Integrated multi-gear automatic transmission of motor and non-bevel-gear differential mechanism

A technology of automatic transmission and differential, which is applied in the direction of differential transmission, vehicle gearbox, gear transmission, etc. The effect of large capacity, shortened shift time and high shift efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

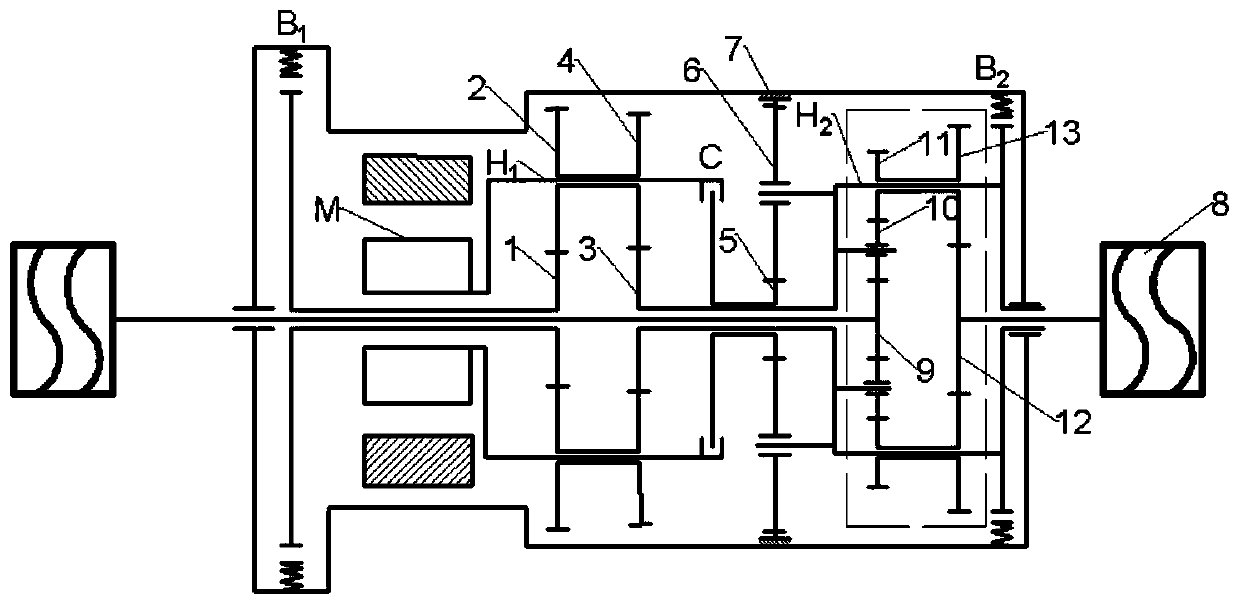

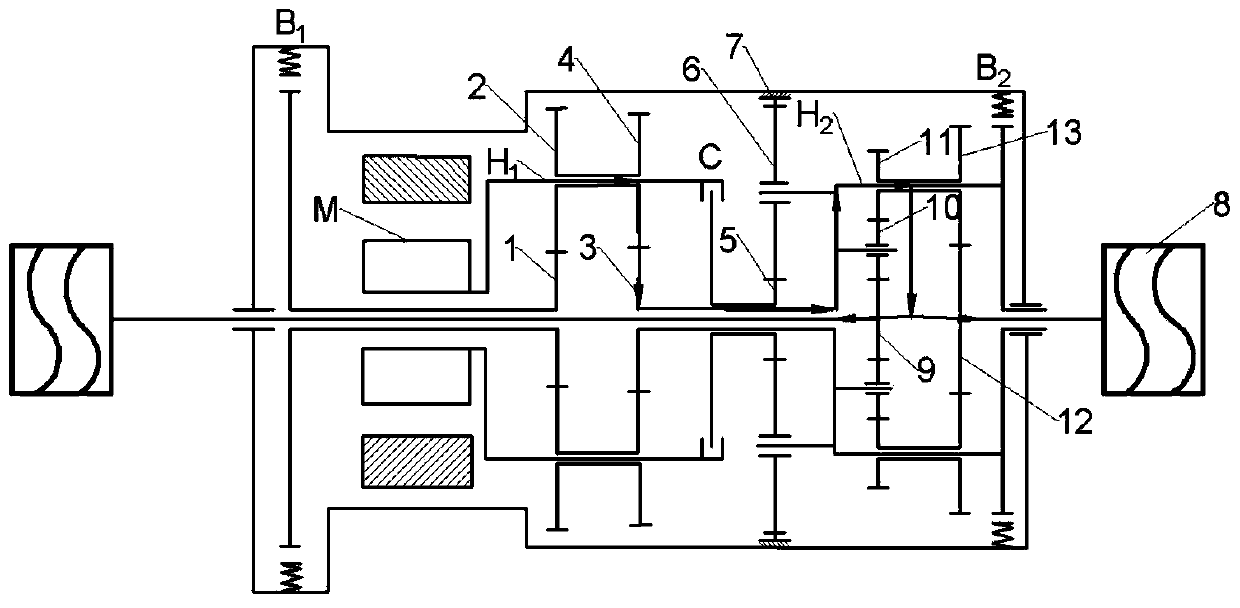

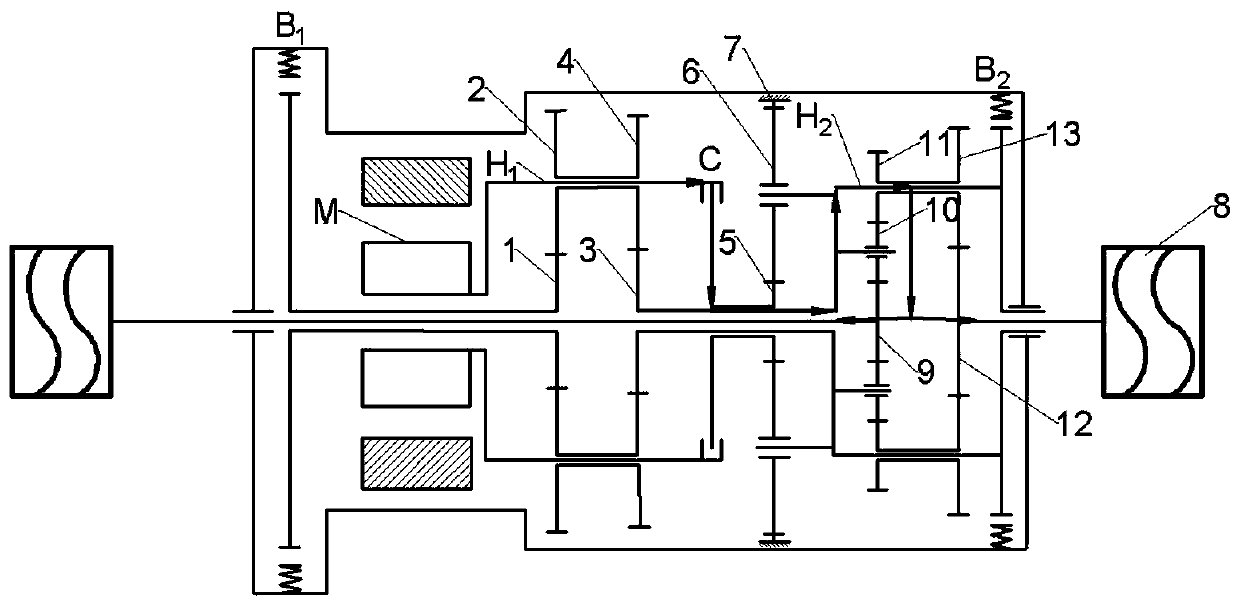

[0022] Such as figure 1 As shown, the present invention relates to a motor-bevelless differential integrated multi-speed automatic transmission, which is characterized by a motor M, a first planetary gear row, a second planetary gear row, and a first brake B 1 , the second brake B 2 , Differential and casing.

[0023] The main shaft of the motor M is fixedly connected with the first planet carrier H1 through a key, and the motor M is installed inside; the first central left gear 1 meshes with the first double left gear 2, and the first central right gear 3 and the first double right gear 4 outside Engagement, second planet carrier H 2 Right end with second brake B 2 Connected, the left end forms a rotation pair with the second planetary gear 6, the second planetary gear 6 is internally meshed with the second sun gear 7, the first planetary carrier H 1 It is connected with the second center wheel 5 with a clutch C, the third center left gear 9 is externally meshed with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com