Closure panel extension mechanism with multiple springs

A stretching mechanism and spring engagement technology, used in leaf shutters, building structures, door/window fittings, etc., which can solve large manual work, high spring coefficient, unable to provide a relatively stable manual force/torque curve force peak, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

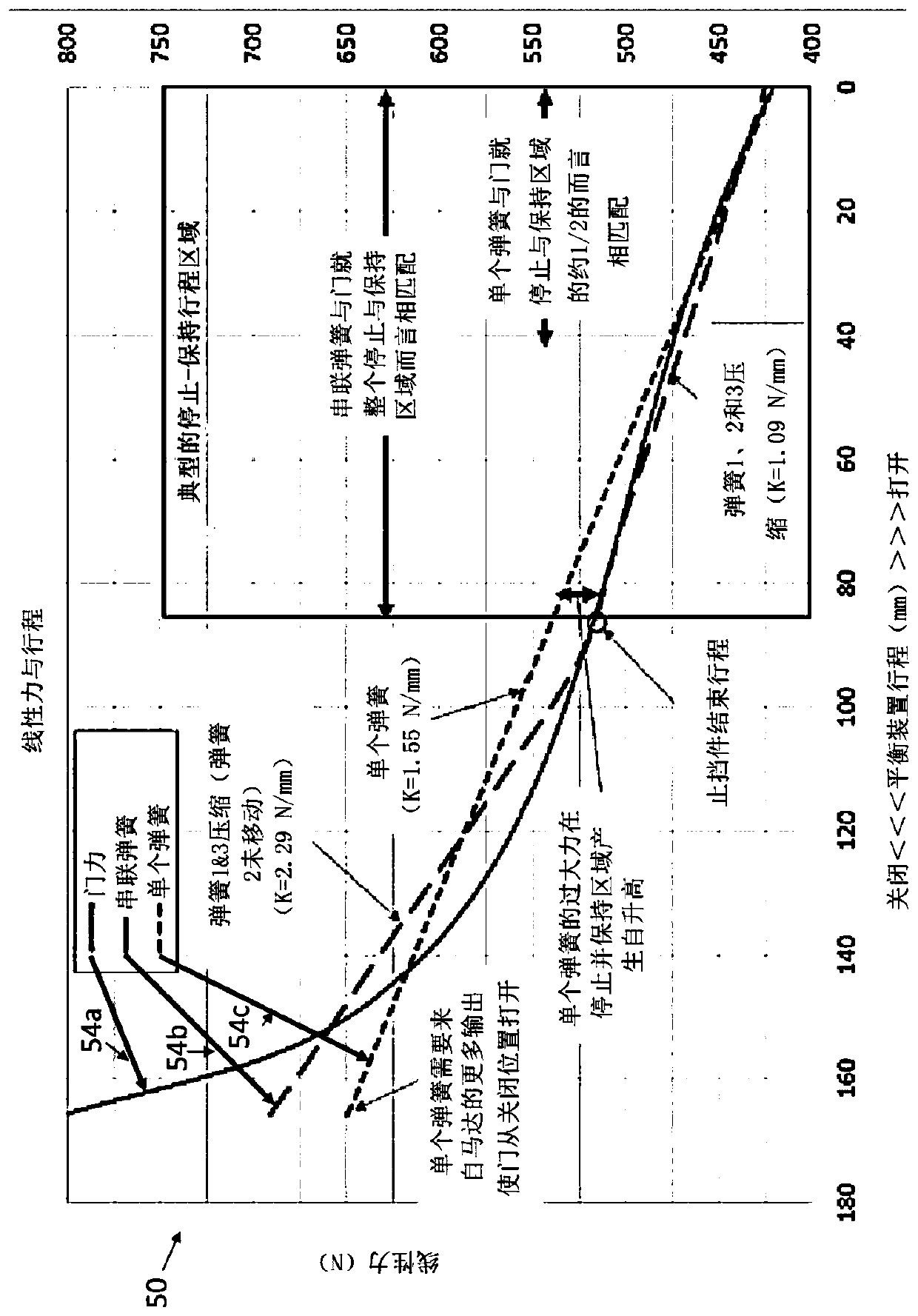

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The use of "the" is not intended to exclude the possibility of including a plurality of items in some embodiments. It will be apparent to those skilled in the art that in at least some instances in this specification and the appended claims, multiple items will be included in at least some embodiments. Likewise, use of the plural with reference to items is not intended to exclude the possibility of including one of the items in some embodiments. It will be apparent to those skilled in the art that in at least some instances of this specification and the appended claims, one of the items will be included in at least some embodiments. The expression "for example" is used herein and is understood to represent an example in Latin, which means "such as" and is not intended to limit the embodiments.

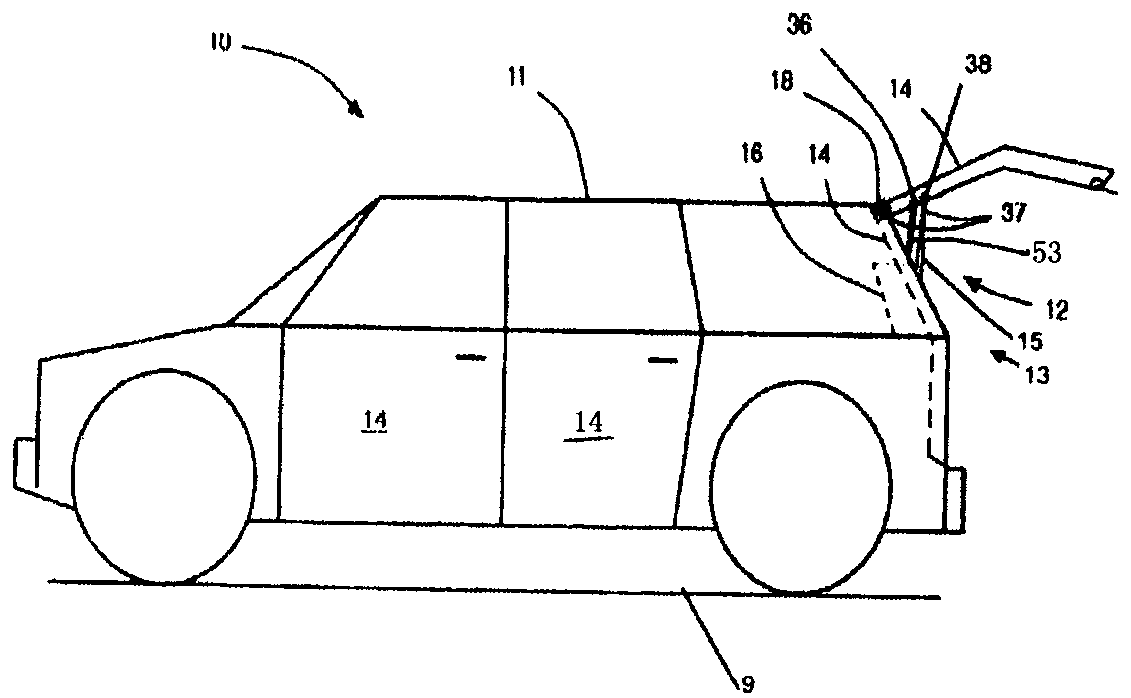

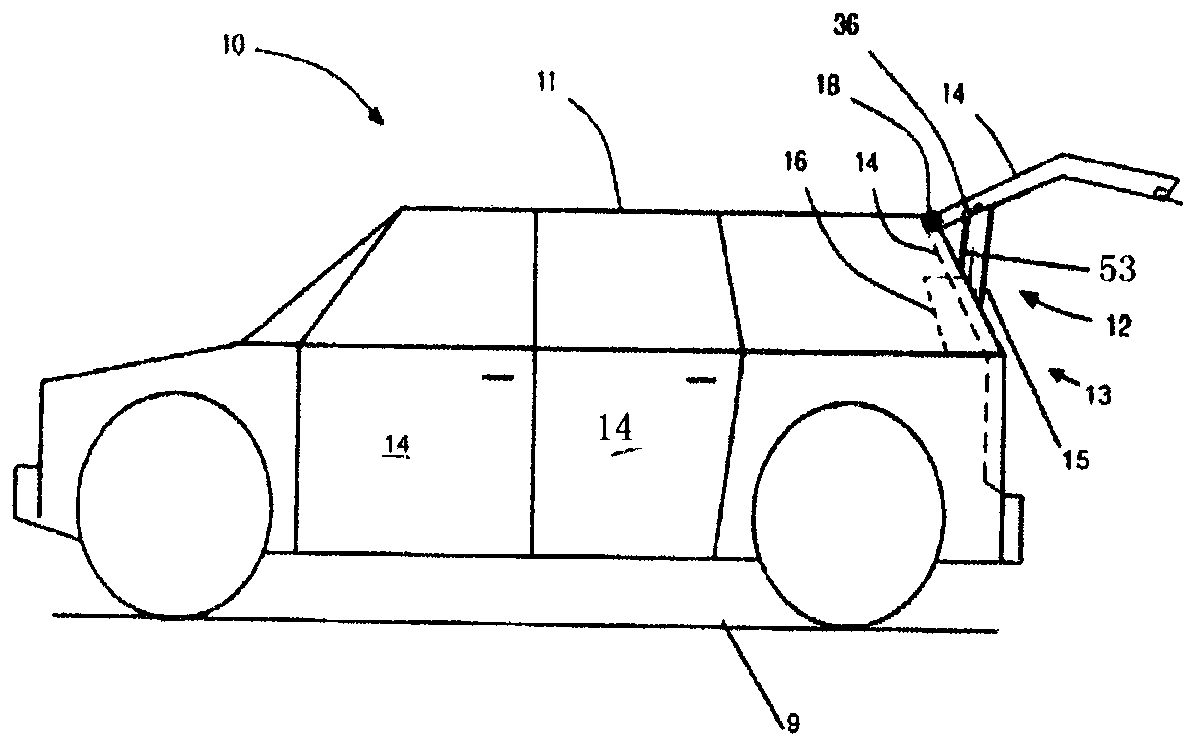

[0033] An actuator or balancing mechanism 15 is provided (i.e., an extension mechanism - see figure 1 ), the actuator or balancing mechanism 15 may advantageously be used with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com