20KW laser cutting machine

A laser cutting machine, 20KW technology, applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems that can only be fixed on the machine body, the dust removal effect of the exhaust mechanism is not obvious, and the size of the laser generator is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

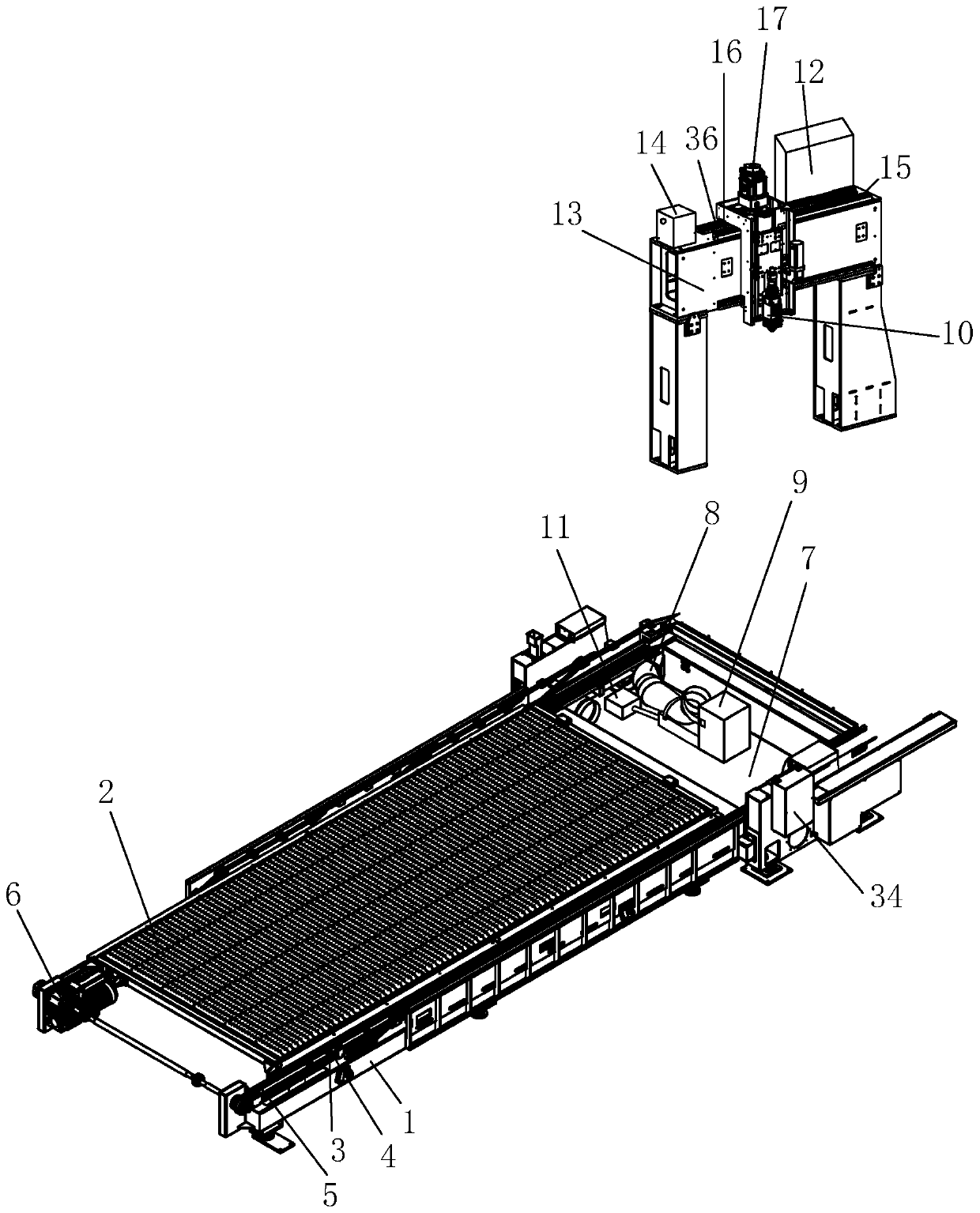

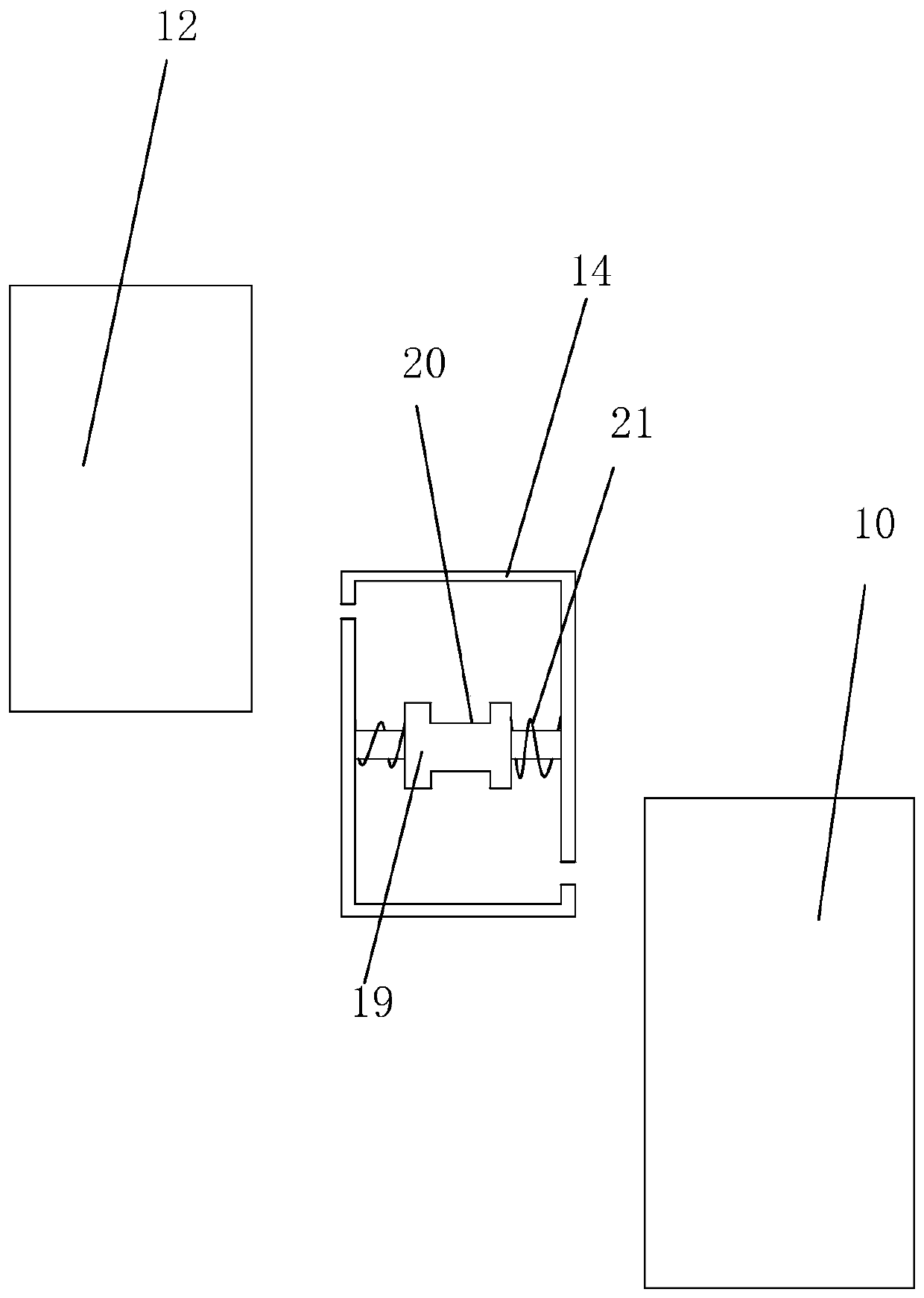

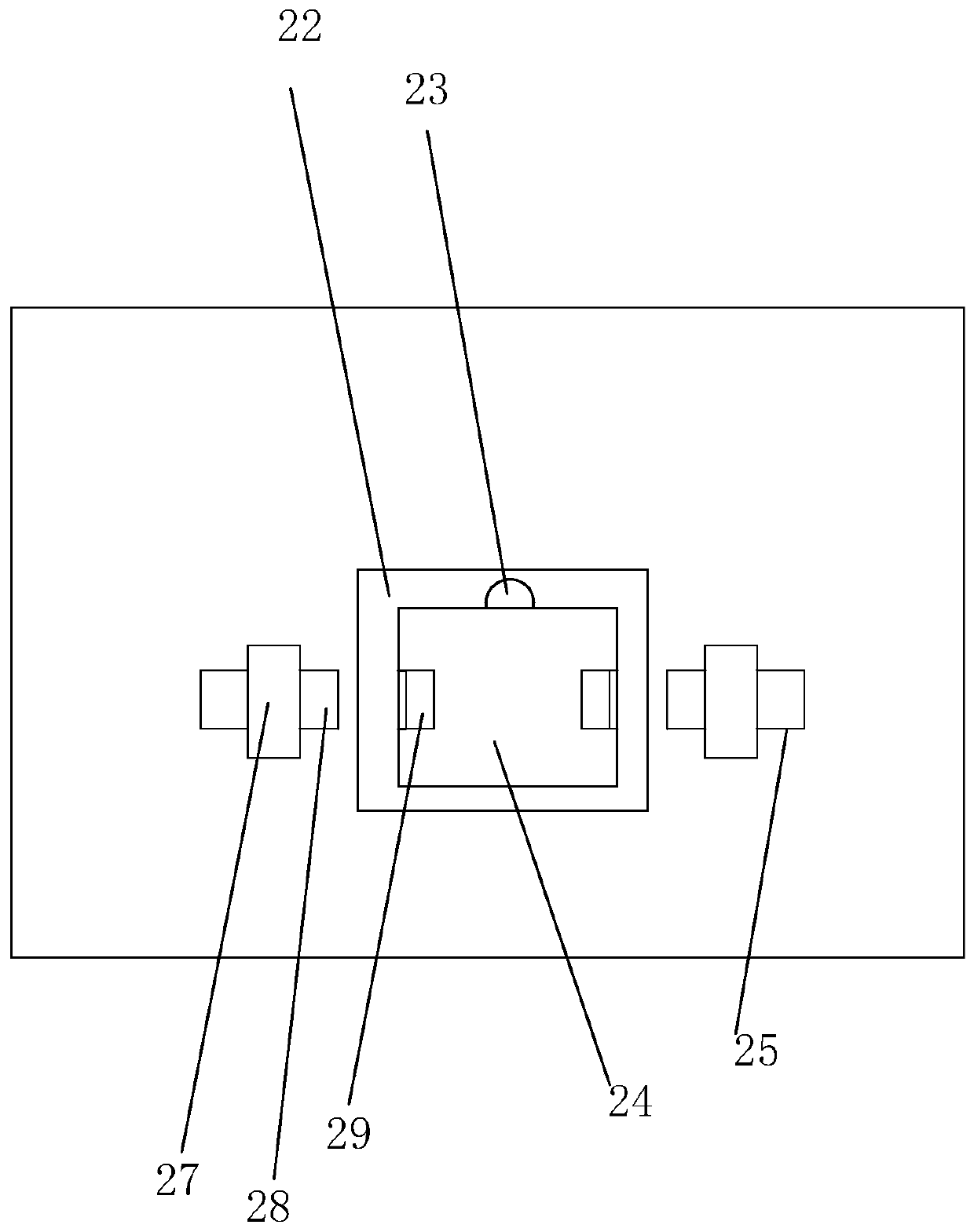

[0023] The present invention will be further described with reference to the accompanying drawings.

[0024] A 20KW laser cutting machine, such as Figure 1-Figure 5 As shown, including a machine tool 1, a triangular bearing plate 2 is arranged on the top of the machine tool 1, and both sides of the bearing plate 2 are fixedly connected with a plurality of fixed rods 3, and each fixed rod 3 is sleeved with a rotating shaft 4. The rotating shaft 4 and the conveyor belt 5 are in a fixed connection, and the rotating shaft 4 will move along with the conveyor belt 5 without rotation. A plurality of the rotating shafts 4 are socketed with the same conveyor belt 5, and one end of the conveyor belt 5 is provided with a first motor 6 that drives the conveyor belt 5 to rotate, and the machine tool 1 is fixedly connected with a concave plate 7 below the bearing plate 2 , the concave plate 7 is pierced with a bellows 8 connected to the exhaust fan 24, and one end of the bellows 8 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com