Oil removal and acid pickling equipment used before galvanization of hardware

A technology of pickling equipment and hardware, which is applied in the field of hardware processing, can solve the problems of affecting the galvanizing effect of hardware, low work efficiency, and general degreasing effect, so as to improve the effect of degreasing and pickling, and improve the degree of automation and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

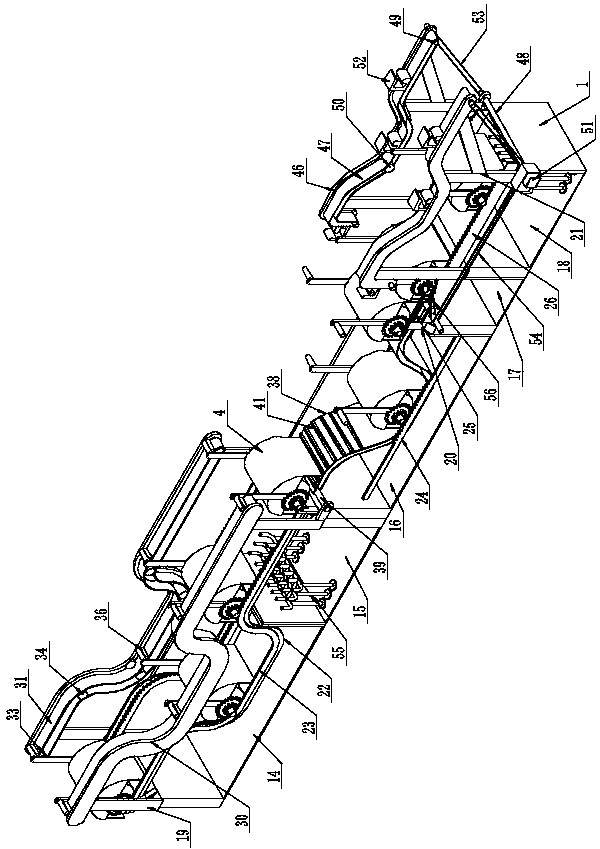

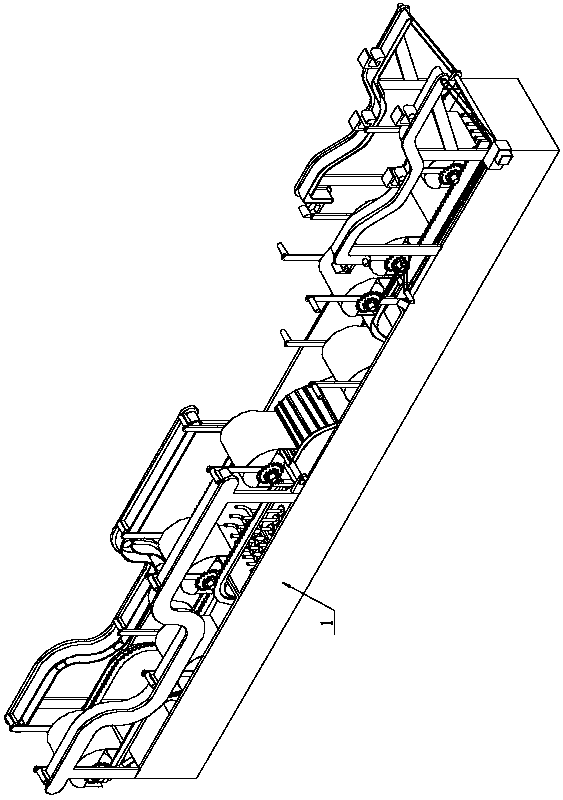

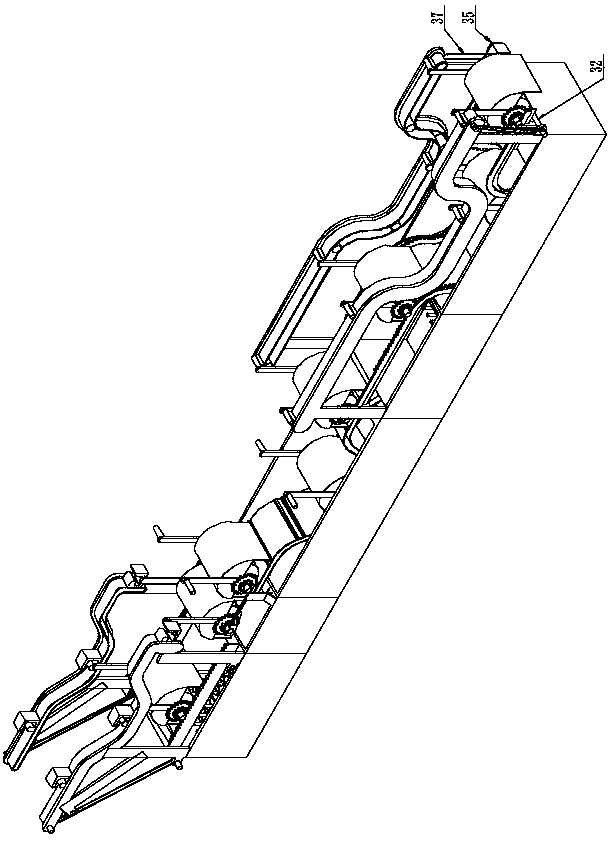

[0030] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-13As shown: there are a number of evenly distributed water filter holes 7 on the container 2, a roller cover 4 is arranged on the periphery of the container 2, and a first rotating shaft 3 is fixed on both axial ends of the container 2, and the first rotating shaft 3 It is rotatably connected with the drum cover 4, and the end of the first rotating shaft 3 away from the container 2 is equipped with a large gear 8 and a pinion 9, and one end of the first rotating shaft 3 extends into the inner cavity of the container 2 and is rotatably connected with a stopper. Plate 10, positioning column 11 is fixed on the baffle plate 10, and the end face of containing tube 2 is provided with the delivery opening 12 that cooperates with baffle plate 10, the limit opening 13 that cooperates with positioning column 11, the delivery opening 12 and the limit opening 13 Connected, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com