Method for preparing high-purity spherical instant boric acid by induction of organic molecules

A technology of organic molecules and boric acid, applied in chemical instruments and methods, inorganic chemistry, boron compounds, etc., can solve the problems of easy agglomeration and slow dissolution rate of boric acid, and achieve fluidity without agglomeration, low cost and good fluidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

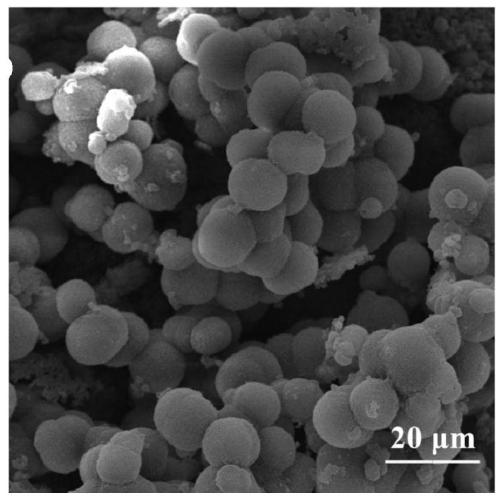

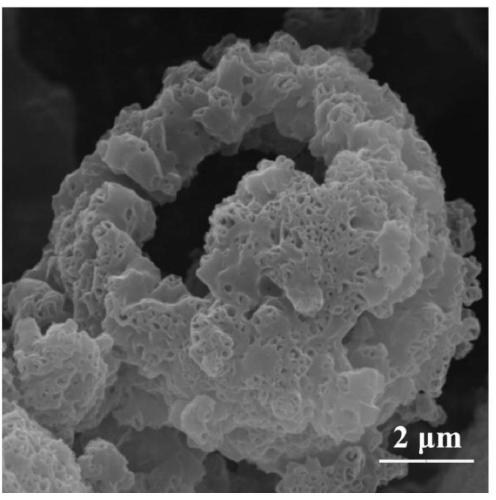

[0025] Add 20g of analytically pure boric acid into a pressure vessel containing 100g of a mixed solvent, wherein the mixed solvent is prepared from ethanol, acetone and water according to the above formula ratio; heat the pressure vessel to make the temperature reach about 140°C to obtain a clear solution; then control the cooling rate for about 5 °C / min, lower the temperature of the container to room temperature, and place it at room temperature for about 0.5 hours. At this time, a large amount of white precipitate precipitates in the solution; filter the precipitate and dry it at 60 °C to obtain loose spherical porous boric acid powder , whose shape is shown in Figure 1. The X-ray diffraction pattern of the obtained powder is shown in figure 2 After analysis, it meets the standard card JCPDS No.30-0199; take 3.0g of the obtained spherical boric acid, add it to a beaker filled with 97g of deionized water, and magnetically stir at 400rpm, and it can be completely dissolved wi...

Embodiment 2

[0028] With the difference condition of embodiment 1: (1) used mixed solvent is the mixed solution of acetone and water;

[0029] (2) The temperature of the pressure vessel is 300°C;

[0030] (3) The cooling rate is about 20°C / min;

[0031] (4) The drying temperature is 80°C.

Embodiment 3

[0033] Distinguishing conditions with Example 1: (1) the mixed solvent used is the mixed solution of ether and water;

[0034] (2) The temperature of the pressure vessel is 40°C;

[0035] (3) The cooling rate is about 0.2°C / min;

[0036] (4) The drying temperature is 110°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com