Raw vegetable processing boiling device for fast food restaurant

A technology for fast food restaurants and lettuce, which is applied to heating devices, the structure of cooking utensils, cooking utensils, etc., can solve the problems of untimely serving of food by fast food restaurant personnel and many people in fast food restaurants, and achieves fast heat preservation and fast hot material. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

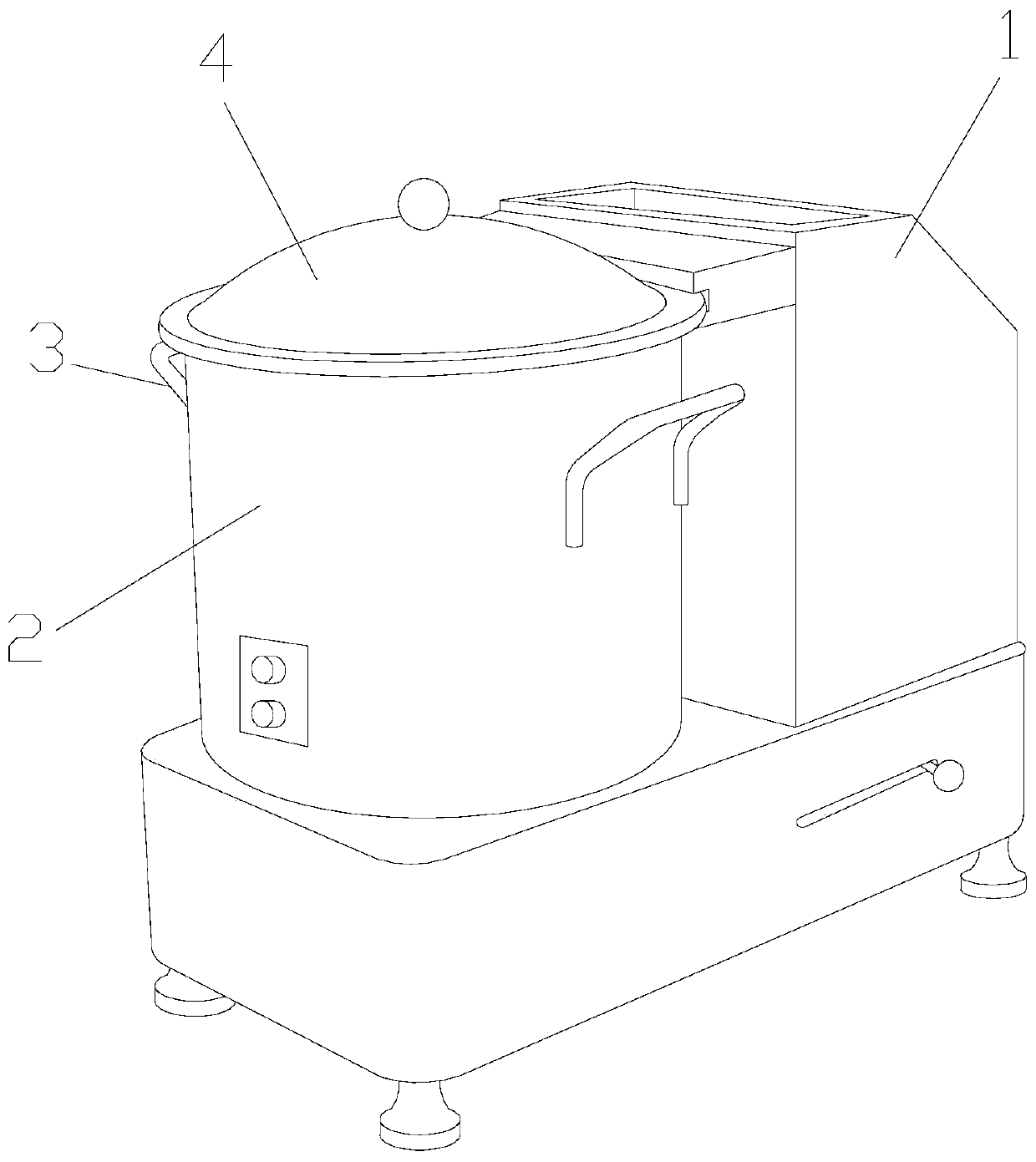

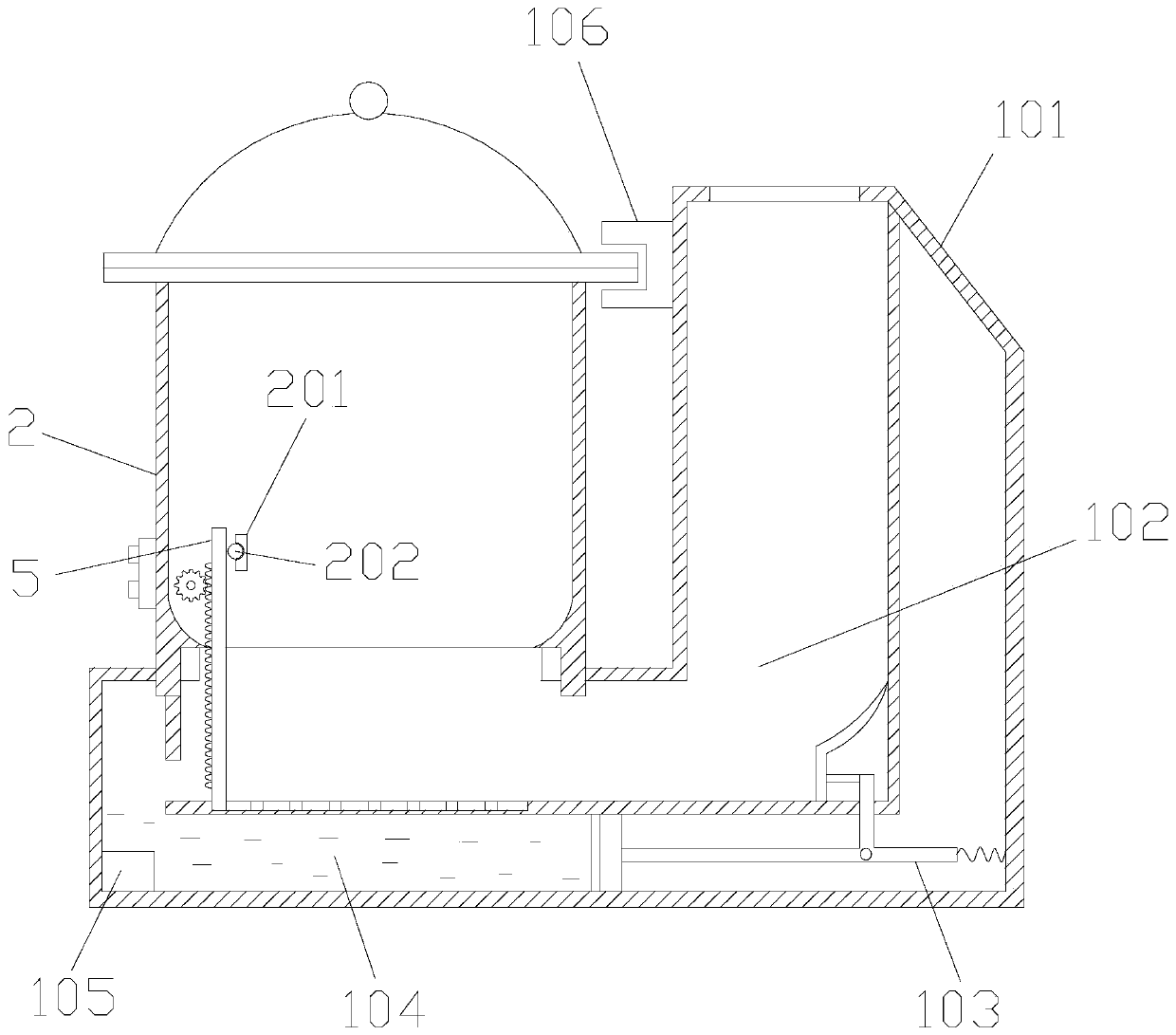

[0028] see Figure 1-Figure 7 , the present invention provides a lettuce processing scalding device in a fast food restaurant. On the surface of the ironing device 1, a pot cover 4 is provided on the top of the material holding pot 2, and the material holding pot 2 and the pot cover 4 are movably connected, and two handles are arranged on the surface of the material holding pot 2 3. The material holding pot 2 and the handle 3 are welded by electric welding, and a feeding mechanism 5 is installed on the inner wall of the material holding pot 2;

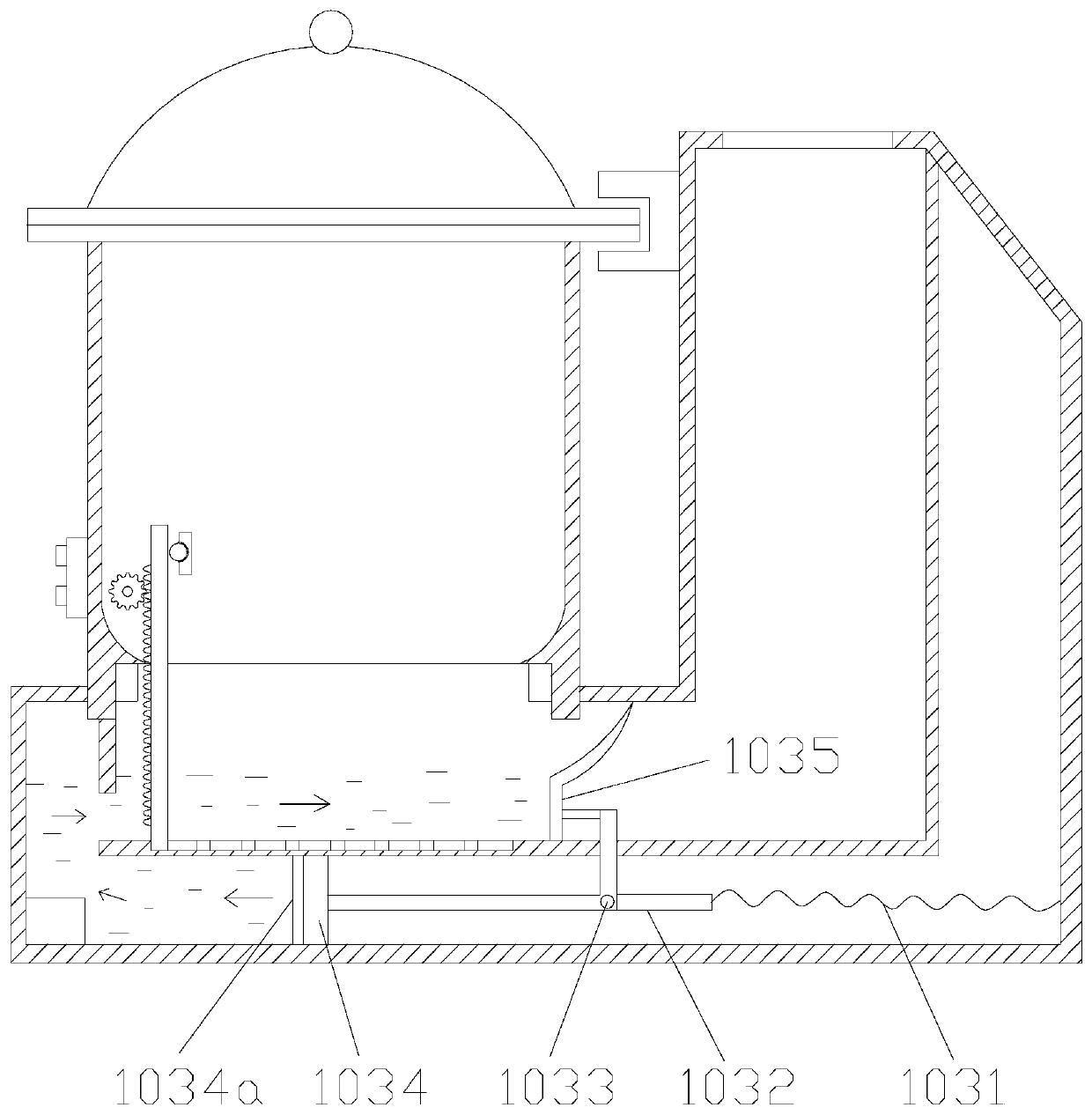

[0029] The ironing device 1 is composed of a machine body 101, a ironing chamber 102, a water guiding mechanism 103, a heating chamber 104, a heater 105, and a cover clamp 106. The ironing chamber 102 is provided inside the body 101, and the The heating chamber 104 is located at the inner bottom of the body 101, the inner bottom of the body 101 is equipped with a water guiding mechanism 103, the surface of the body 101 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com