Viscous material batching and adding method

A material and viscous technology, which is applied in the field of viscous material mixing, can solve the problems of increasing cost and processing time, increasing mixing equipment, difficult continuous production, etc., to solve the problem of continuous and stable adding, low transformation cost, continuous and stable adding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below with reference to the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

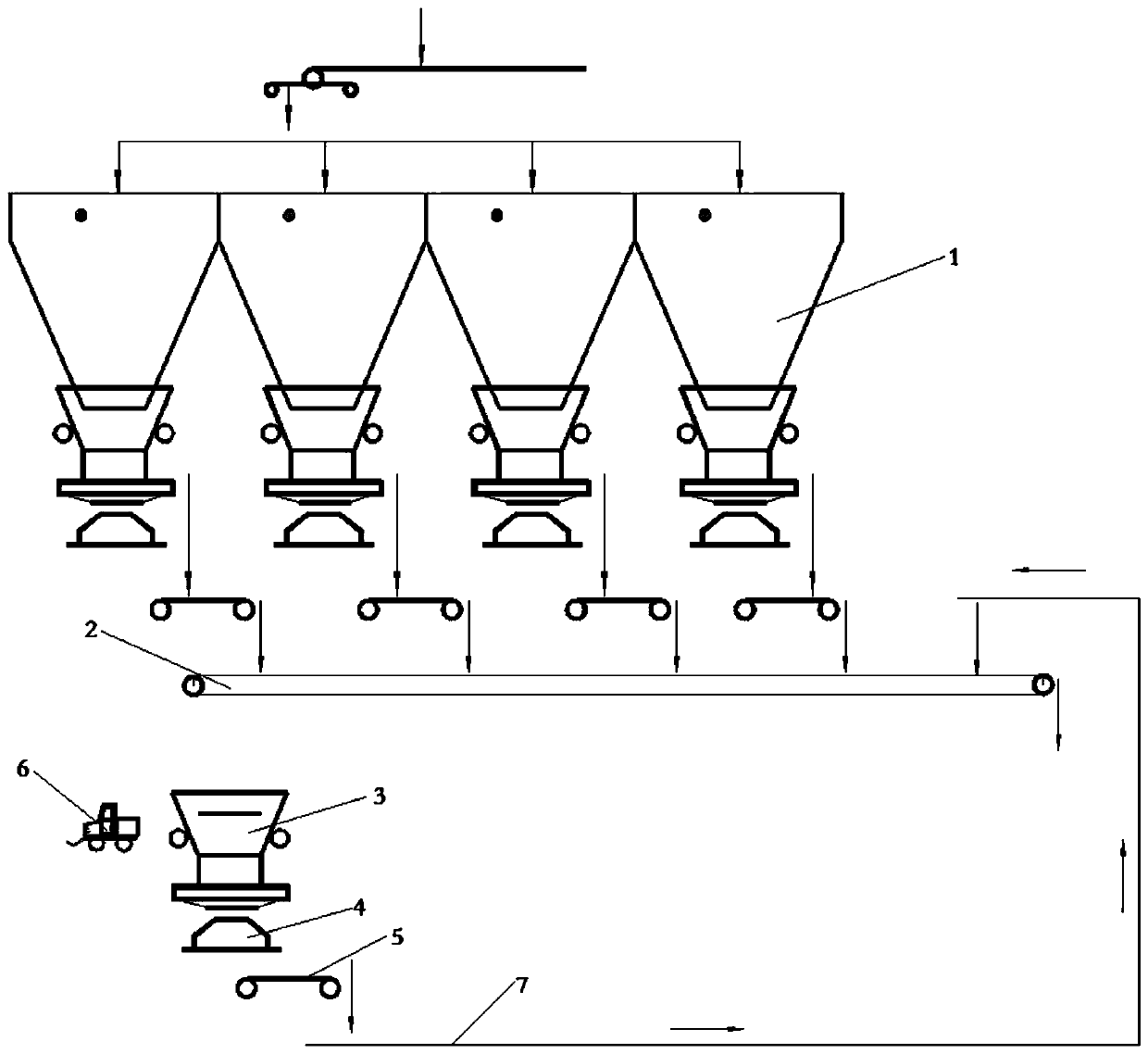

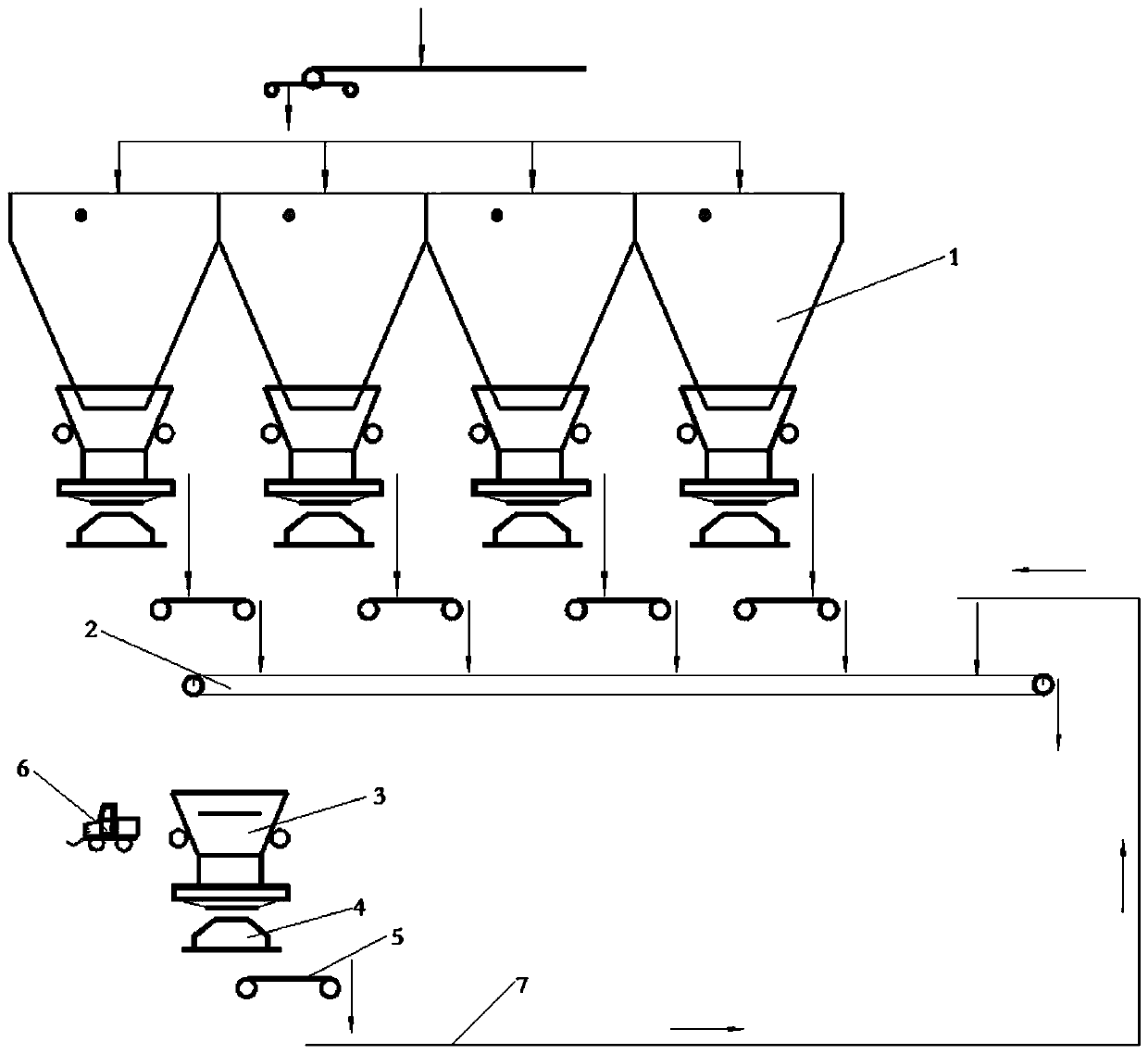

[0019] A viscous material mixing and adding method, the ordinary material is batched through the ordinary material trough and transported to the belt of the batching belt conveyor, the material taking machine is an excavator, and the viscous material is taken and placed into the viscous material trough by the excavator for batching And transported to the belt of the viscous material belt conveyor, the viscous material belt conveyor will transport the prepared viscous material to the batching belt to mix with the prepared ordinary materials, and then send it into the mine tank through the lower hopper of the batching belt conveyor to complete the batching. After the batching is completed, it is transported to the pile for mixing or directly mixed for use.

[0020] The numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com