High-alloy tool steel plate and production method thereof

A production method and technology for steel plates, applied in the field of metallurgy, can solve the problems of domestic die-casting enterprises struggling, difficult to break through in quality, serious trade deficit, etc., and achieve the effects of good processing performance, excellent die-casting performance, and improved impact toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The thickness of the 1.2711 high-alloy tool steel plate in this embodiment is 12mm, and its chemical composition and mass percentage are shown in Table 1.

[0026] The production method of the 1.2711 high-alloy tool steel plate of this embodiment comprises heating, rolling, and heat treatment processes, and the specific process steps are as follows:

[0027] (1) Heating process: the billet is put into the soaking pit, and the temperature of the soaking pit is 520°C; the heating rate of the billet is 50°C / h, when the temperature is raised to 1000°C, it is kept for 10 hours, and then the temperature is raised to 1280°C, and then kept for 36 hours;

[0028] (2) Rolling process: hot rolling mode is used for production, the starting rolling temperature is 980°C, the final rolling temperature is 850°C, and no water is applied after rolling;

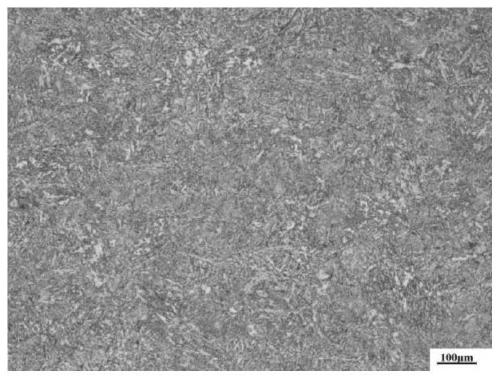

[0029] (3) Heat treatment process: heat treatment by quenching + tempering, steel plate quenching temperature 980 ° C, heat preservatio...

Embodiment 2

[0032] The thickness of the 1.2711 high-alloy tool steel plate in this embodiment is 18 mm, and its chemical composition and mass percentage are shown in Table 1.

[0033] The production method of the 1.2711 high-alloy tool steel plate of this embodiment comprises heating, rolling, and heat treatment processes, and the specific process steps are as follows:

[0034] (1) Heating process: the billet is put into the soaking pit, and the temperature of the soaking pit is 540°C; the heating rate of the billet is 60°C / h, when the temperature is raised to 1000°C, it is kept for 12 hours, and then the temperature is raised to 1300°C, and then kept for 38 hours;

[0035] (2) Rolling process: hot rolling mode is used for production, the starting rolling temperature is 970°C, the final rolling temperature is 830°C, and no water is applied after rolling;

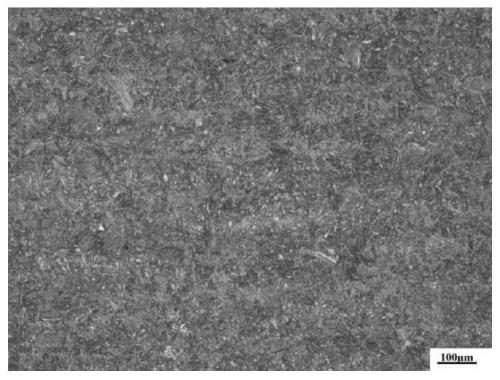

[0036] (3) Heat treatment process: heat treatment by quenching + tempering, steel plate quenching temperature 1000 ° C, heat preservat...

Embodiment 3

[0039] In this embodiment, the thickness of 1.2711 high-alloy tool steel plate is 25 mm, and its chemical composition and mass percentage are shown in Table 1.

[0040] The production method of the 1.2711 high-alloy tool steel plate of this embodiment comprises heating, rolling, and heat treatment processes, and the specific process steps are as follows:

[0041] (1) Heating process: the billet is put into the soaking pit, and the temperature of the soaking pit is 570°C; the heating rate of the billet is 75°C / h, when the temperature rises to 1000°C, it is kept for 15 hours, and then the temperature is raised to 1320°C, and then kept for 39 hours;

[0042] (2) Rolling process: hot rolling mode is used for production, the starting rolling temperature is 980°C, the final rolling temperature is 825°C, and there is no watering after rolling;

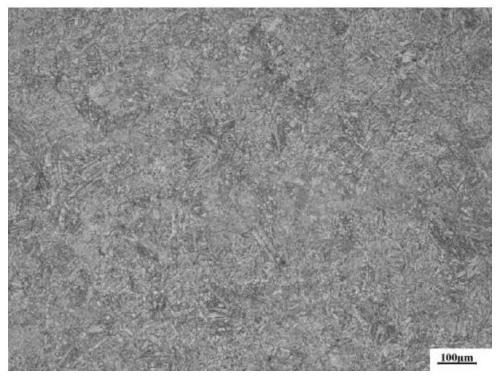

[0043] (3) Heat treatment process: heat treatment by quenching + tempering, steel plate quenching temperature 1020 ° C, heat preservation co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com