Production method and production line for ceramic tiles in which fixed patterns dynamically printed through rubber-covered rollers correspond to ink-jet patterns dynamically printed through ink jetting

A production method and corresponding technology are applied in the field of ceramic tile production methods and production lines, which can solve the problems of inability to realize the correspondence of decorative patterns, difficult application, and lack of corresponding relationships, so as to achieve rich decorative patterns, meet personalized decoration, and enrich decoration. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The method for producing ceramic tiles in which the fixed pattern dynamically printed by the rubber roller corresponds to the inkjet pattern dynamically printed by the inkjet of this embodiment includes the following steps:

[0043] Step a. Pre-set the printing procedures and sequence of the rubber roller printing machine and the digital inkjet printing machine:

[0044] Make the n fixed patterns to be printed on the rubber roller of the rubber roller printing machine, and set the printing procedure and sequence of the n fixed patterns in advance; make the inkjet patterns that the digital inkjet printer needs to print, And pre-set the printing procedure and sequence of the inkjet pattern; where n is a positive integer;

[0045] Step b, first carry out rubber roller printing:

[0046] When the raw ceramic tiles enter the rubber roller printing machine one by one, follow the following printing procedures:

[0047] First print the first fixed pattern on the first rubber roller on t...

Embodiment 2

[0056] The method for producing ceramic tiles in which the fixed pattern dynamically printed by the rubber roller corresponds to the inkjet pattern dynamically printed by the inkjet of this embodiment includes the following steps:

[0057] Step a. Pre-set the printing procedures and sequence of the rubber roller printing machine and the digital inkjet printing machine:

[0058] Make the n fixed patterns to be printed on the rubber roller of the rubber roller printing machine, and set the printing procedure and sequence of the n fixed patterns in advance; make the inkjet patterns that the digital inkjet printer needs to print, And pre-set the printing procedure and sequence of the inkjet pattern; where n is a positive integer;

[0059] Step c. Inkjet printing first:

[0060] When the ceramic tile raw materials enter the digital inkjet printing machine one by one, follow the following printing procedures:

[0061] Print the first inkjet pattern on the fixed area of the first ceramic ti...

Embodiment 3

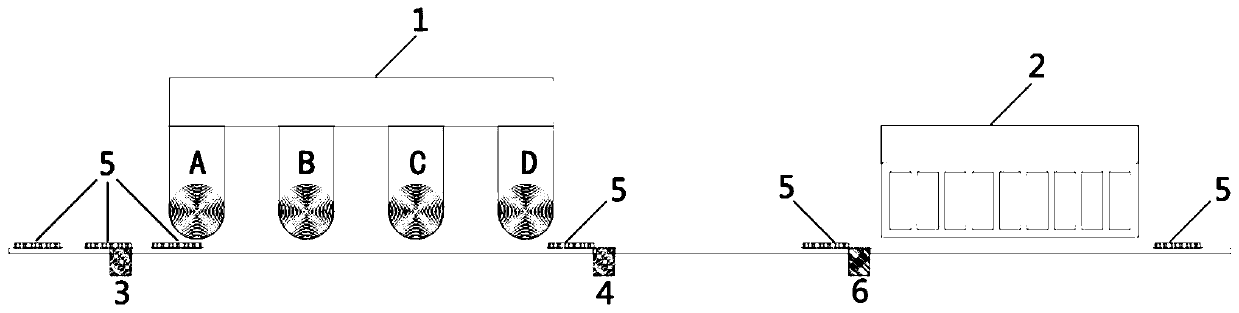

[0071] In this embodiment, a ceramic tile production line in which the fixed pattern dynamically printed by the rubber roller corresponds to the inkjet pattern dynamically printed by the inkjet, such as figure 1 As shown, it includes a sensor 3, a rubber roller printer 1, a code printer 4, a code scanner 6, and a digital inkjet printer 2 for sensing the position of the ceramic tile green embryo 5. A fixed pattern corresponding to the fixed area of the ceramic tile embryo 5 is printed, and then the encoder 4 generates barcode information corresponding to the fixed pattern on the ceramic tile embryo 5 and can be recognized by the barcode scanner 6, and then the barcode scanner 6 Transmit the barcode information to the digital inkjet printer 2, and then the ceramic tile embryo 5 carrying the fixed pattern and corresponding barcode information enters the digital inkjet printer 2, and the digital inkjet printer 2 is fixed on the ceramic tile embryo 5. An inkjet pattern correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com