Cable adjustment mechanism

An adjustment mechanism and cable technology, which is applied in the direction of mechanical equipment, cable installation, cable layout between relative moving parts, etc., can solve the problem of increased component price and cost, increased cable tension adjustment complexity, and increased manufacturing complexity. major issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

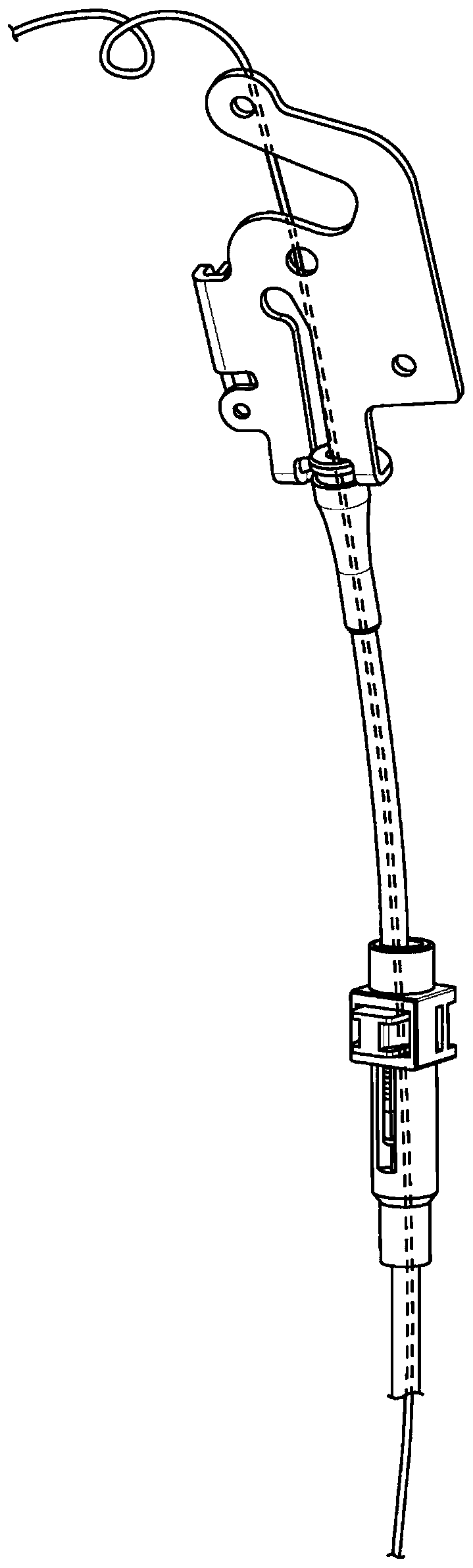

[0014] refer to figure 1 , shows the prior art of a cable adjuster for attaching a cable to a bracket via a conventional cable end sleeve and a cable adjuster in the middle of the cable. This existing solution is not preferred because the number of component elements is at least partly due to the number of cable sections, cable end sleeves with one cable section and support bracket, and splicing to other cable sections. The required assembly / configuration process for the cable conditioner in the cable section results in increased component price cost and increased manufacturing complexity. In particular, the use of multiple cable sections associated with cable end sleeves and cable adjusters also increases the complexity required for cable tension adjustment.

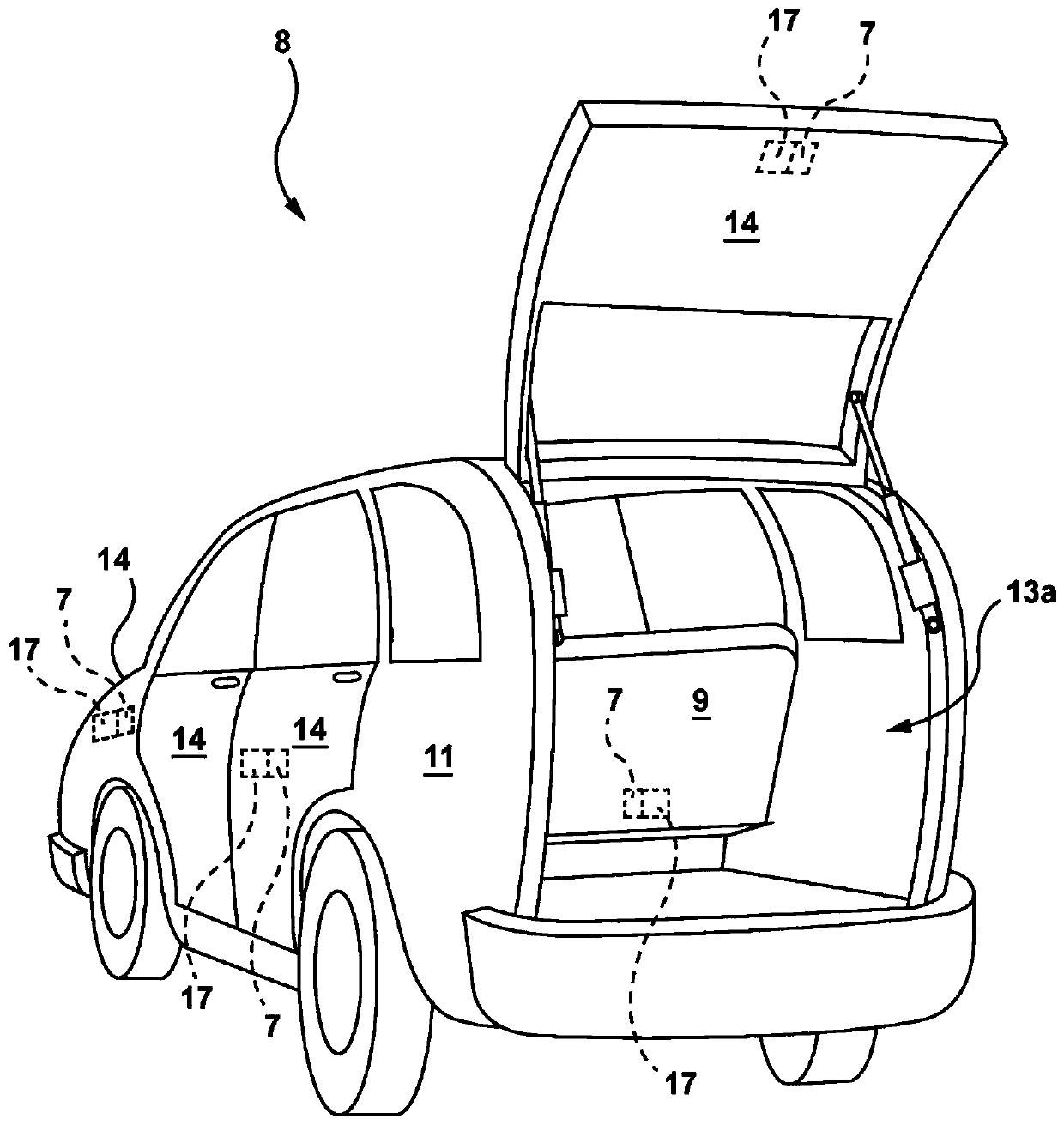

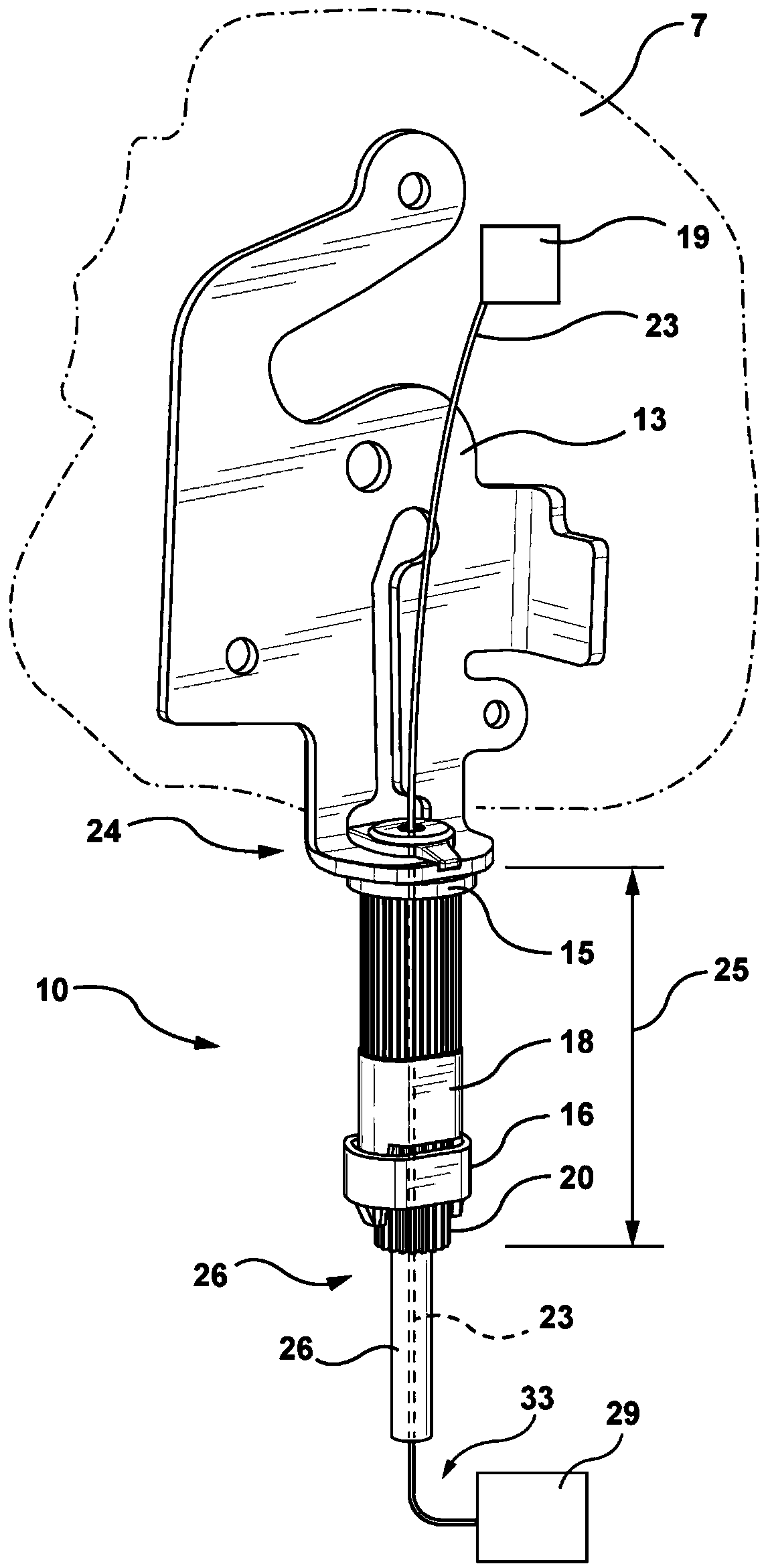

[0015] refer to image 3 and Figure 4 , shows the cable adjustment mechanism 10 for attaching and subsequently tensioning the cable assembly 22 connected to the frame 7 coupled to the vehicle body 11 , the closure p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com