Coal-fired power plant carbon emission on-line monitoring method based on laser induced breakdown spectroscopy

A laser-induced breakdown, coal-fired power plant technology, applied in material excitation analysis and other directions, can solve problems such as high carbon content, lack of coal-fired element analysis data, and inability to meet continuous online measurement, achieving fast analysis speed and high sensitivity , the calculation results are accurate and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

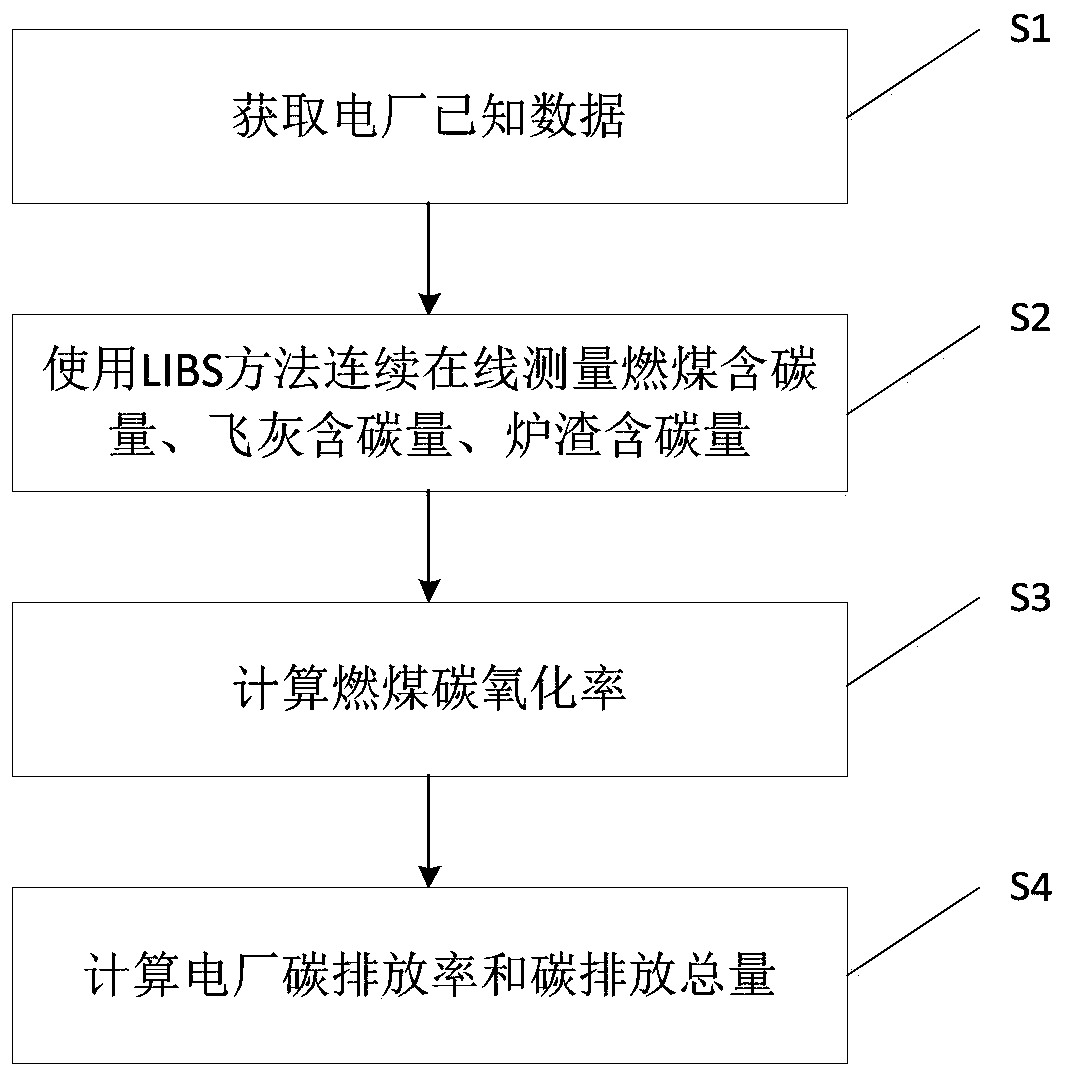

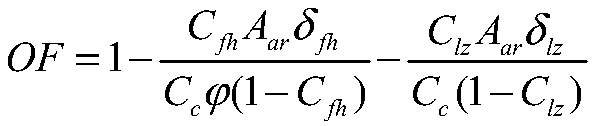

[0038] This method uses the carbon oxidation rate to represent the conversion ratio of C elements in the combustion process. Based on the law of mass conservation, the carbon oxidation rate is calculated by the carbon content of the fuel, the carbon content of the fly ash and the carbon content of the slag, and then calculated by the C of the combustion. emitted CO 2 . During the combustion process, although CO is produced, CO will eventually be oxidized to CO in the environment 2 , this method has taken CO into account.

[0039] Laser-induced breakdown spectroscopy does not need to prepare samples and can analyze inhomogeneous samples. It can directly measure the carbon content of coal, fly ash and slag online in the material flow, which is the basis of the online monitoring of the present invention. .

[0040] The specific implementation steps include:

[0041] S1. Obtain known data from the power plant;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com