Accumulation conveyor

A technology of accumulating and releasing conveyors and conveying trolleys, which is applied in the directions of conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems that the conveyor cannot run on time, cannot be turned over safely, and the structure of the conveyor is complex. Compact, simple structure and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below with specific embodiments, but it should be noted that the protection scope of the present invention is not limited thereto.

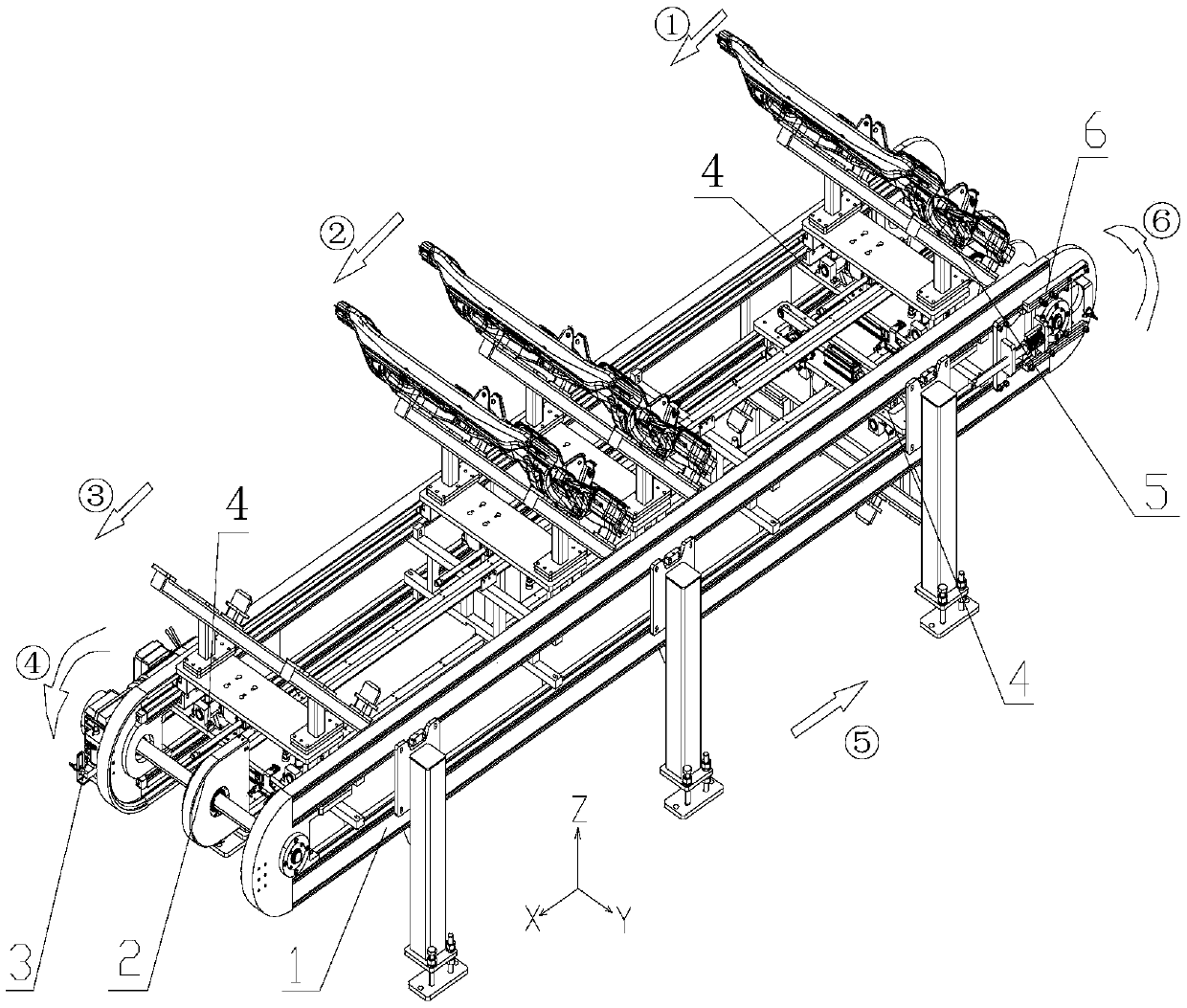

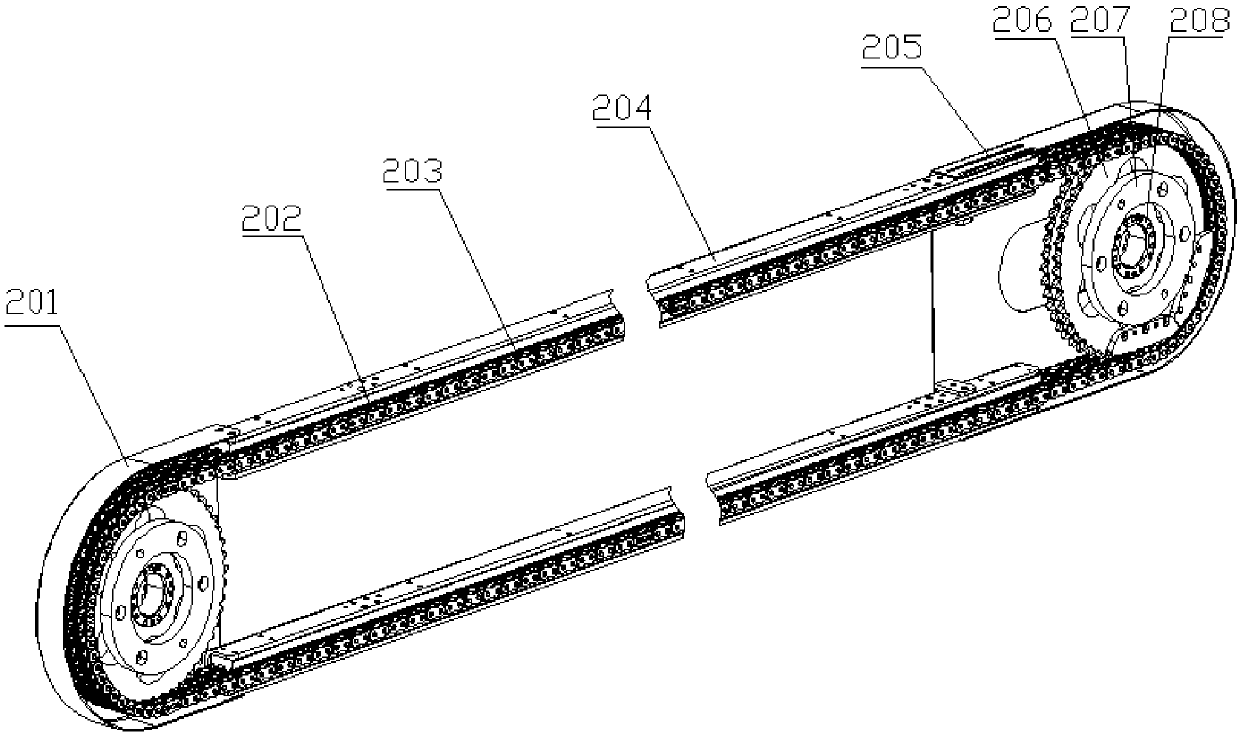

[0026] Attached below Figure 1 to Figure 5 The present invention is further described (the directions mentioned below: the X, Y, Z coordinate directions mentioned in the text are consistent with the standard Cartesian coordinates).

[0027] figure 1 Described is a kind of accumulative and free conveyor of the present invention, comprising: body 1, sprocket drive mechanism 2, overload protection device 3, stop device 4, conveying trolley 5, chain automatic tensioning mechanism 6 these several parts composition, Conveying dolly 5 can have many vehicles.

[0028] The working state of the accumulative conveyor of the present invention includes: the robot loading state ①, the accumulating stage (up) ②, the robot picking up state ③, the conveying trolley turning down stage ④, the accum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com