T-beam concrete mix proportion method based on orthogonal design and normal cloud model machine-made sand

A technology of orthogonal design and mix ratio, which is applied in the field of design and optimization of concrete mix ratio of machine-made sand T beams, can solve the problems of long design cycle, single performance, and a lot of time, and achieve cost saving, time saving, and speeding up the construction progress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

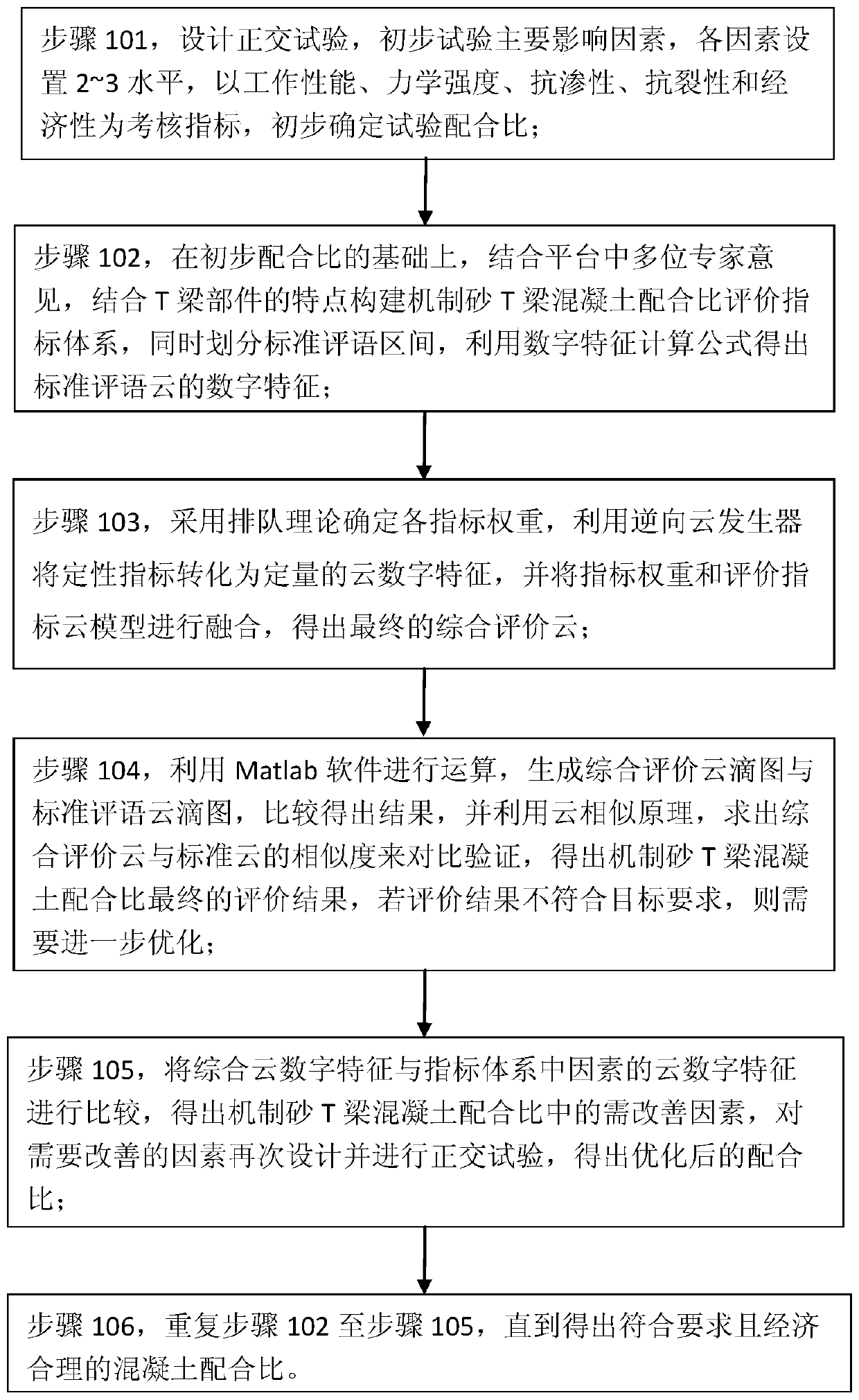

Method used

Image

Examples

Embodiment 1

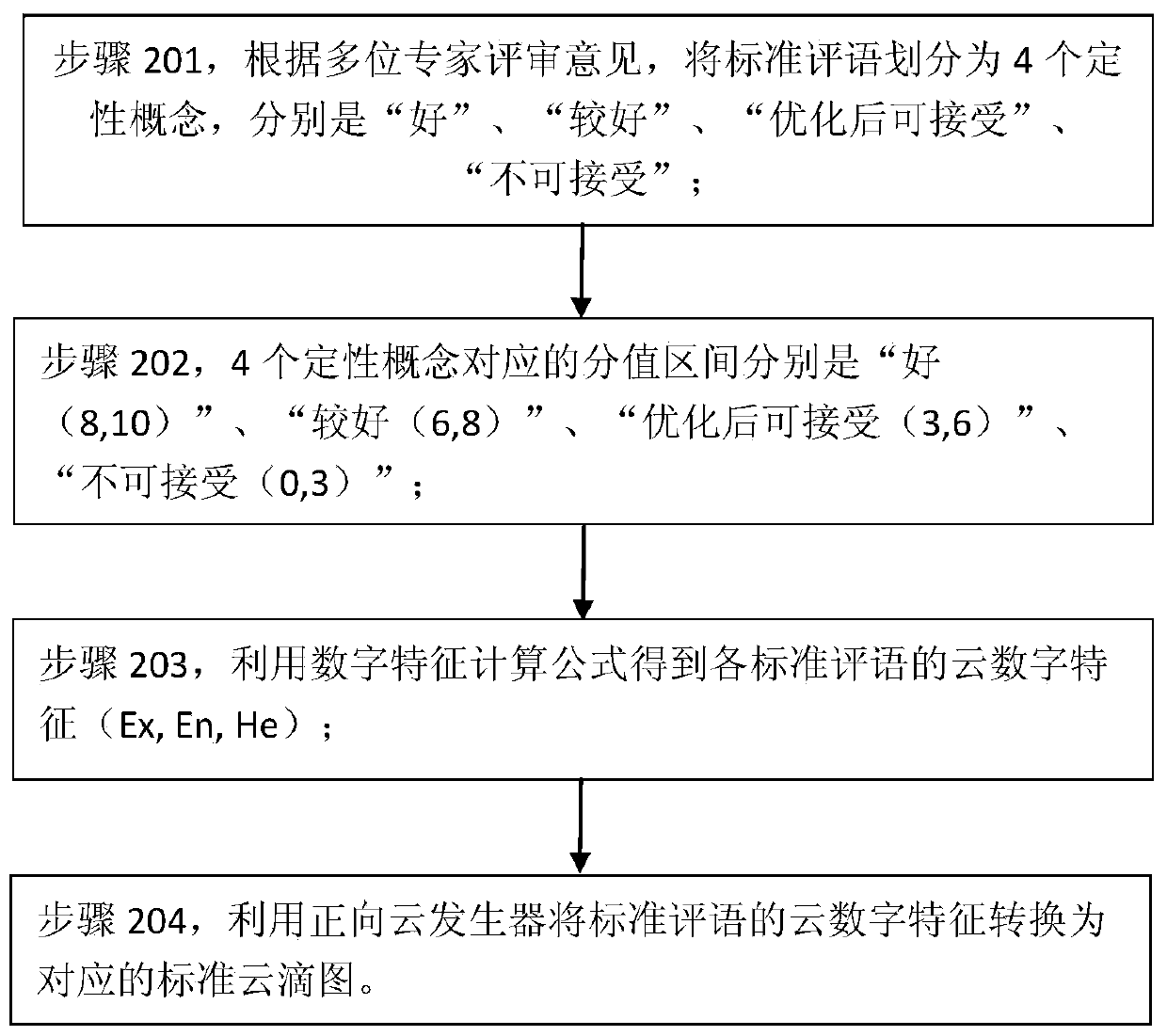

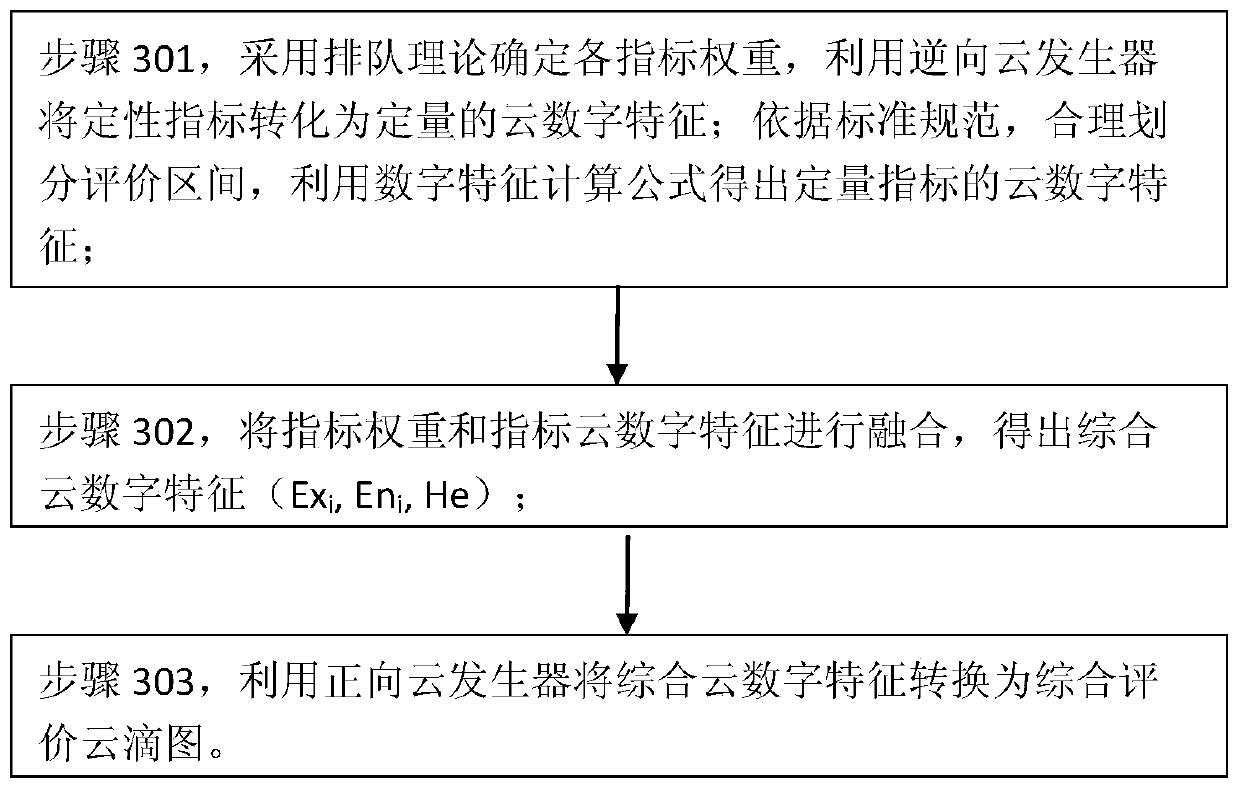

[0041] This embodiment provides a new design method of concrete mix ratio, combining the orthogonal design idea and normal cloud model method, this method is based on the traditional fuzzy set theory and the theoretical model of probability theory, and the concrete mix ratio design The hierarchical state of the class parameter index is converted into the corresponding cloud digital feature, and the uncertainty conversion between the qualitative concept and its quantitative representation is realized. In the mix ratio design, the control factors in the traditional concrete mix ratio method are expanded, and the mix ratio evaluation system established by expert evaluation is used to determine the mix ratio comment range and standard comment cloud digital characteristics. For a specific mix ratio scheme, the queuing theory is used to determine the important order of the indicators in the mix ratio control factors, and the weights are assigned. The reverse normal cloud generator is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com