Forming welding equipment for I-steel production

A technology of welding equipment and I-beam, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., which can solve problems such as the limitation of the flip angle range, the inability to accurately adjust the welding angle, and structural limitations, so as to avoid potential safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

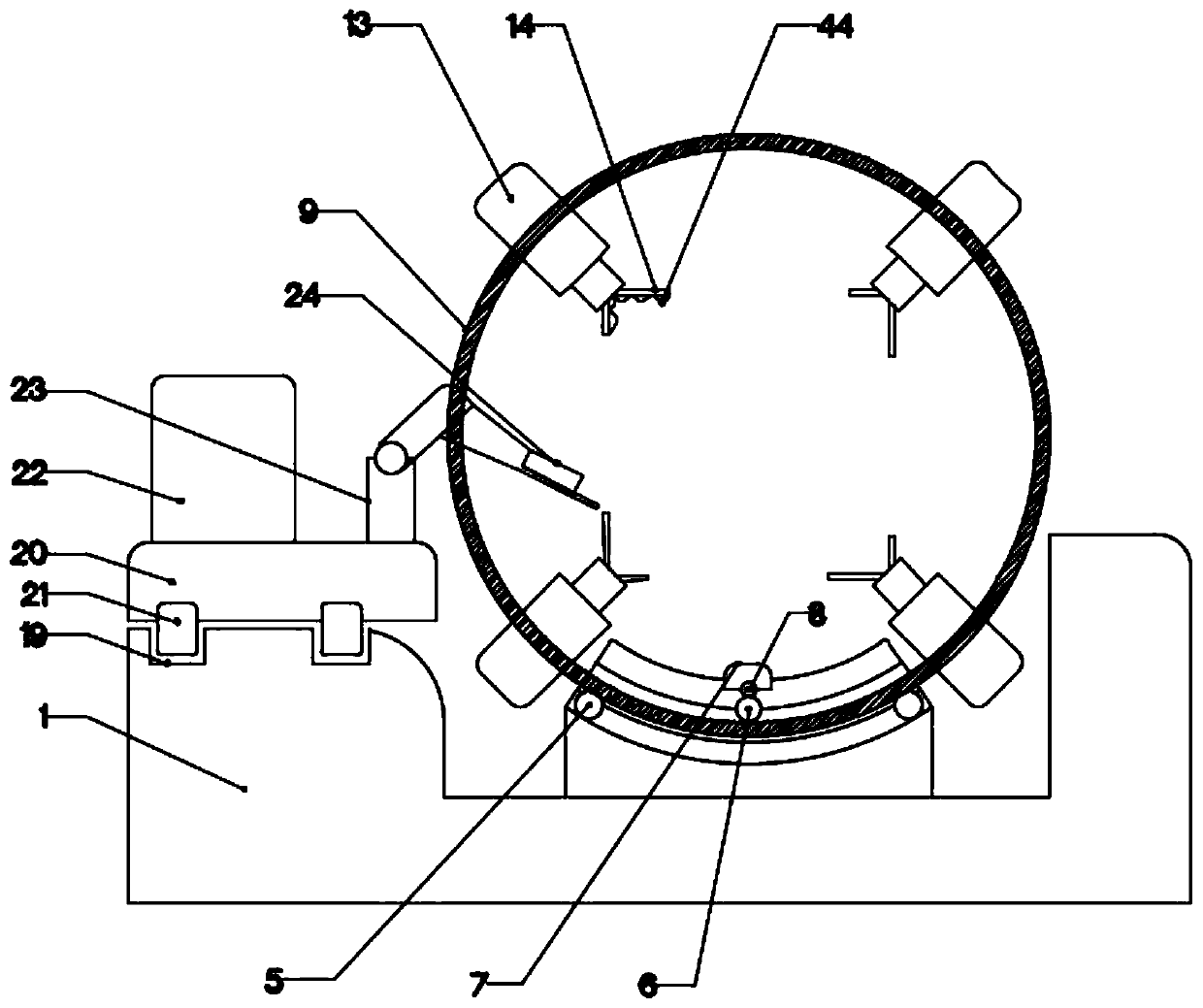

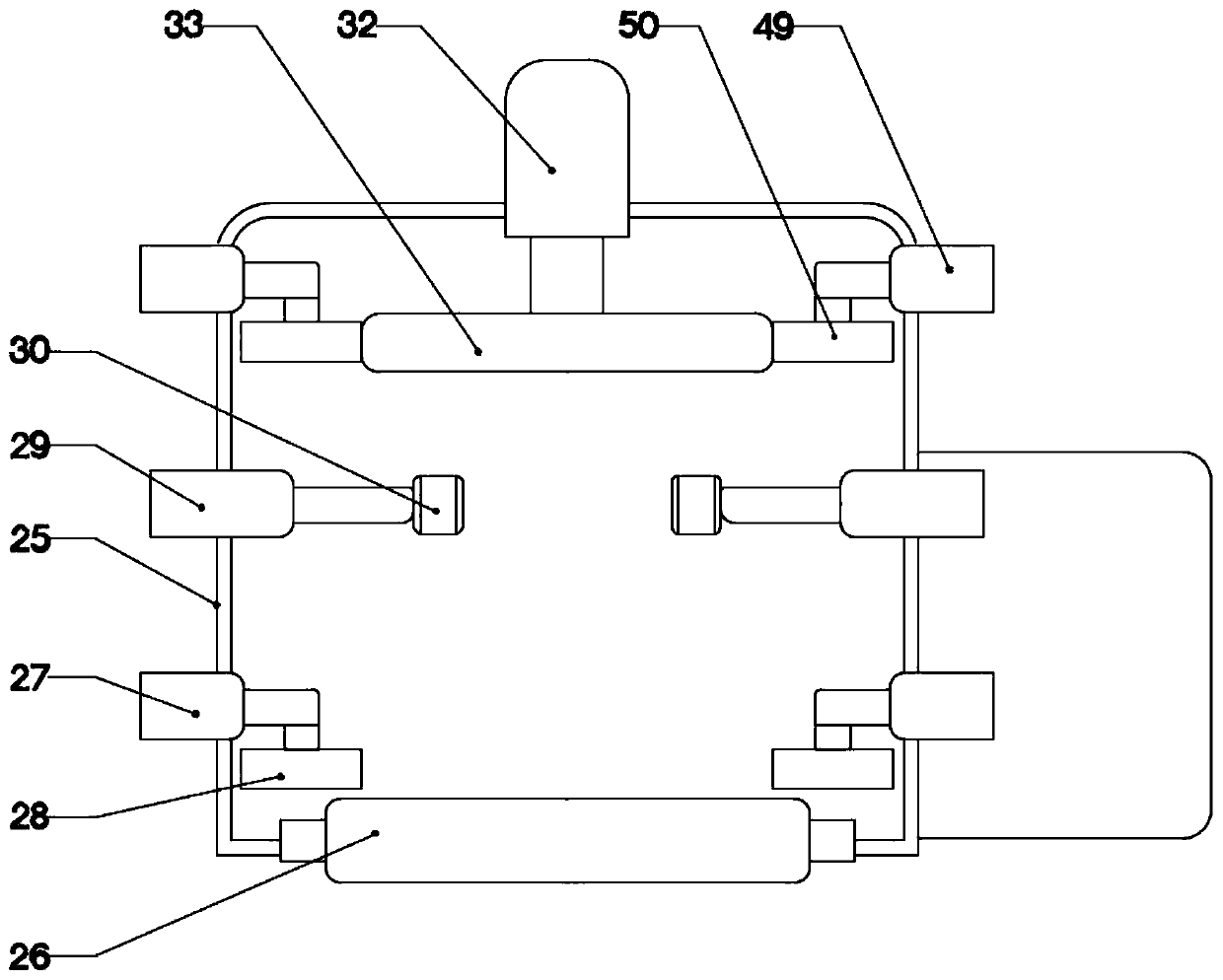

[0023] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 shown.

[0024] In this embodiment, the model of controller 41 is CPM1A-DA002 model, and the signal output terminal of controller 41 is connected with drive motor 7, hydraulic pump 46, drive wheel 21, welder one 22, welder two 42, drive roller One 26, telescopic rod one 27, telescopic rod two 29, the signal input end of suction pump 39 are electrically connected, the power output end of controller 41 is connected with drive motor 7, hydraulic pump 46, drive wheel 21, welder one 22, Welding machine two 42, driving roller one 26, telescopic rod one 27, telescopic rod two 29, and the power supply input end of suction pump 39 are electrically connected.

[0025] The invention of this application lies in the structural design of the full-angle overturn welding device, which is combined with the attached figure 2 and 5 The full-angle flip welding device drives th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com