UHPC steel tube concrete laminated laced column structure and construction method thereof

A technology of concrete filled steel tubes and lattice columns, which is used in bridge parts, erection/assembly of bridges, bridge materials, etc., can solve the problems of increasing construction difficulty, increasing the space occupied by piers and columns, reducing structural bearing capacity and rigidity, etc. The effect of wind and sand resistance, prolonging service life and improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

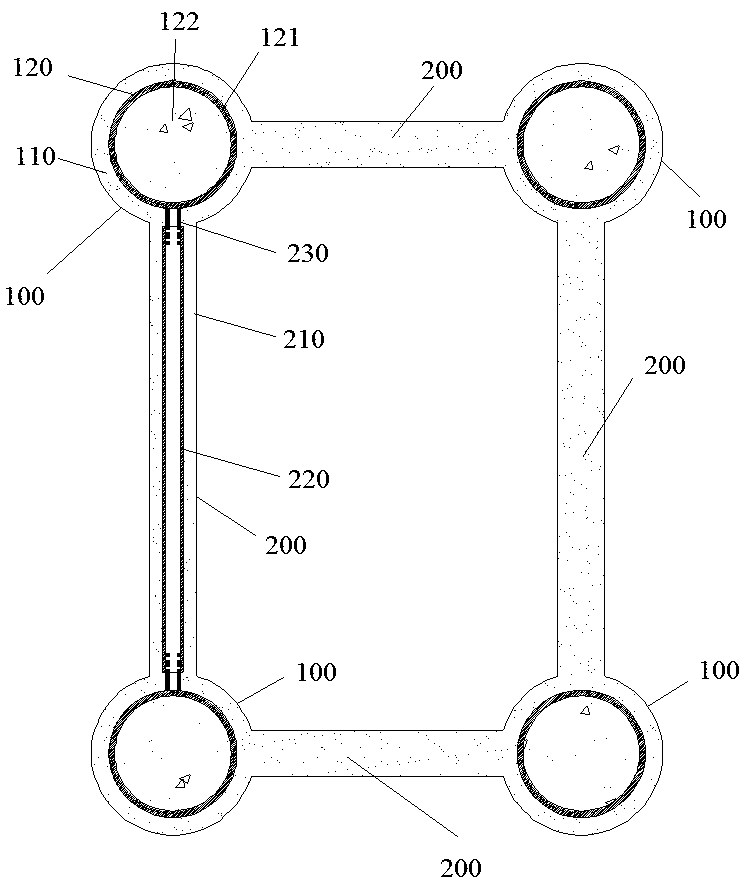

[0019] Such as figure 1 As shown, a UHPC steel pipe concrete laminated lattice column structure includes a column limb 100, and a connecting plate 200 is arranged between two adjacent column limbs 100. The composite column 120 is arranged in the UHPC layer 110 , the connecting plate 200 includes the UHPC layer 210 , the pipe extension 220 is arranged in the UHPC layer 210 , and the node connection block 230 is arranged between the pipe extension 220 and the composite column 120 .

[0020] In this embodiment, the composite column 120 includes a steel pipe 121, and a concrete column 122 is arranged inside the steel pipe 121.

[0021] In this embodiment, the connecting block 230 and the steel pipe 121 are connected by welding.

[0022] In this embodiment, the connecting block 230 and the pipe extension 220 are connected by welding.

[0023] A construction method for a UHPC steel pipe concrete superimposed lattice column structure, comprising the UHPC steel pipe concrete superim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com