Flame-retarding type nano composite rubber material and preparation method thereof

A nano-composite and rubber material technology, applied in the field of rubber materials, can solve the problems of reducing energy consumption and time, difficulty in achieving uniform dispersion, poor combination of rubber and nano-materials, etc., to permanently improve flame retardancy, enhance flame retardancy, and improve intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

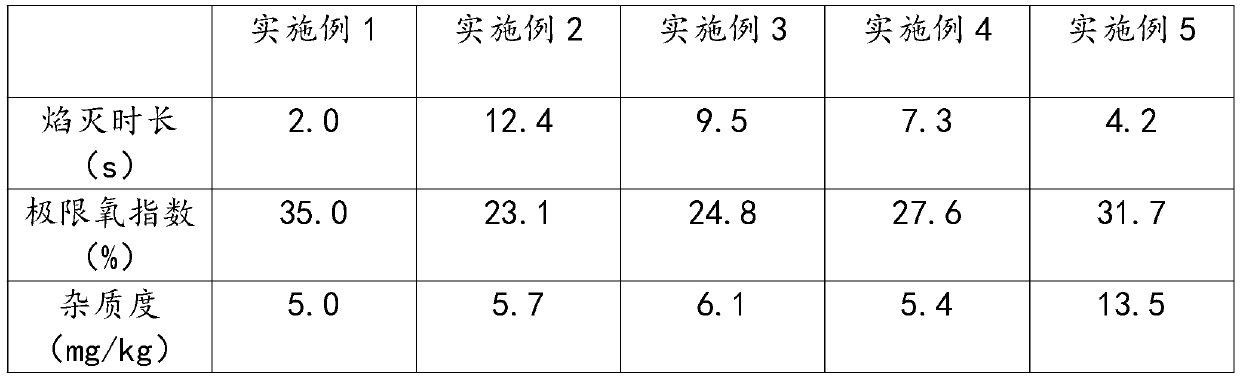

Embodiment 1

[0034] A flame-retardant nanocomposite rubber material, each raw material is composed of 60% modified rubber matrix, 25% nano powder, 10% surfactant and 5% dispersant by weight percentage;

[0035] The modified rubber matrix is composed of 20% butyl rubber, 20% styrene-butadiene rubber, 20% nitrile rubber, 17.5% polydimethylsiloxane, 10% ethanol, 7.5% benzoyl peroxide and 5% butyl titanate;

[0036] The modified rubber matrix is prepared by the following method: First, put butyl rubber, styrene-butadiene rubber and nitrile rubber together in a stirring tank with xylene as the solvent, and add butyl titanate at 90 degrees, 420 rpm Minutes to stir and dissolve for 1 hour, then introduce benzoyl peroxide and polydimethylsiloxane together, blend for 2 hours at 120 degrees, 360 rpm and helium circulation, and then reduce to 60 degrees And the ethanol is divided into three parts and introduced every 15 minutes, after extraction, drying and cooling, to obtain the modified rubber...

Embodiment 2

[0047] A flame-retardant nanocomposite rubber material, the difference from Example 1 is that the modified rubber matrix is mixed with butyl rubber, styrene-butadiene rubber and nitrile rubber in a weight percentage of 1:1:1 ; And there is no method for preparing the modified rubber matrix in Example 1.

[0048] A method for preparing a flame-retardant nanocomposite rubber material is the same as in Example 1.

Embodiment 3

[0050] A flame-retardant nanocomposite rubber material, the difference from Example 1 is that the modified rubber matrix is made of 25% butyl rubber, 25% styrene-butadiene rubber, 25% nitrile rubber, 10% Ethanol, 10% benzoyl peroxide and 5% butyl titanate;

[0051] The modified rubber matrix is prepared by the following method: First, put butyl rubber, styrene-butadiene rubber and nitrile rubber together in a stirring tank with xylene as the solvent, and add butyl titanate at 90 degrees, 420 rpm Minutes to stir and dissolve for 1 hour, then introduce benzoyl peroxide into it, blend for 2 hours at 120 degrees, 360 rpm and circulating helium injection, then reduce to 60 degrees and divide the ethanol into three parts Introduce at intervals of 15 minutes, and obtain the modified rubber matrix after extraction, drying and cooling.

[0052] A method for preparing a flame-retardant nanocomposite rubber material is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com