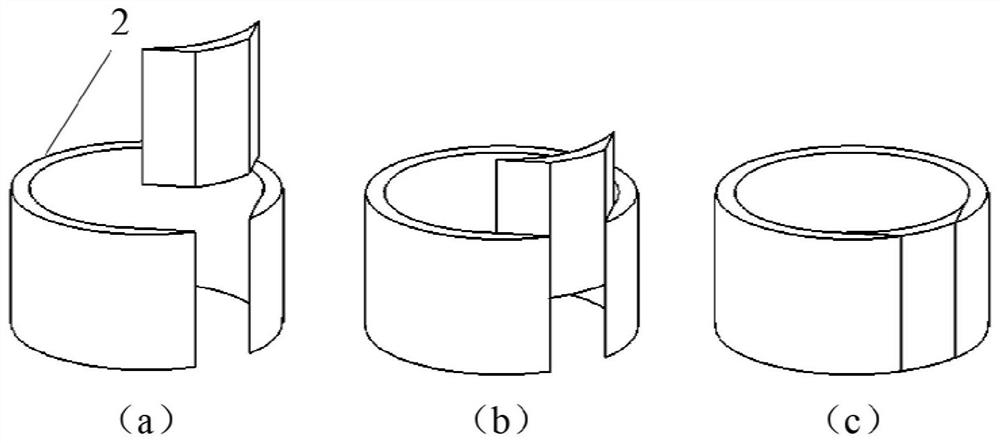

[0049] c. Fill the fibers into a set of steel ring molds (2) designed to withstand high temperatures, so that the interior is filled with fibers;

[0050] d. cut off the fibers between the steel ring molds (2), and polish one side of the fiber-filled steel ring mold (2) with a grinding and polishing machine;

[0051]e. Use the clamp (3) designed to match the outer diameter of the steel ring mold (2) to clamp the steel ring mold (2) to grind the other side flat, and at the same time ensure that the previously polished side remains flat to ensure that the fiber sample (4 ) parallelism;

[0052] f. Measure the t...

Embodiment 1

[0069] The specific steps of the method and device for preparing a pitch-based carbon fiber sample capable of measuring high-temperature thermal diffusivity are as follows:

[0070] a. Accurately measure 3 pieces of pitch-based carbon fiber with a length of 3m with a ruler, and then cut them into 5cm-long sections with a blade. Each piece has a total of 60 pieces. Weigh each piece with an electronic balance and calculate the linear density of each fiber. Take the average value of the linear density ρ of 3 samples as the linear density ρ of the fiber L .

[0071] b. Select 2 high-temperature-resistant steel ring molds, with an inner diameter of 13mm, a height of 8mm, and a wall thickness of 1mm. According to the fiber volume fraction filled in the steel ring mold Calculate the number of fibers n that need to be filled for 65%, n=65%·πR 1 2 ·ρ V / 4ρ L .

[0072] c. Since the pitch-based carbon fiber is a brittle fiber, the winding mold cannot be used, so the fiber is cut...

Embodiment 2

[0080] The difference between the scheme of Example 2 and Example 1 is that the test fiber is T800 grade carbon fiber. The specific steps of the method and device for preparing a T800-grade carbon fiber sample capable of measuring high-temperature thermal diffusivity are as follows:

[0081] a. Use a ruler to accurately measure 3 parts of T800 grade carbon fiber with a length of 3m, and then cut them into 5cm long sections with a blade, each with a total of 60 small sections, weigh each piece with an electronic balance, and calculate the linear density of each fiber . Take the average value of the linear density of 3 samples as the linear density ρ of the fiber L .

[0082] b. Choose 2 high temperature resistant steel ring molds, the inner diameter is 13mm, the height is 3mm, and the wall thickness is 1mm. According to the fiber volume fraction filled in the steel ring mold Calculate the number of fibers n that need to be filled for 65%, n=65%·πR 1 2 ·ρ V / 4ρ L .

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com