Eddy current testing equipment of piston rod

An eddy current flaw detection and piston rod technology, which is applied in the field of flaw detection and detection, can solve the problems of insufficient intelligence in classification, low degree of automation, and high labor intensity, and achieve the effect of simple and compact overall structure design, high degree of automation, and improved detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the content of the present invention, the present invention will be described in detail below in conjunction with specific examples.

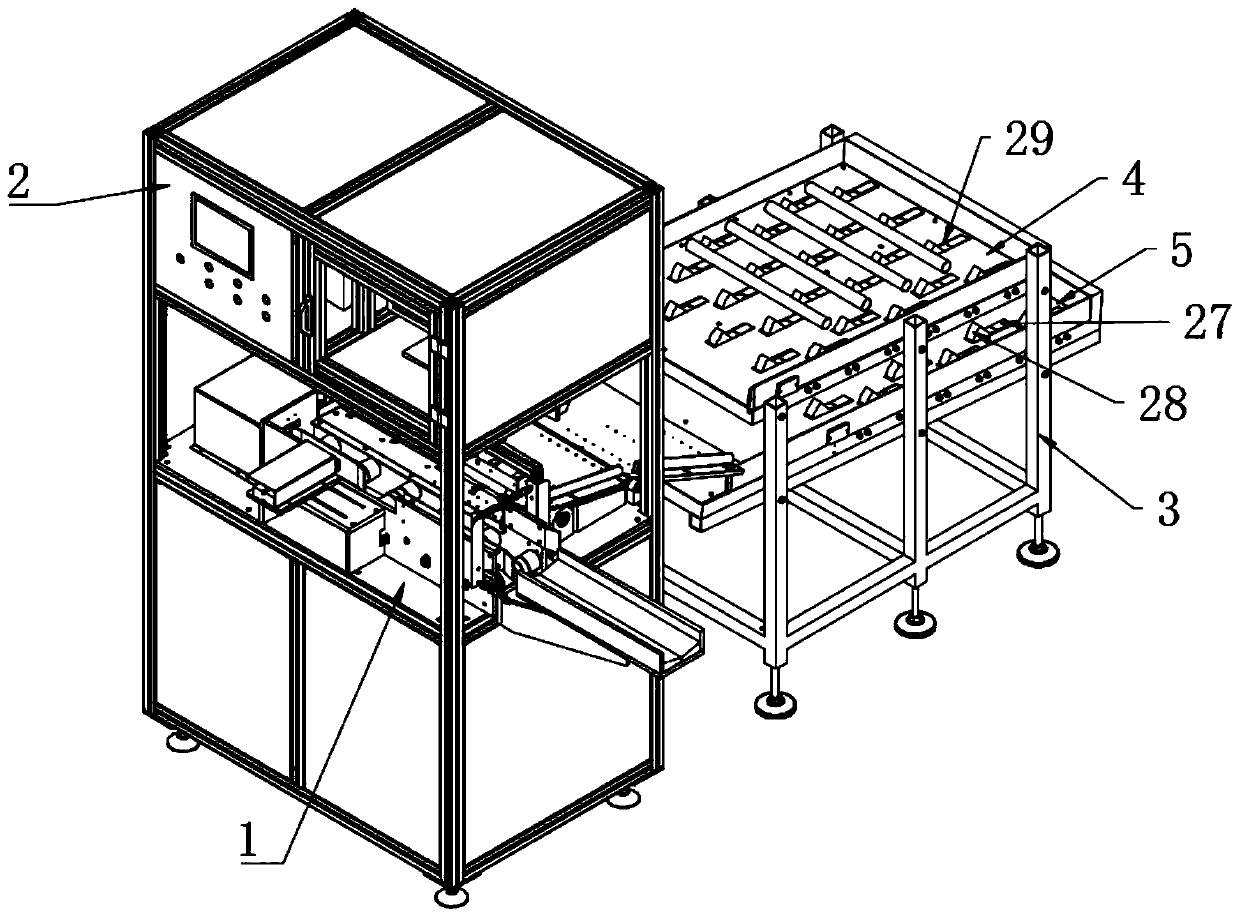

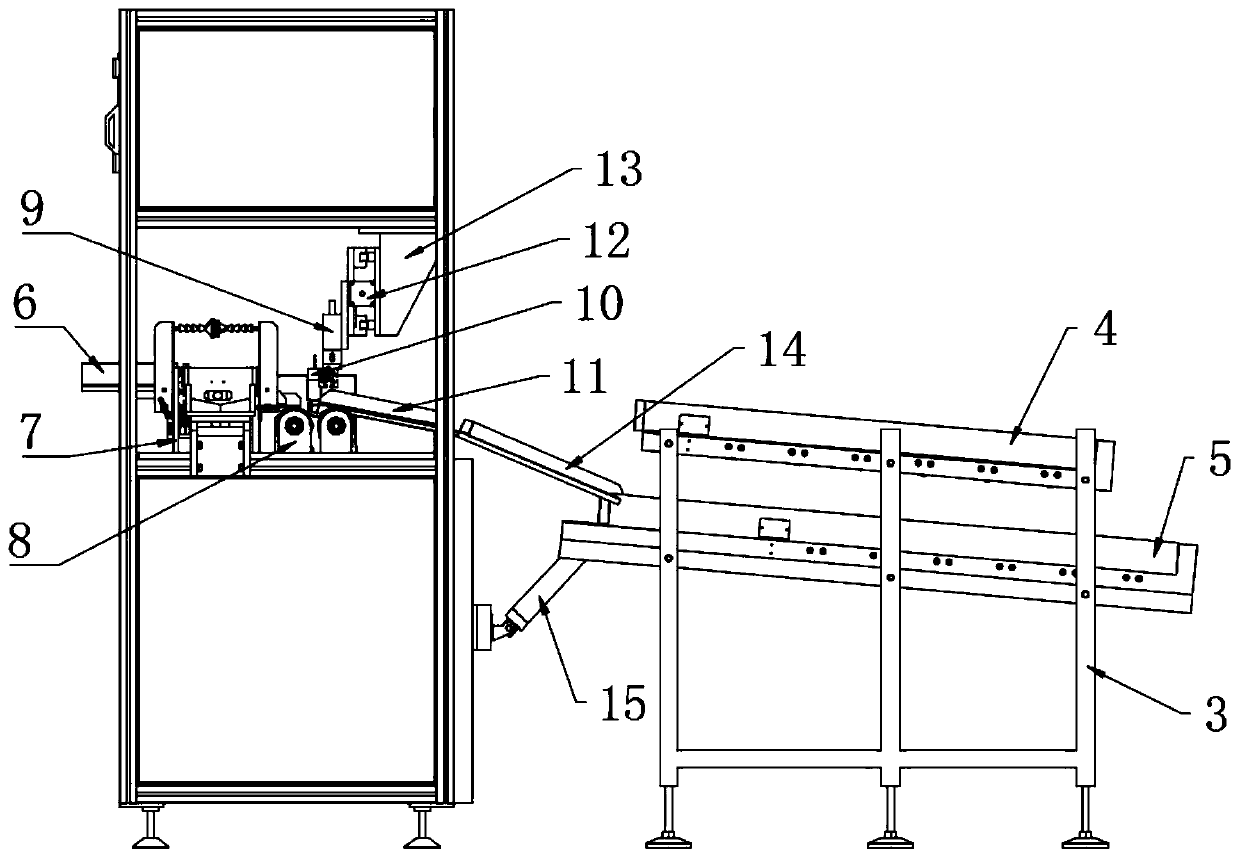

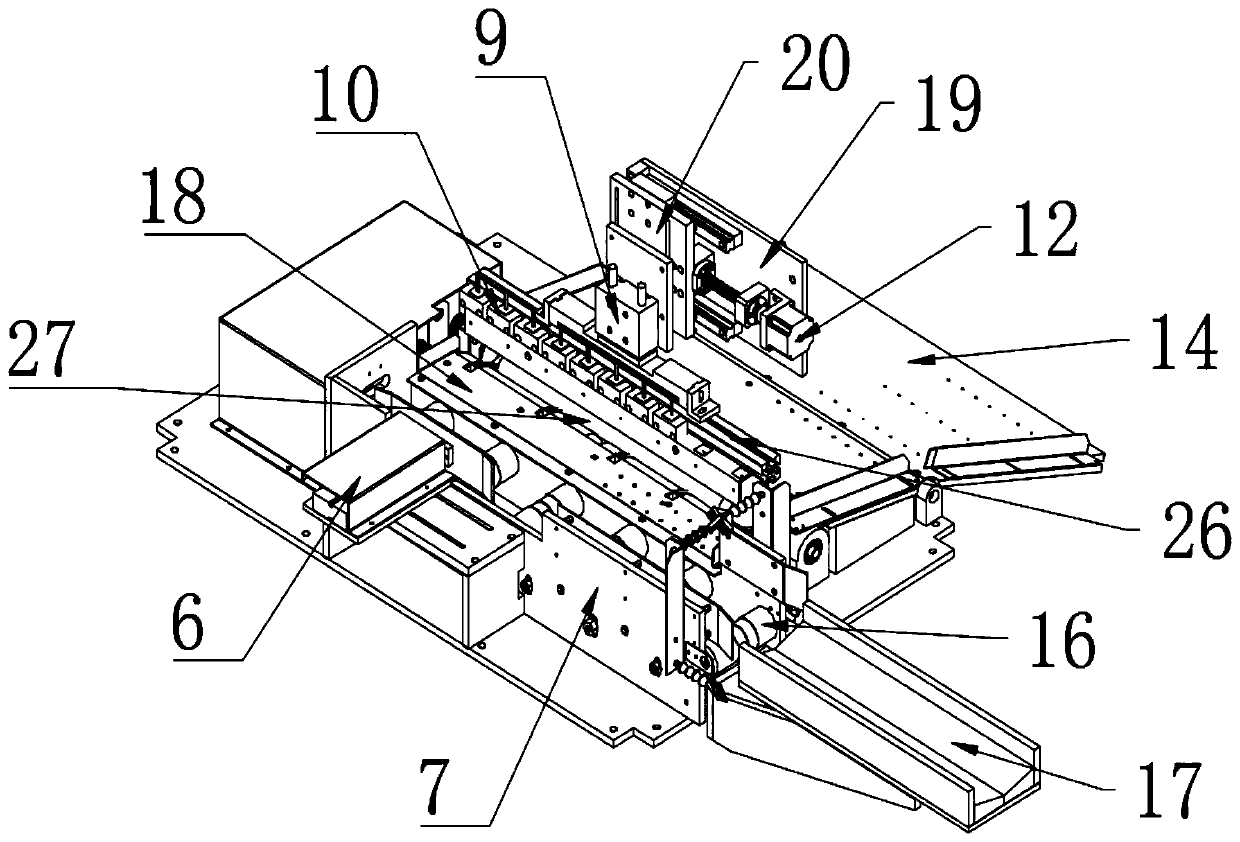

[0027] Such as Figure 1-4 As shown, according to an embodiment of the piston rod eddy current flaw detector provided by the present invention, it includes a workbench 1, and a stocker 3 is arranged on one side of the workbench 1, and the top of the workbench 1 close to the stocker 3 The direction is provided with a feeding mechanism, a detection mechanism, and a material distribution mechanism in sequence. The storage rack 3 is arranged close to the material distribution mechanism. The assembly includes two rotating driving rollers, the unloading turning mechanism is located between the two rotating driving rollers, the feeding mechanism is connected to the workpiece rotating assembly through the first material guide plate 18, and the workpiece rotating assembly passes through the first The second materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com