Device and method for detecting water content of sand-gravel aggregate

A technology of moisture content and sand and gravel materials, which is applied in the field of sand and gravel aggregate moisture content detection devices, can solve the problems of inaccurate moisture content measurement data, large fluctuations in detected moisture content data, and unguaranteed accuracy, etc., to achieve long-term dynamic correction , Eliminate detection error and data uncertainty, improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The scheme of this application is further described in conjunction with the accompanying drawings as follows:

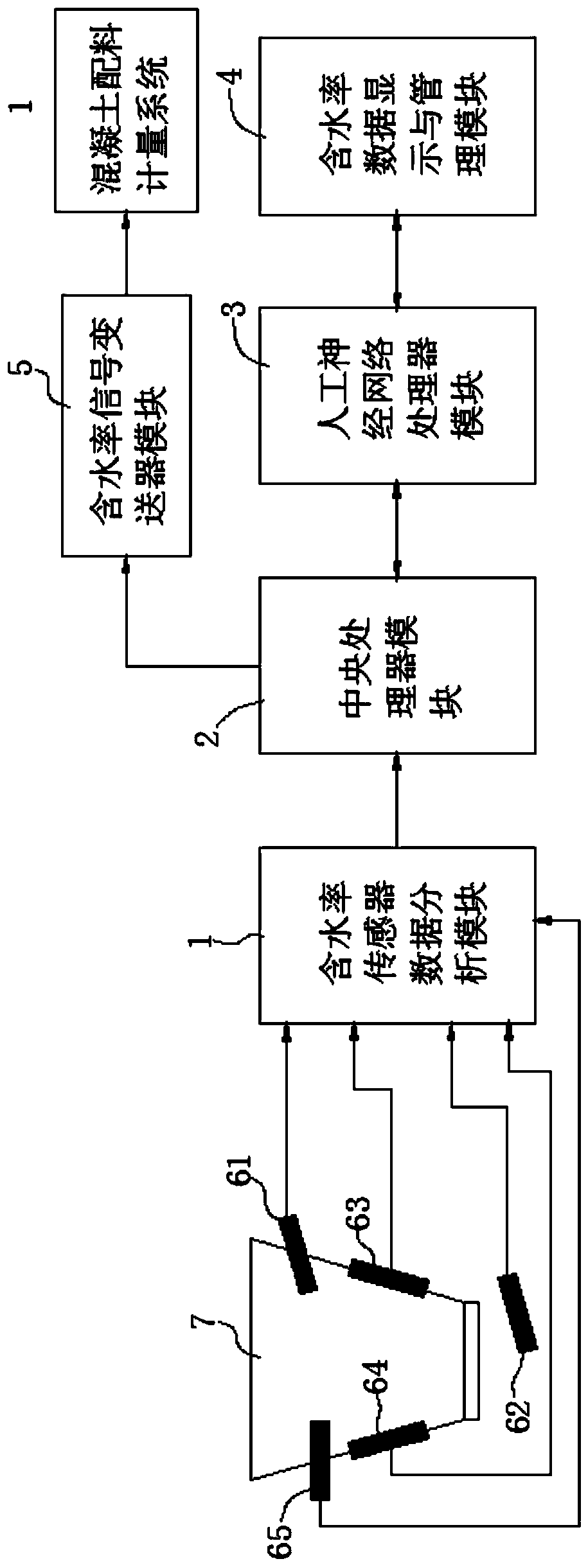

[0017] See attached figure 1 , a sand and gravel aggregate water content detection device, which includes a water content sensor data analysis module 1 connected in sequence, a central processing unit module 2, an artificial neural network processor module 3, a water content data display and management module 4 and a water content rate signal transmitter 5, the water content sensor data analysis module 1 is connected with a plurality of sensors, the sensors include two water content microwave sensors 61,62, two water content capacitance sensors 63,64 and one temperature sensor 65 , the moisture content microwave sensor 61 of one road is inserted in the gravel silo 7, the moisture content microwave sensor 62 of the other road is installed below the discharge port of the sand and gravel silo 7, and the two moisture content capacitive sensors 63, 64 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com