Laminated nonwoven fabric for protection suits as well as production method and application of laminated nonwoven fabric

A manufacturing method and technology of non-woven fabrics, applied in protective clothing, protective equipment, chemical instruments and methods, etc., can solve the problems of heavy garments, low air permeability, and high-quality laminated fabrics, and achieve high oil resistance and air permeability High, high capture efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

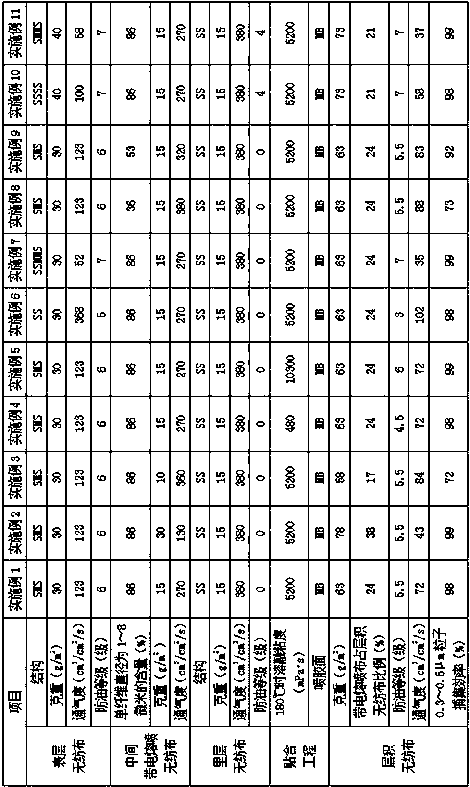

Examples

preparation example Construction

[0027] (1) Preparation of surface and inner layer non-woven fabrics: Spun-bonded non-woven fabrics are obtained through spun-bonding processing technology, and the prepared spun-bonded non-woven fabrics are respectively used as a layer of non-woven fabrics in the surface layer and the inner layer; The spunbonded non-woven fabric is made by heating and melting the high molecular polymer, extruding the melt from the spinning hole into the air through the extruder, and stretching the melt stream at a certain speed while cooling in the air. Thin and long (airflow or mechanical action), at this stage, the polymer melt is refined and solidified at the same time, forming fibers and then forming a network to obtain a spunbonded non-woven fabric;

[0028] (2) Waterproof and oil-proof processing of the surface non-woven fabric: the spunbonded non-woven fabric prepared in step (1) is subjected to a padding or spraying process to obtain a spunbonded non-woven fabric with waterproof and oil...

Embodiment 1

[0049] (1) Preparation of surface and inner layer non-woven fabrics: Spunbond / meltblown / spunbond nonwoven fabrics (SMS) for the surface layer and spunbond / spunbond nonwoven fabrics for the inner layer are prepared through spunbond and meltblown processes respectively. Cloth (SS), the grammage is 30g / m 2 The surface layer of non-woven fabric and the weight is 15g / m 2 The inner non-woven fabric;

[0050] (2) Waterproof and oil-proof processing of surface non-woven fabric: impregnate the spunbond / meltblown / spunbond non-woven fabric (SMS) prepared in step (1) in oil-repellent treatment agent: penetrating agent: bridging agent: water =20g / L: 6g / L: 15g / L: 59g / L in the mixed solution, after heat setting and drying treatment, the oil resistance level is 6, and the air permeability is 123cm 3 / cm 2 / s SMS non-woven fabric;

[0051] (3) Preparation of intermediate melt-blown non-woven fabric: Polypropylene fiber is used through melt-blown processing technology to obtain a grammage o...

Embodiment 2

[0054] (1) Preparation of surface and inner layer non-woven fabrics: Spunbond / meltblown / spunbond nonwoven fabrics (SMS) for the surface layer and spunbond / spunbond nonwoven fabrics for the inner layer are prepared through spunbond and meltblown processes respectively. Cloth (SS), the grammage is 30g / m 2 The surface layer of non-woven fabric and the weight is 15g / m 2 The inner non-woven fabric;

[0055] (2) Waterproof and oil-proof processing of surface non-woven fabric: impregnate the spunbond / meltblown / spunbond non-woven fabric (SMS) prepared in step (1) in oil-repellent treatment agent: penetrating agent: bridging agent: water =20g / L: 6g / L: 15g / L: 59g / L in the mixed solution, after heat setting and drying treatment, the oil resistance level is 6, and the air permeability is 123cm 3 / cm 2 / s SMS non-woven fabric;

[0056] (3) Preparation of intermediate melt-blown non-woven fabrics: Polypropylene fibers are used through melt-blown processing technology to obtain a grammag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com