Non-contact air-heating-type electronic cigarette heater

A non-contact heating and air-type technology, applied in tobacco, smoker’s supplies, applications, etc., can solve the problems of small smoke volume, peculiar smell of products, waste of tobacco, etc., and achieve the effect of increasing smoke volume and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

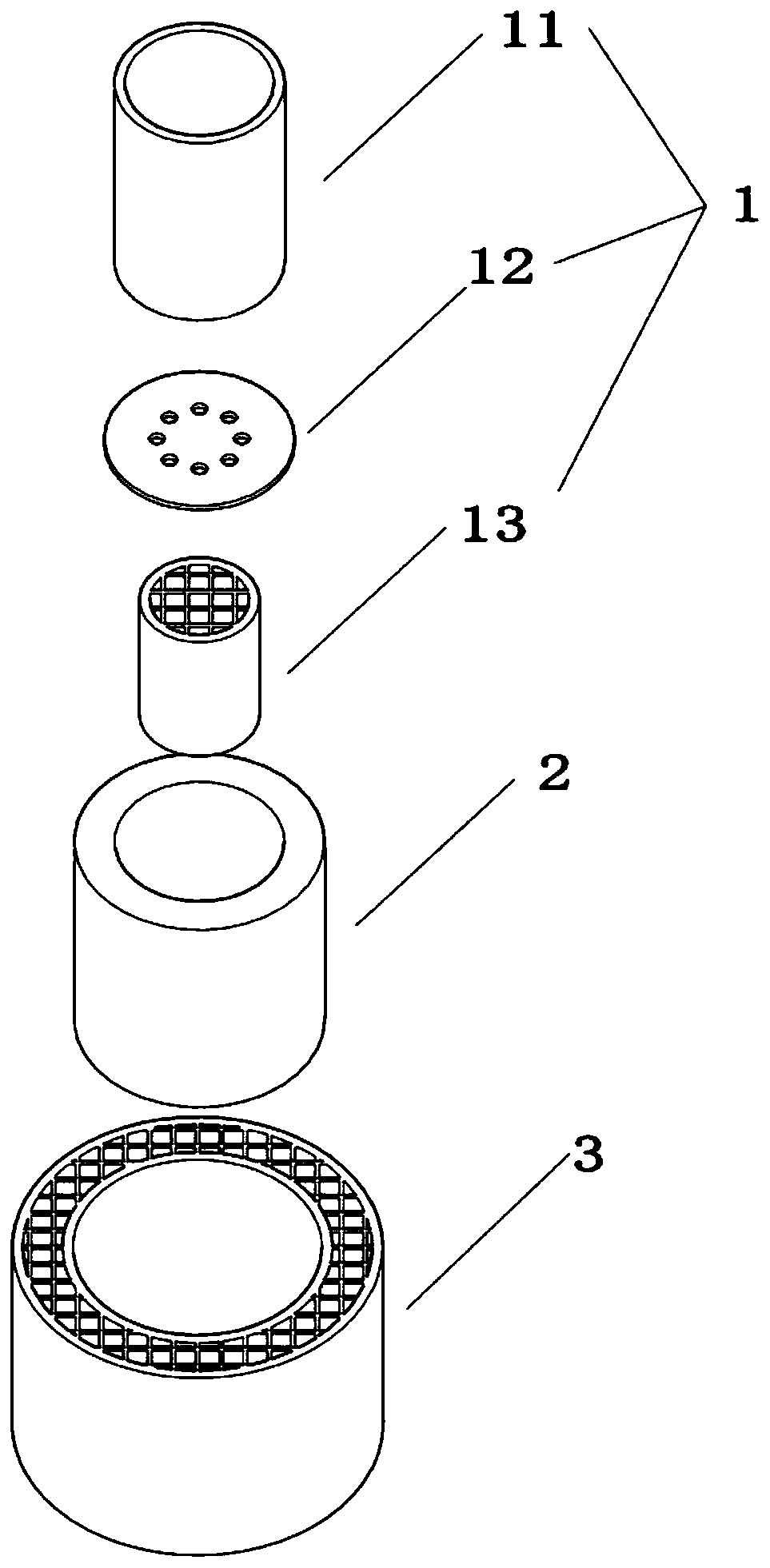

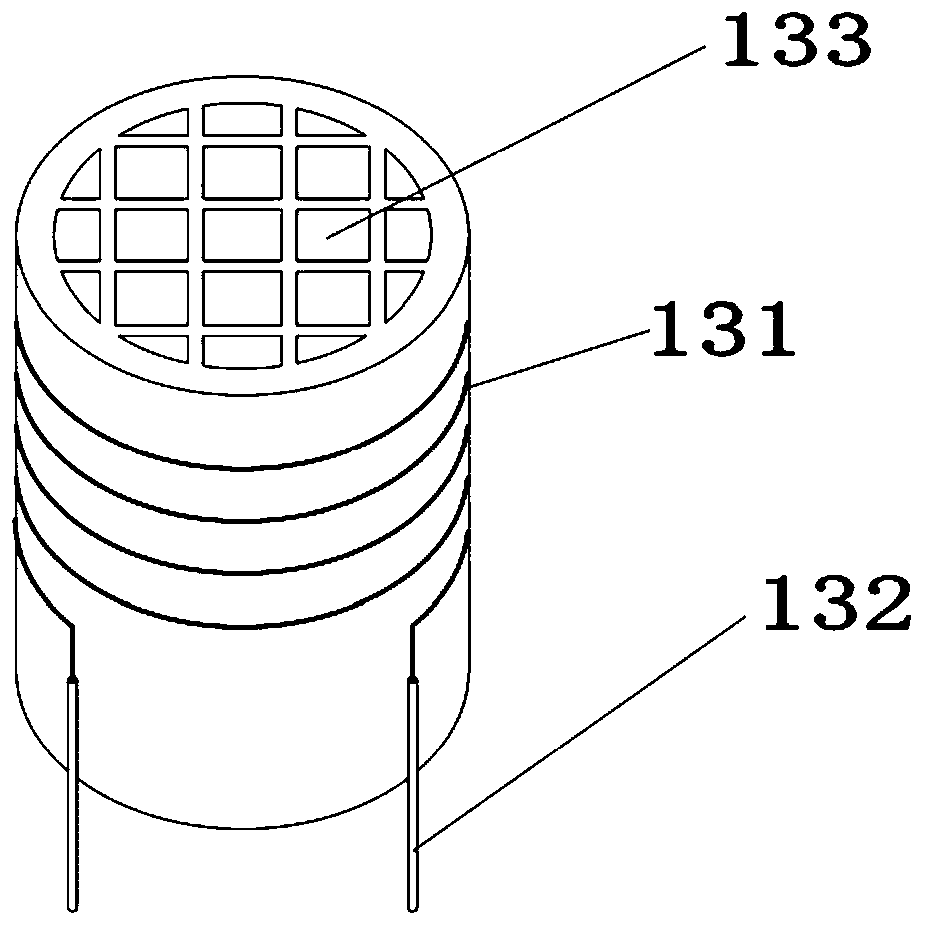

[0022] A non-contact heating air electronic cigarette heater, including a heating assembly 1, a sealing sleeve 2 and a heat recovery device 3, characterized in that a first honeycomb porous channel is provided in the side wall of the heat recovery device 3 31, the first honeycomb porous channel 31 divides the heat recovery device 3 into an outer wall 32 and an inner wall 33; the inner wall 33 of the heat recovery device 3 is provided with a sealing sleeve 2, and the sealing sleeve 2 is covered with a heating assembly 1, The heating assembly 1 is connected to the heat recovery device 3 through the sealing sleeve 2; a heating element 13 is arranged inside the heating assembly 1; a heating circuit 131 is arranged on the heating element 13, and a heating circuit 131 is arranged at an end There are wires 132, and a second honeycomb porous channel 133 is arranged in the heating element 13.

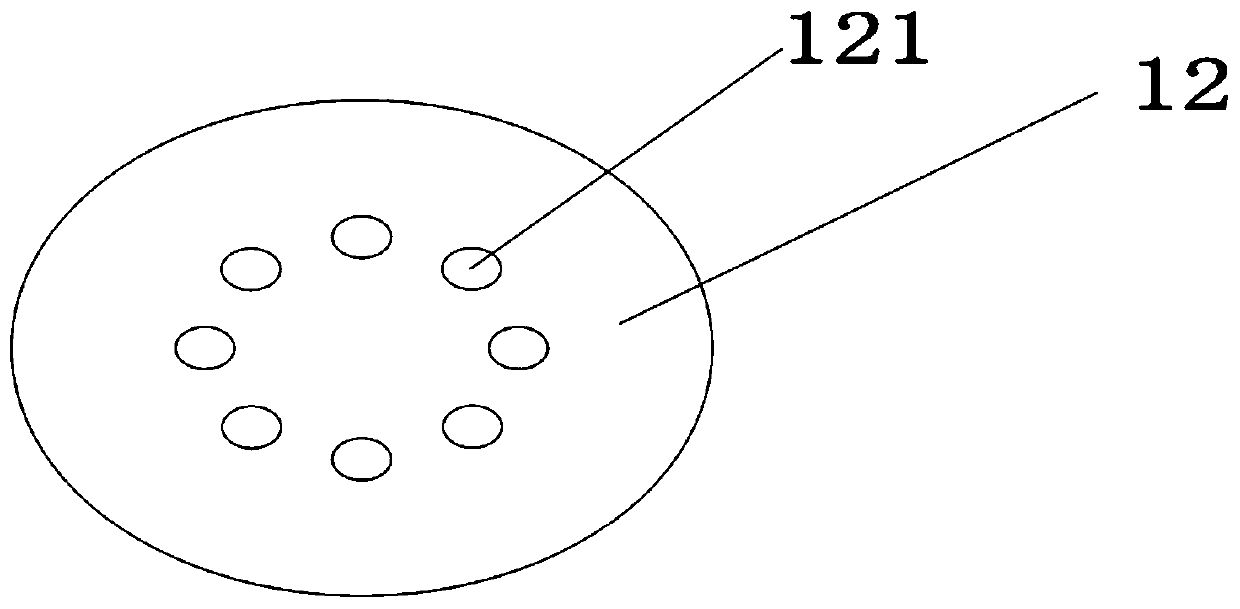

[0023] Further, the heating assembly 1 includes a preheating pipe 11 , a flow guide plate 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com