Improved kagome micro-truss lattice sandwich structure and calculation method thereof

A sandwich structure and micro-truss technology, applied in calculation, computer-aided design, connecting components, etc., can solve problems such as stress concentration at nodes, achieve the effects of improving bearing capacity, reducing structural quality, and enhancing specific stiffness and specific strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in further detail now in conjunction with accompanying drawing.

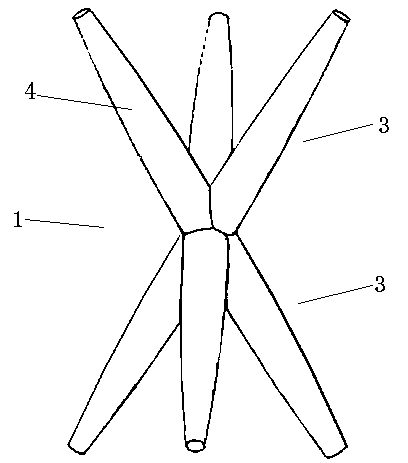

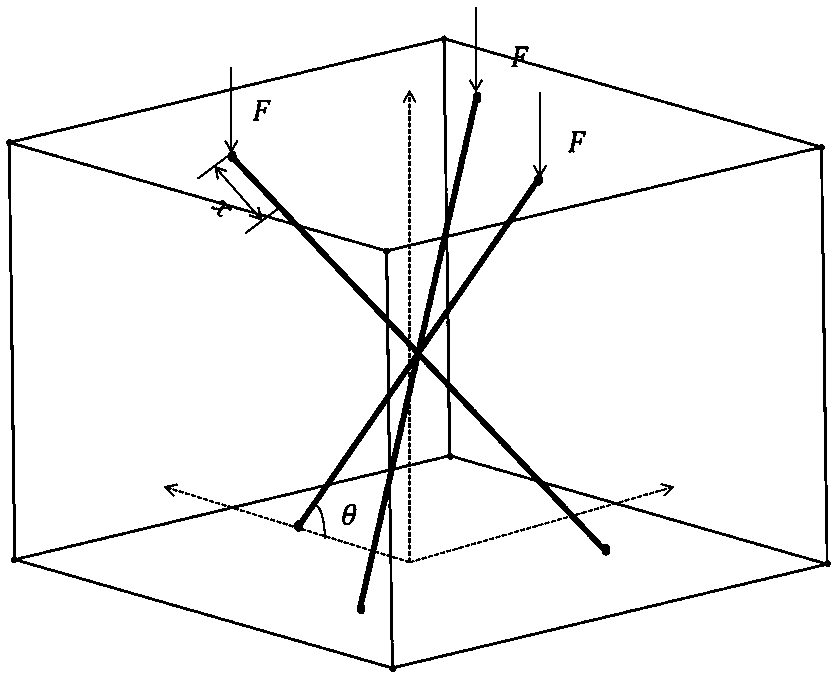

[0030] A single bar can be similarly simplified to a cantilever beam structure when it is stressed, and the stress on the bar is the largest at the central node, and gradually decreases toward the edge. The traditional equal-section rods are prone to damage due to excessive stress at the joints, while the stress at the edges is small, resulting in waste of quality. If the rod diameter of each part can be matched with the stress value of the part, the load-bearing efficiency can be maximized.

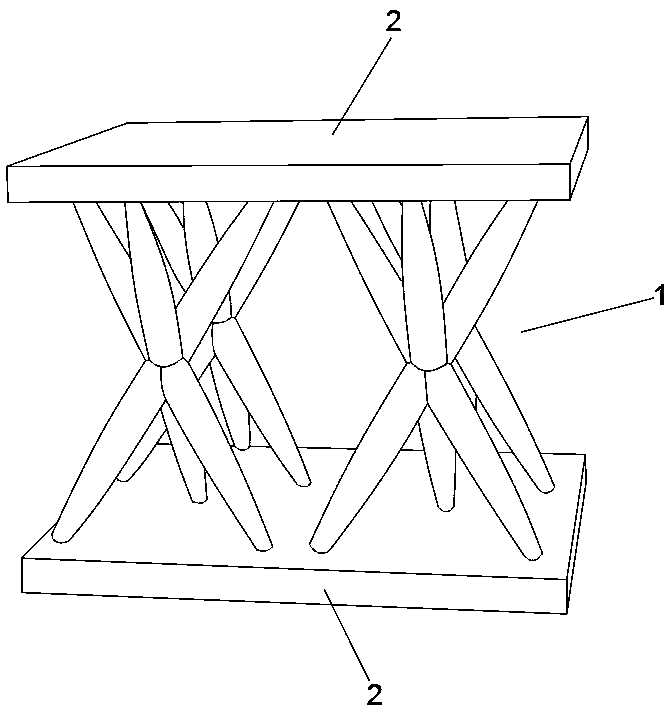

[0031] Specifically, combine figure 1 , figure 2 An improved kagome micro-truss lattice sandwich structure is shown, including several spatial micro-truss lattice units 1 and two metal panels 2, the two metal panels 2 are arranged in parallel up and down, and several spatial micro-truss lattice units 1 are periodic Arranged between two metal panels 2, the top surface and the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com