Bed board automatic claw nail driving machine

A claw nailing and automatic technology, which is applied in the direction of nailing tools, staple nailing tools, wood processing appliances, etc., can solve the problems of time-consuming and laborious manual installation, and a large number of claw nails, so as to achieve the degree of automation and high work efficiency. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

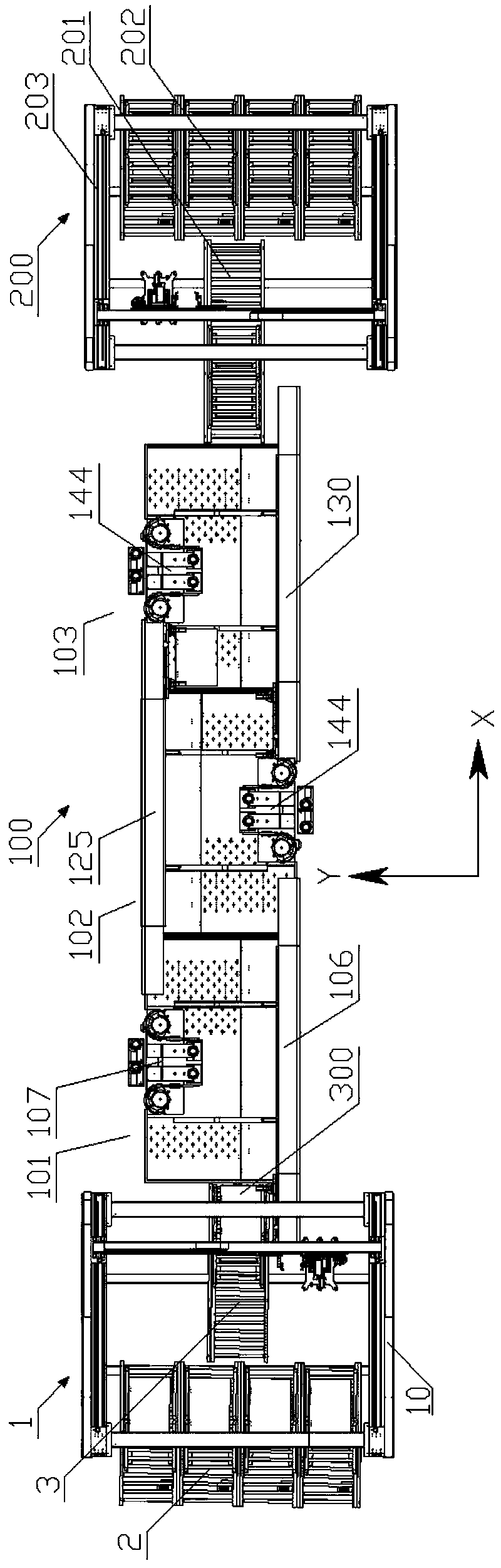

[0035] Such as figure 1 As shown, it corresponds to a bed board automatic claw nailing machine in a preferred embodiment of the present invention, which includes a loading station 1 , a claw nail installation station 100 and an unloading station 200 . The bed board 300 moves to the nail installation station 100 through the loading station 1 to install the nails, and then is sent out by the unloading station 200 .

[0036] The feeding station 1 includes a feeding conveying line 2 , a feeding conveying line 3 , and a loading gantry manipulator 10 for moving planks on the feeding conveying line 2 to the waiting conveying line 3 .

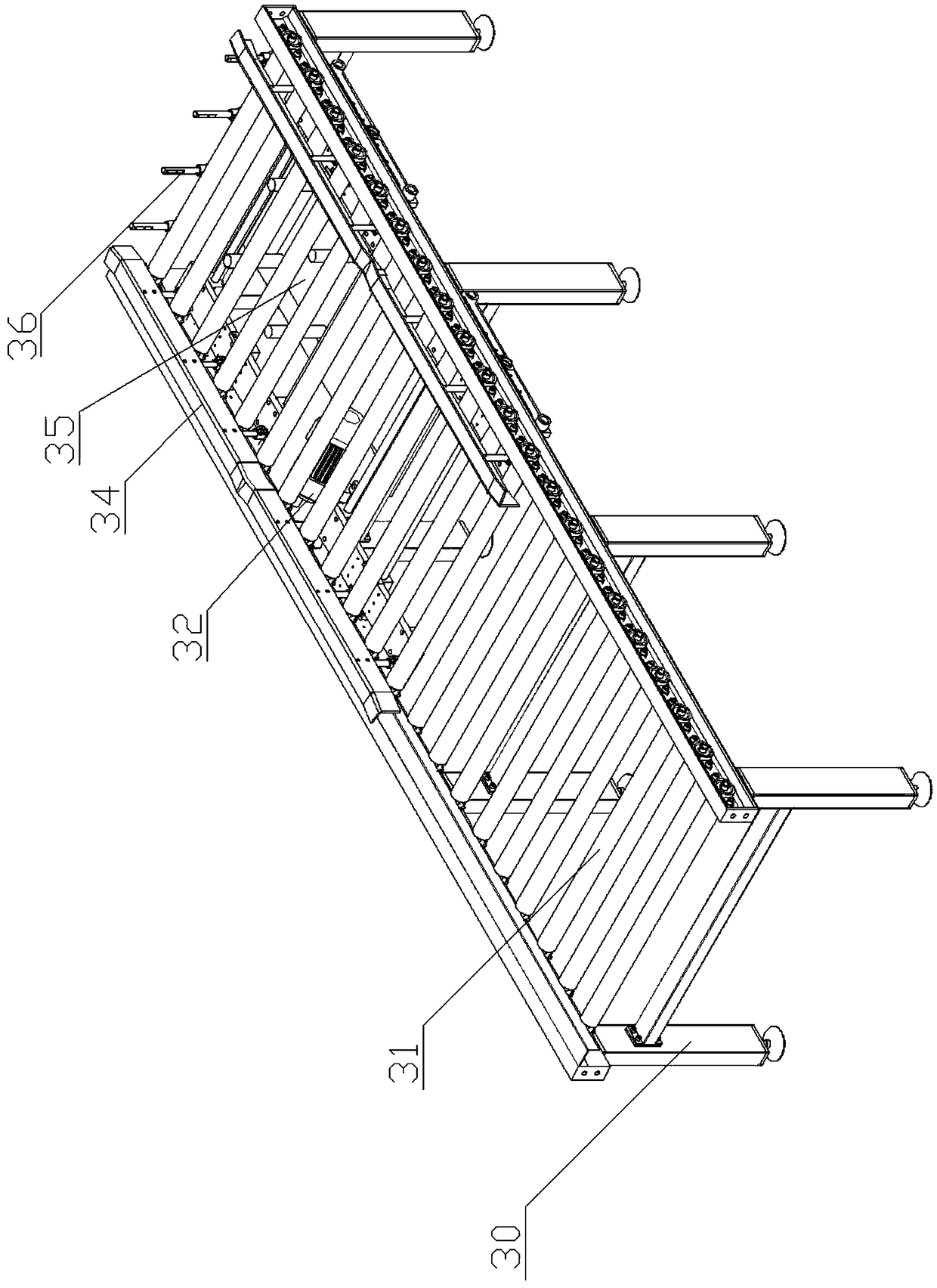

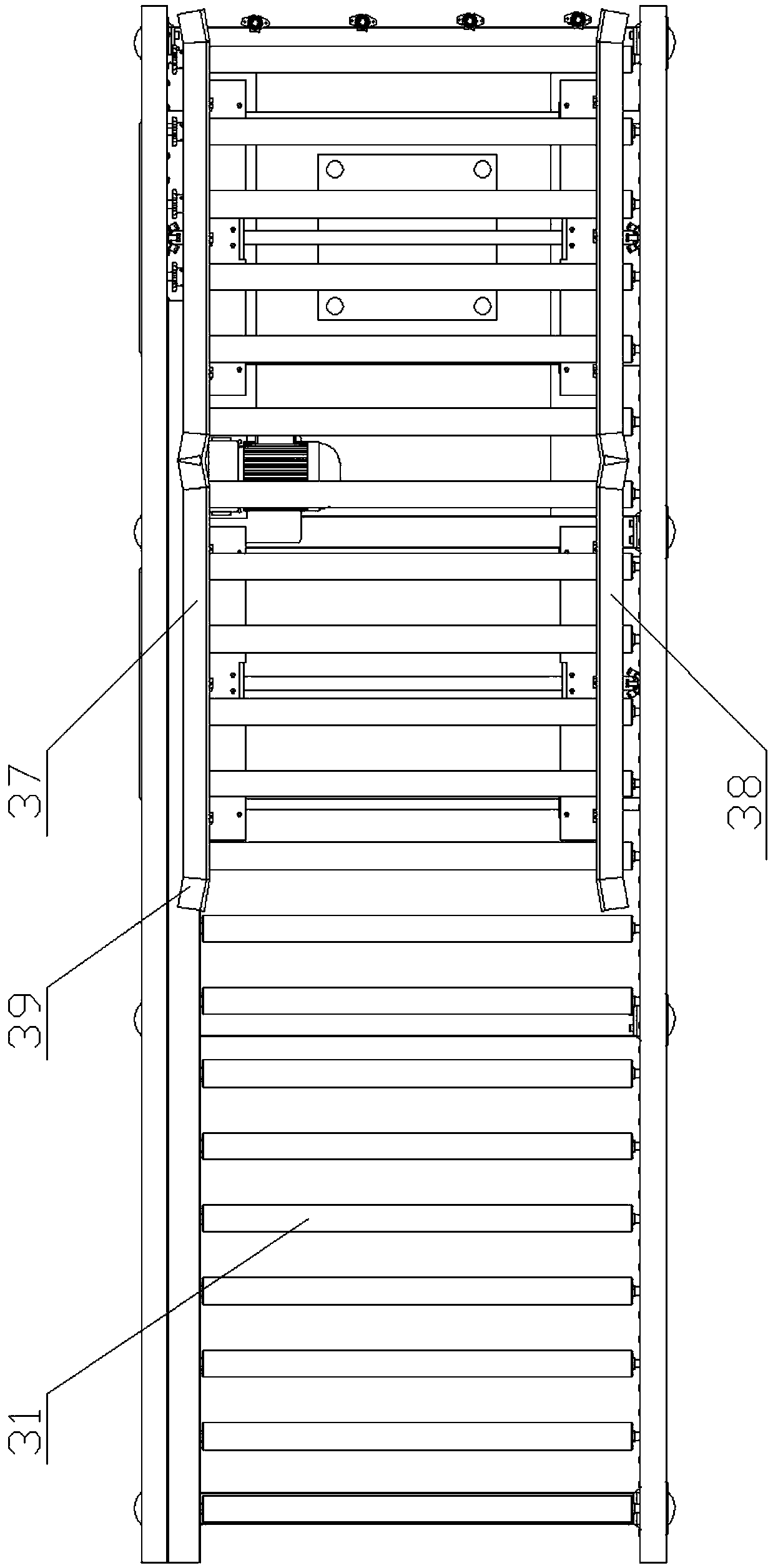

[0037] The material conveying line 3 is matched with the claw nail installation station 100, and it can adopt common conveying equipment in the prior art. In this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com