A creep mode temperature compensation speed regulation control method for wheel hub hydraulic drive system

A drive system, hydraulic technology, applied in the control device, driver input parameters, vehicle components and other directions, can solve the temperature rise problem of the wheel hub hydraulic drive system control accuracy, interference and other problems, to improve the temperature adaptability, improve the bearing performance, The effect of improving the starting acceleration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

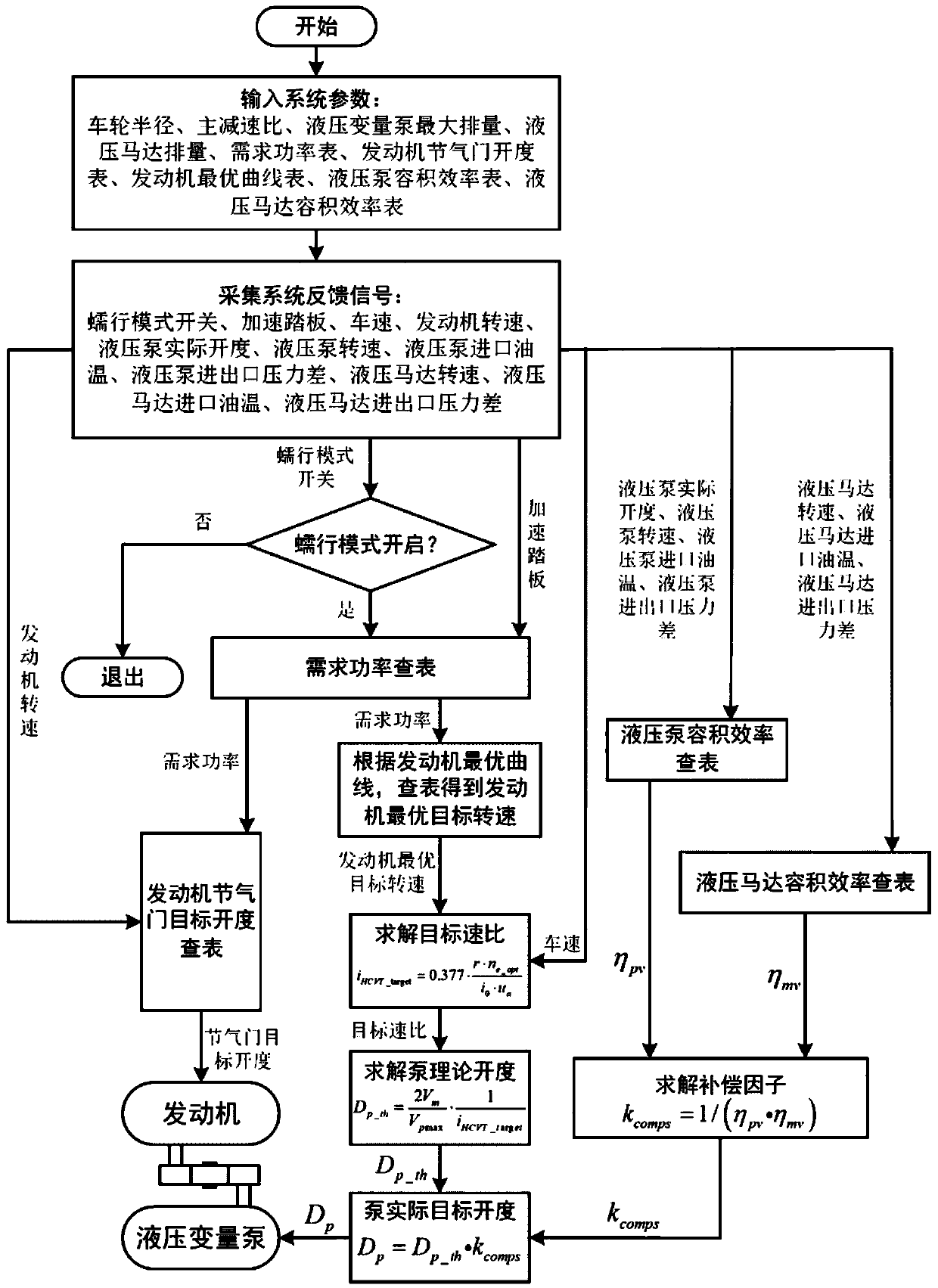

[0058] The present invention will be described in detail below in conjunction with the drawings:

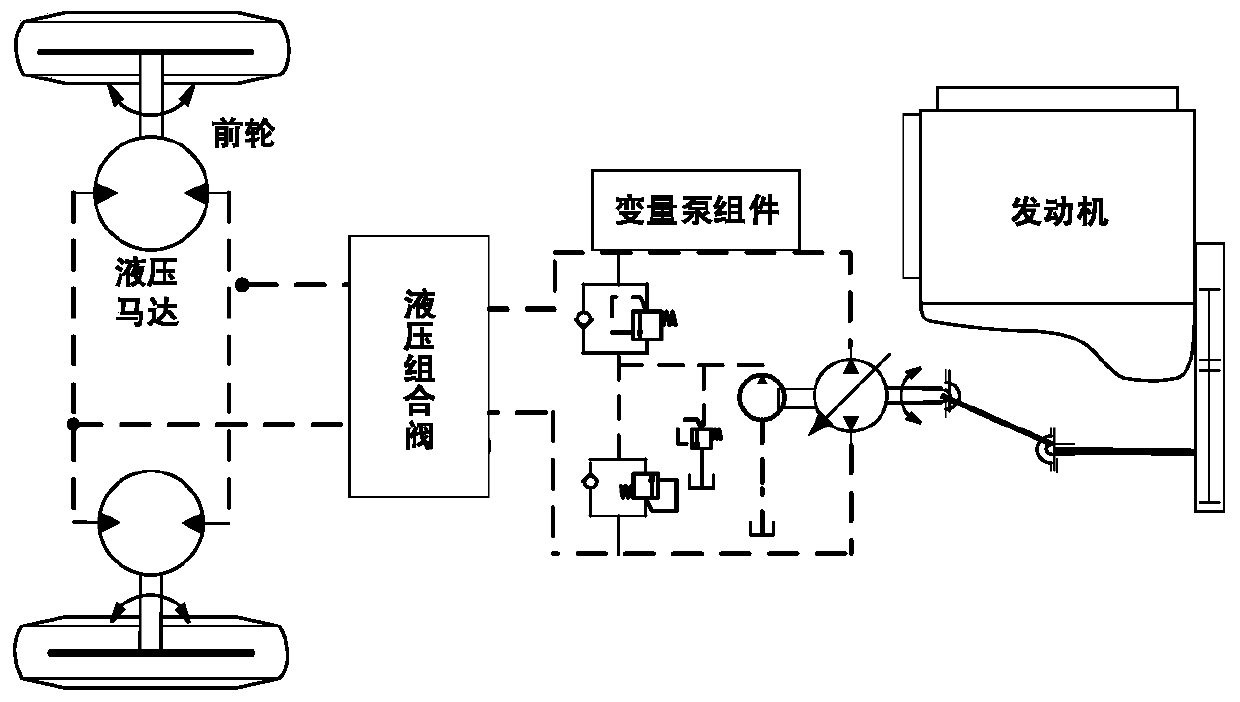

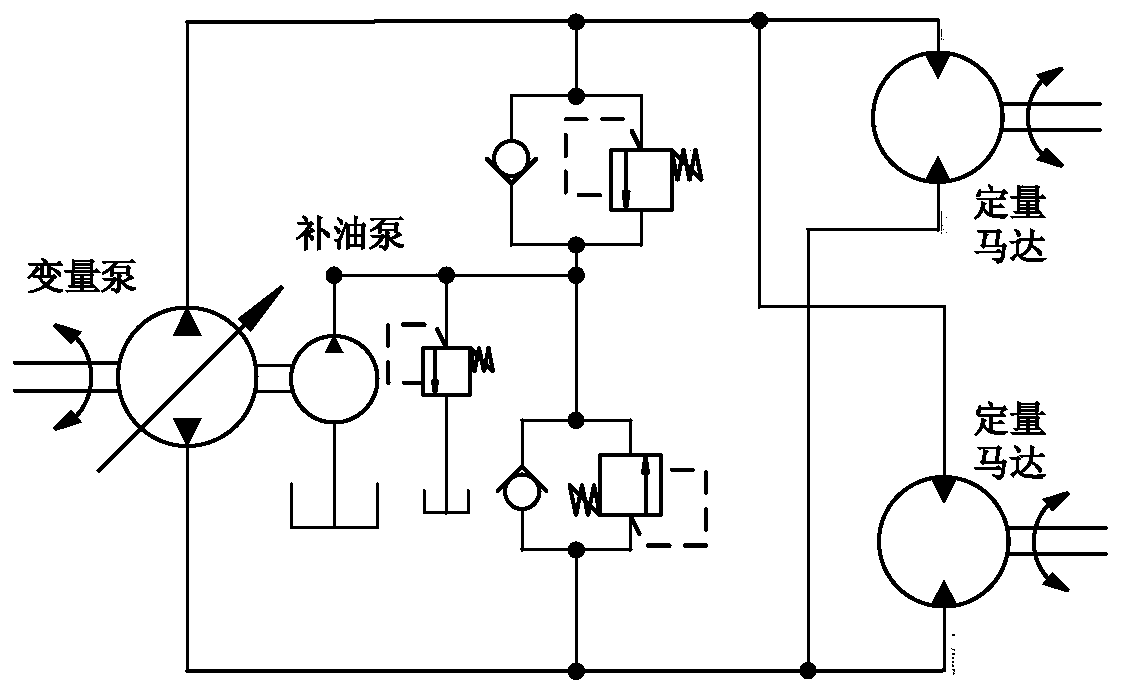

[0059] The invention discloses a creep mode temperature compensation speed regulation control method of a wheel hub hydraulic drive system, which adopts CAN wire or hard wire acquisition system feedback signal, including creep mode switch signal, accelerator pedal signal, vehicle speed signal, engine speed signal, Hydraulic pump actual opening signal, hydraulic pump speed signal, hydraulic pump inlet oil temperature signal, hydraulic pump inlet and outlet pressure difference signal, hydraulic motor speed signal, hydraulic motor inlet oil temperature signal, hydraulic motor inlet and outlet pressure difference signal. The basic principle of the control system is to determine whether the creep mode is turned on by the collected creep mode switch signals. According to the speed regulation characteristics of the closed circuit of the hydraulic system, the wheel hub hydraulic drive system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com