System and method for extracting and recovering fine coal slime from coal slime

A coal slime and clean coal technology, applied in chemical instruments and methods, wet separation, selective deposition methods, etc., can solve the problems of vegetation damage at the discharge site, surrounding air pollution, and hidden dangers of environmental protection, so as to reduce waste of resources, Efficient purification and recovery, and the effect of reducing the amount of discharged coal slime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

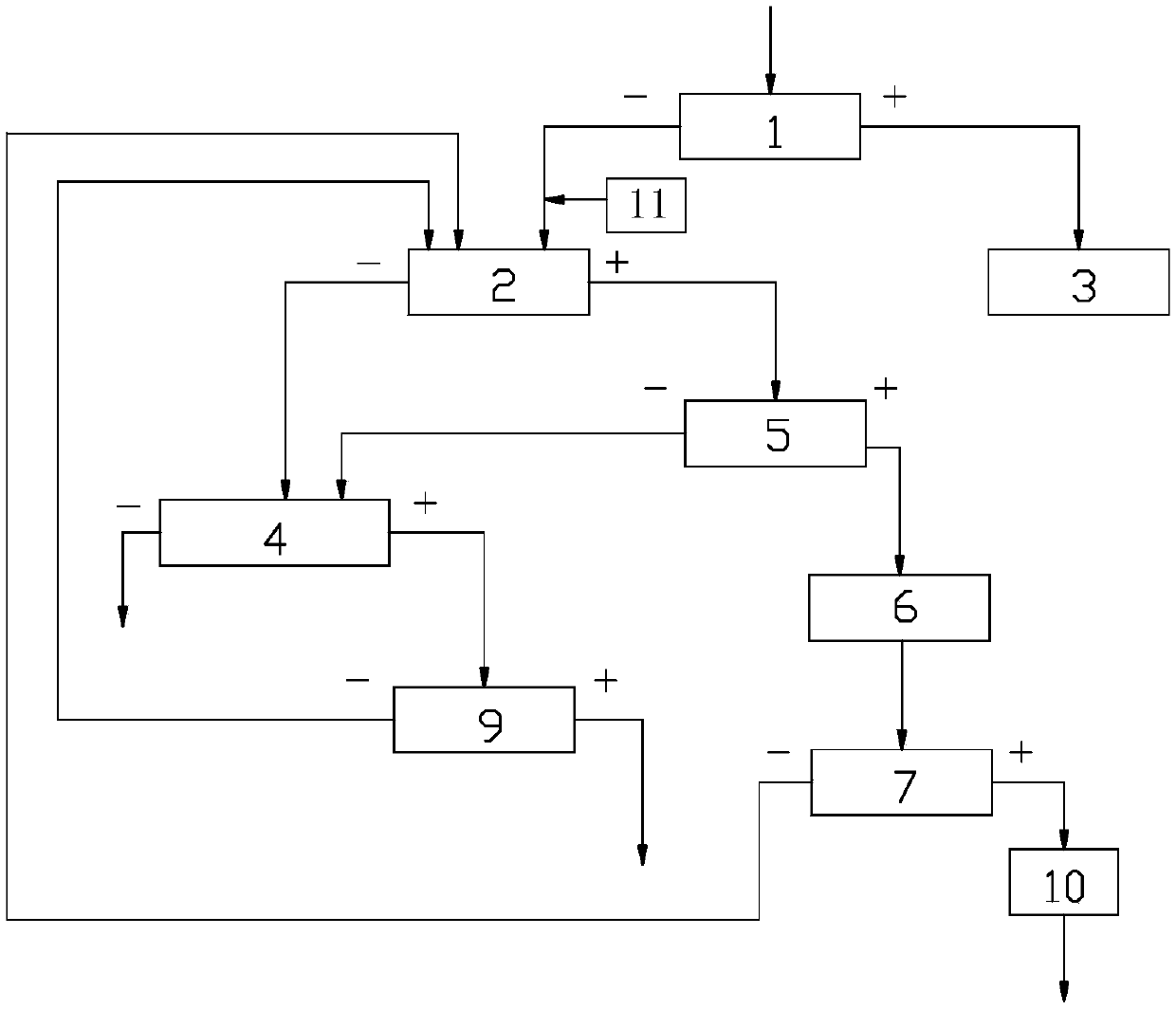

[0046] Such as figure 1 As shown, a system for purifying and recovering fine coal slime from coal slime, which includes a classifying cyclone 1, a first-stage thickener 2, a coarse coal slime separation system 3, a second-stage thickener 4, a laminated screen 5, and a plate Press into the material barrel 6, the first plate and frame filter press 7, the second plate and frame filter press 9, the drying device 10, the flocculant dosing device 11, the system slime water is classified by the classifying cyclone 1, and the classifying cyclone The overflow port of 1 is connected to the feed port of the first-stage thickener 2 through pipelines, and the graded overflow enters the first-stage thickener 2, and the underflow port of the graded cyclone 1 is connected with the feed port of the coarse slime separation system 3 through the pipe. The bottom flow of the classification enters the coarse coal slime separation system 3, the overflow port of the first-stage thickener 2 is connect...

Embodiment 2

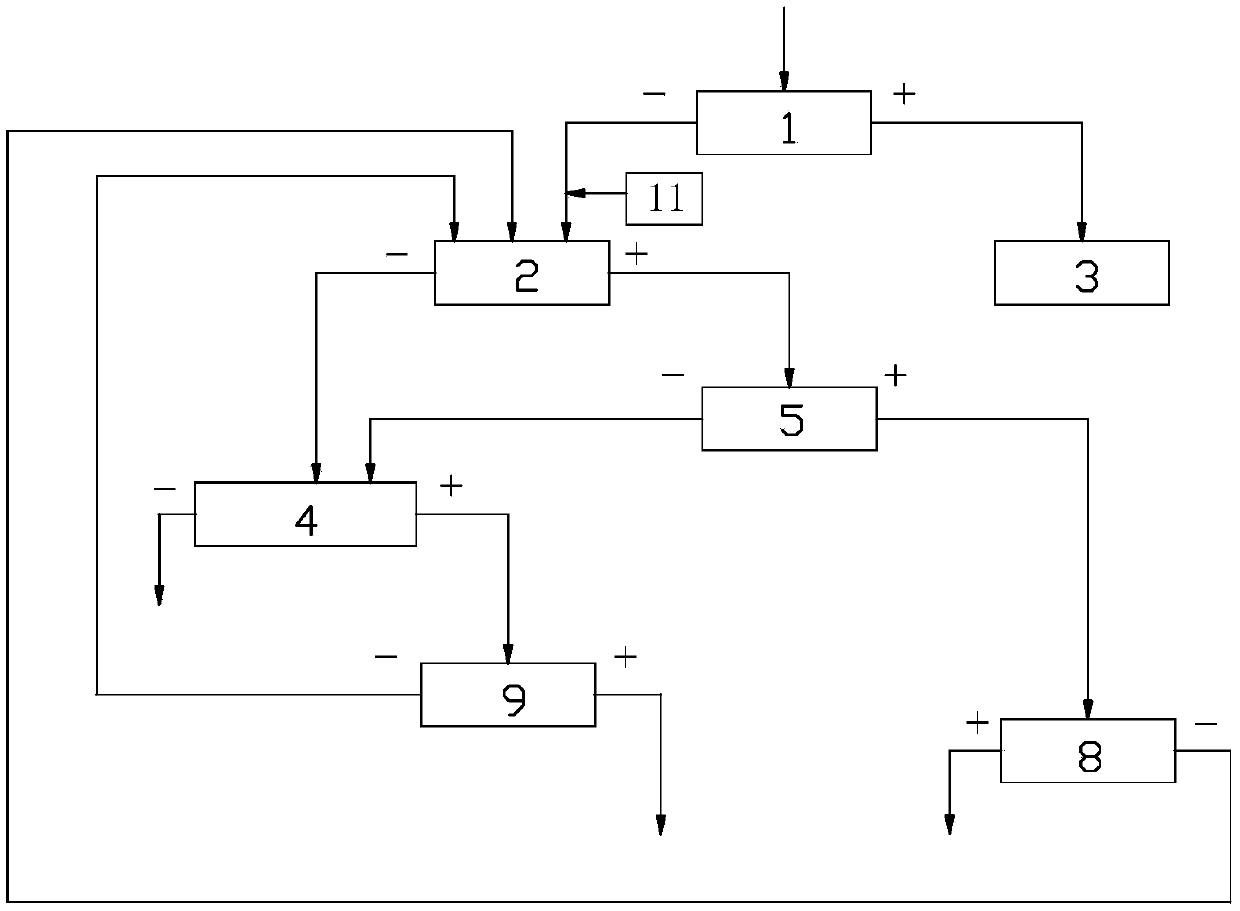

[0050] Such as figure 2 As shown, a system for purifying and recovering fine coal slime from coal slime, which includes a classifying cyclone 1, a first-stage thickener 2, a coarse coal slime separation system 3, a second-stage thickener 4, a laminated screen 5, a settling type centrifuge 8, the second plate and frame filter press 9, flocculant dosing device 11, the system slime water is graded by classifying cyclone 1, the overflow port of classifying cyclone 1 is connected with the feed port of first stage thickener 2 Through the pipeline connection, the graded overflow enters the first-stage thickener 2, the underflow port of the graded cyclone 1 is connected with the feed port of the coarse slime separation system 3 through pipelines, and the graded bottom flow enters the coarse coal slime separation system 3, The overflow port of the first-stage thickener 2 is connected to the feed port of the second-stage thickener 4 through pipelines, and the coal slime in the first-st...

Embodiment 3

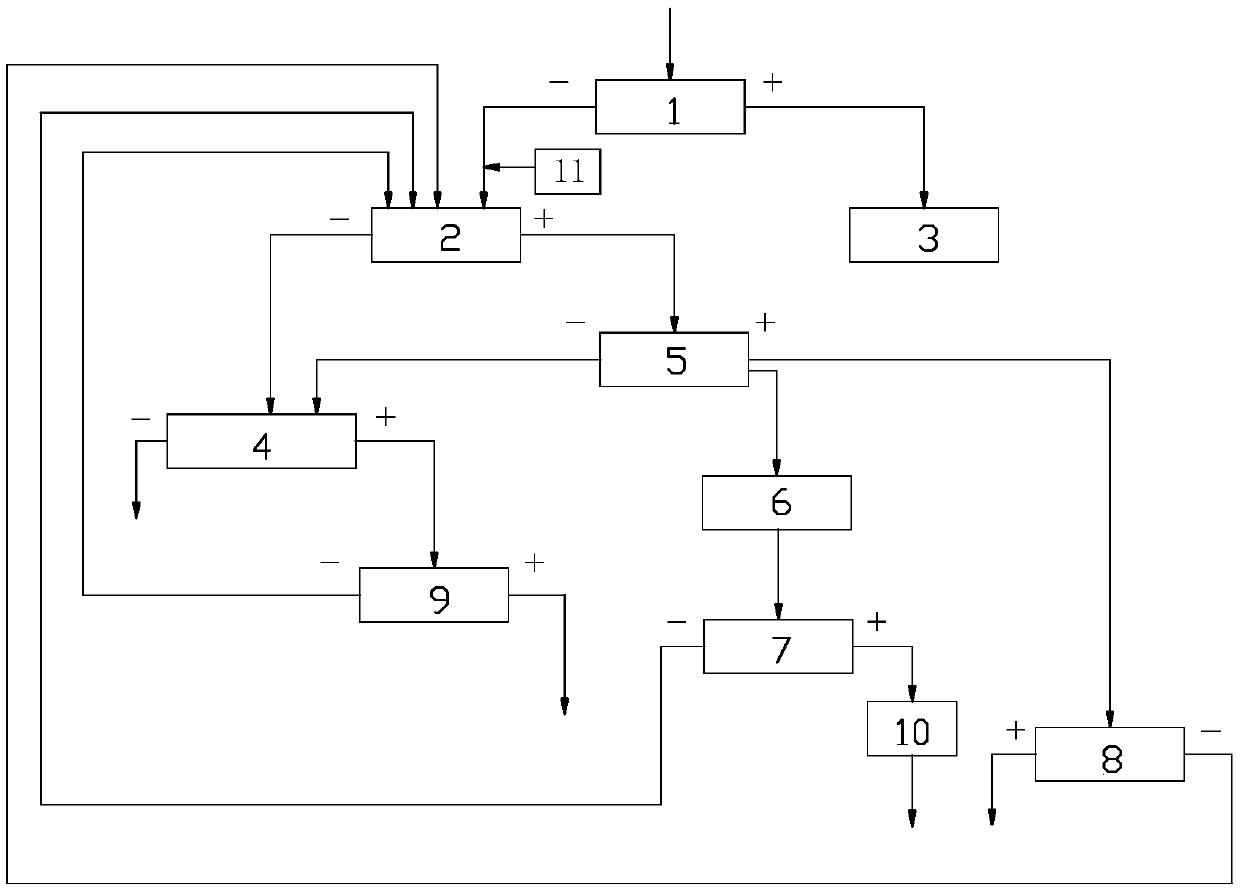

[0054] Such as image 3 As shown, a system for purifying and recovering fine coal slime from coal slime, which includes a classifying cyclone 1, a first-stage thickener 2, a coarse coal slime separation system 3, a second-stage thickener 4, a laminated screen 5, and a plate Press into material barrel 6, first plate and frame filter press 7, decanter centrifuge 8, second plate and frame filter press 9, drying device 10, flocculant dosing device 11, system slime water passes through classifying cyclone 1 Classification, the overflow port of the classifying cyclone 1 is connected with the feed port of the first-stage thickener 2 through pipelines, and the classified overflow enters the first-stage thickener 2, and the underflow port of the classifying cyclone 1 is connected with the coarse coal slime separation system 3 The feed inlet of the first stage thickener is connected with the pipeline, and the graded underflow enters the coarse coal slime separation system 3. The overflo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com