Zinc oxide yarn, preparation method thereof and application of yarn

A zinc oxide, yarn technology, applied in the direction of yarn, rayon manufacturing, fiber chemical characteristics, etc., can solve the problems of increasing the cost of product production and use, high cost of metallic silver or its oxide, and low stability of silver ions. , to achieve the effect of promoting development, improving use safety, and ensuring bacteriostatic effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

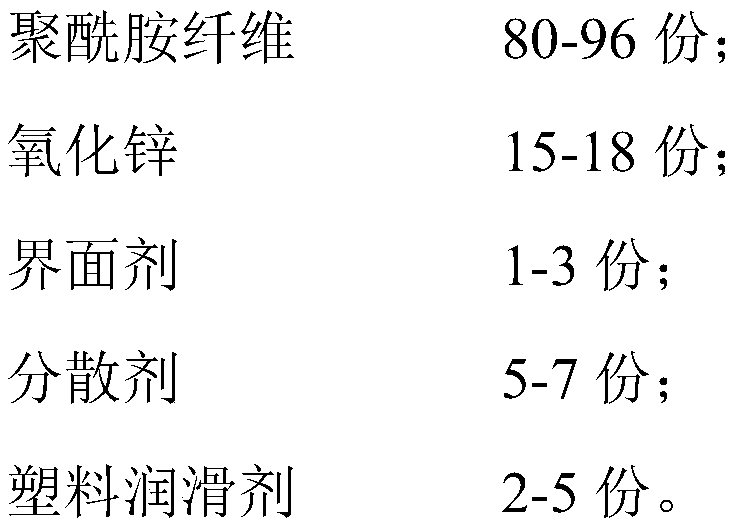

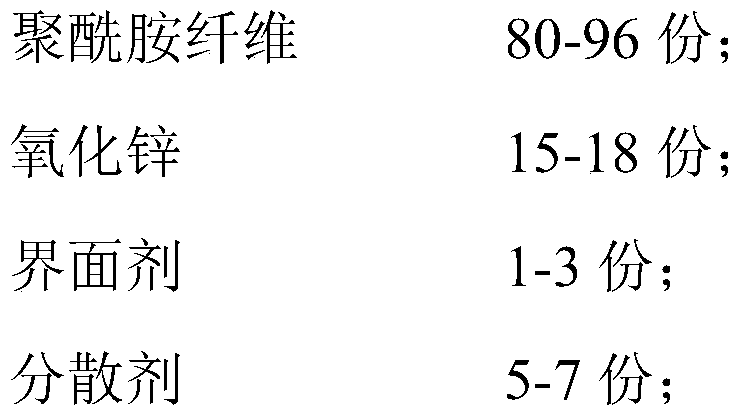

[0045] A zinc oxide yarn, its components include polyamide fiber, zinc oxide, interface agent, dispersant and plastic lubricant.

Embodiment 2

[0047] A production method of zinc oxide yarn, comprising the following steps:

[0048] (1) preliminary cleaning is carried out to zinc oxide by ethanol;

[0049] The concrete process of described preliminary cleaning is:

[0050] (11) Zinc oxide is contained in the container, and ethanol is added in the container until the 10-15cm of the upper surface of the zinc peroxide is submerged in the ethanol liquid level;

[0051] (12) Stir the zinc oxide and ethanol in the container, the stirring speed is 30r / min, and the stirring time is 5min;

[0052] (13) After the stirring is completed, the ethanol suspension of zinc oxide is left to stand in the container for 30min, so that the zinc oxide sinks;

[0053] (14) The supernatant is discharged, and the spacing between the upper surface of ethanol after the supernatant is discharged and the zinc oxide upper surface after precipitation is guaranteed to be 2-4cm;

[0054] (15) Steps (12)-(14) are repeated for 3-5 times, thus completi...

Embodiment 3

[0085] The difference between the present embodiment and embodiment 1 is that the components and parts thereof mixed in the step (6) are:

[0086]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com