Novel reinforcing method of fabricated masonry arch body

A prefabricated and masonry technology, which is applied in bridge reinforcement, erection/assembly of bridges, bridge maintenance, etc., can solve the problems of reduced bearing capacity, safety accidents, durability, strength and other mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described below in conjunction with specific embodiments.

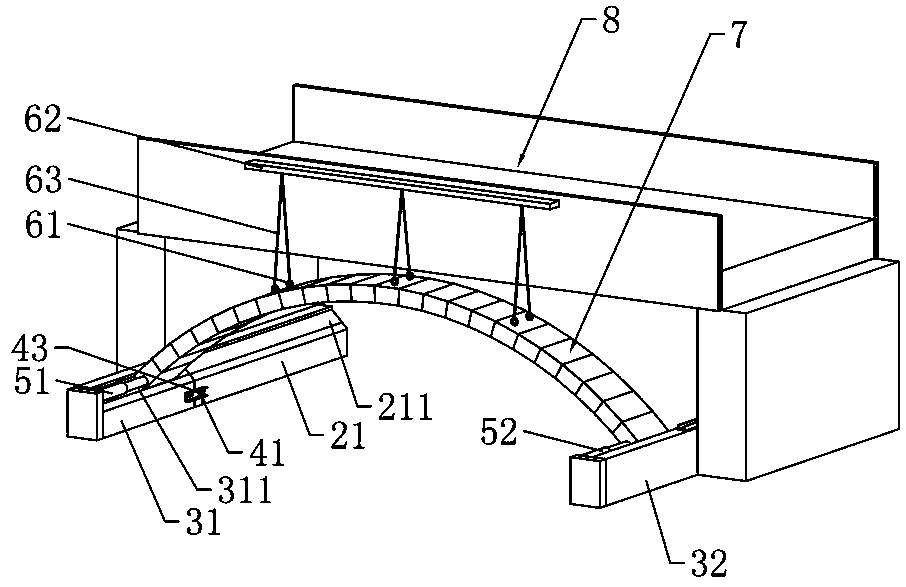

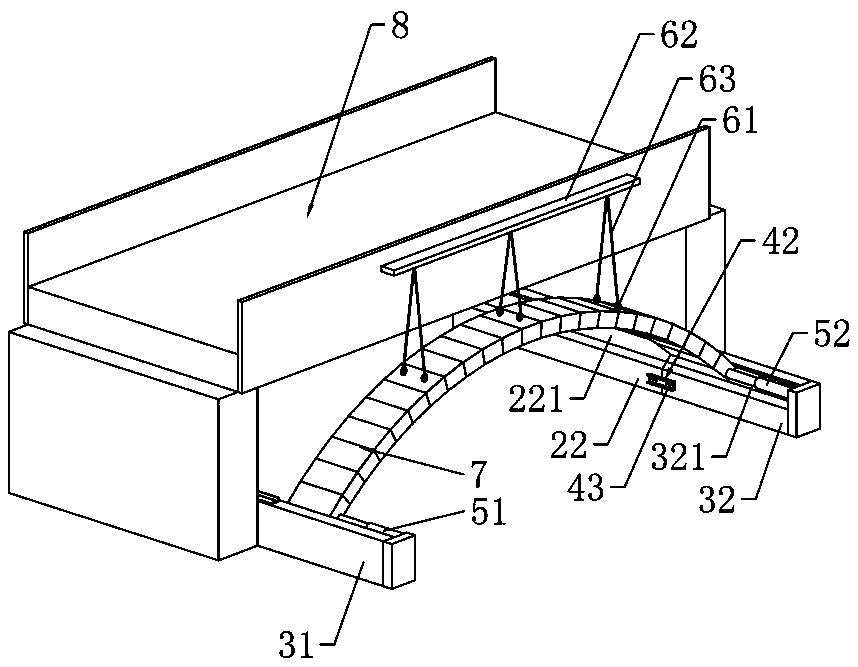

[0052] Such as Figure 1 to Figure 4 Shown, a kind of reinforcement method of new type prefabricated masonry arch body, it comprises the following steps, specifically:

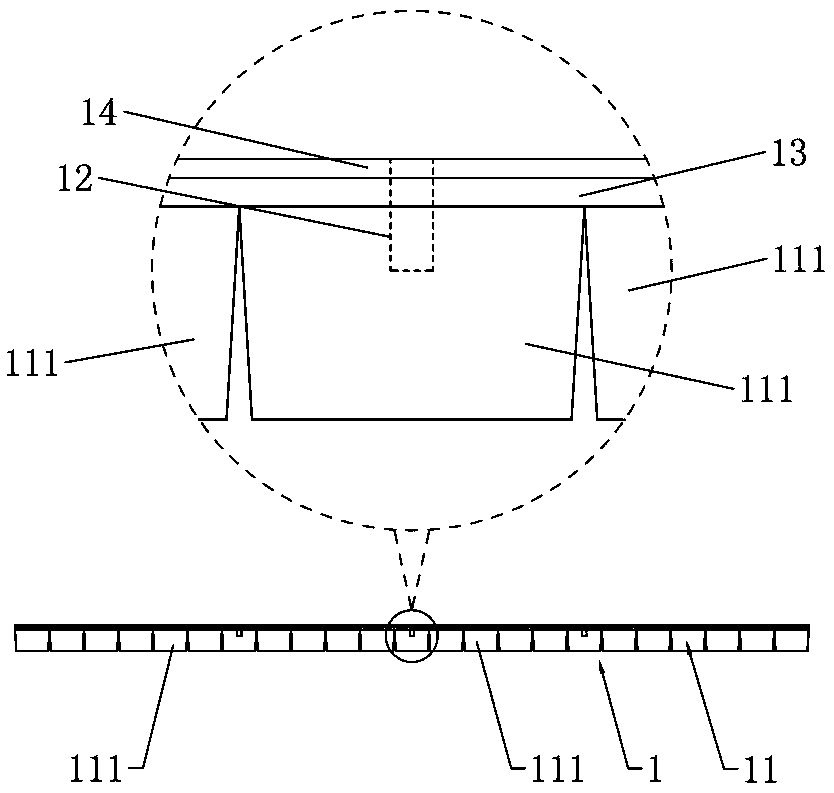

[0053] a. Prefabricated concrete arch block 111, the concrete arch block 111 is formed by pouring concrete, the longitudinal section of the concrete arch block 111 is in the shape of an isosceles trapezoid and the width value of the upper end of the concrete arch block 111 is larger than the width value of the lower end;

[0054] b. Arrange the prefabricated concrete arch blocks 111 neatly along a straight line according to the required length, and there is a gap between two adjacent concrete arch blocks 111 to form a linear array of arch blocks 11; for placing in the lifting position For concrete arch blocks 111, metal threaded casings 12 are pre-embedded inside, and the upper ends of metal threaded casings 12 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com