Cigarette support for heating non-burning cigarettes

A heat-not-burn, cigarette-sticking technology, applied in tobacco, application, and cigar manufacturing, etc., can solve problems such as large smoke adsorption, smoke retention, and cooling section collapse, so as to achieve large smoke-carrying dose and improve support Performance, effect of increasing throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way. Any transformation or replacement based on the teaching of the present invention belongs to the protection scope of the present invention.

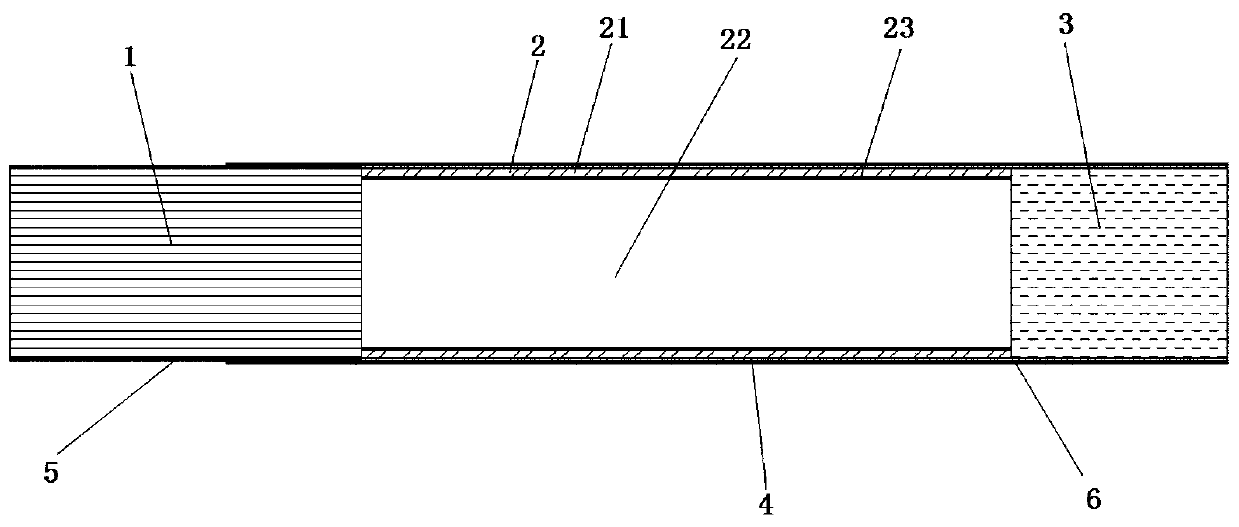

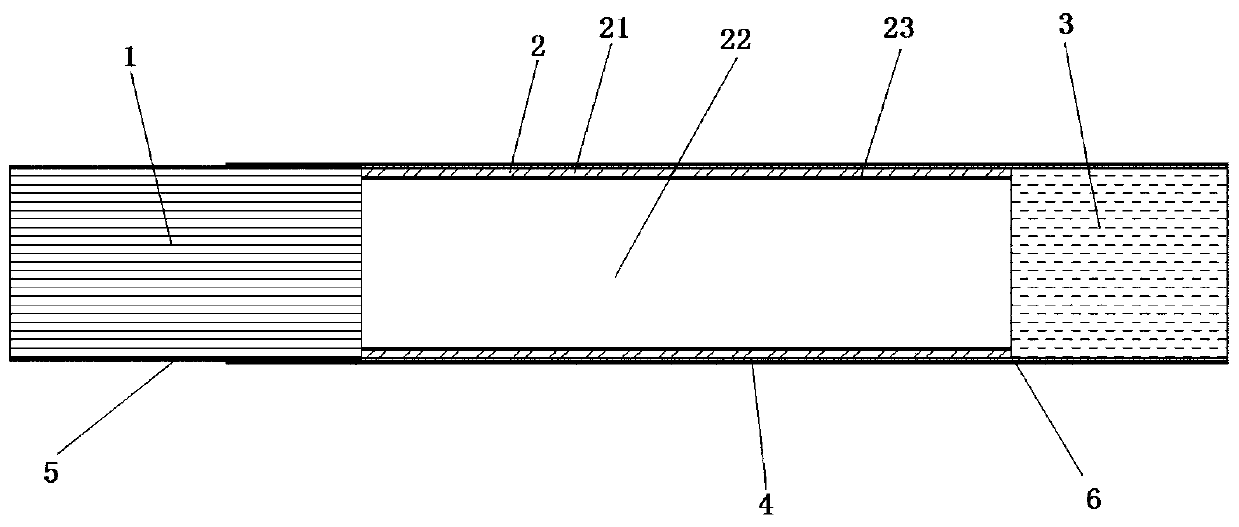

[0023] This embodiment is a cigarette for heat-not-burn cigarettes, which sequentially includes: a cigarette core section 1, a cooling section 2 and a filter section 3;

[0024] The cooling section 2 is an empty tube having a tube wall 21 and a lumen 22, and the inner wall of the tube wall 21 is a polymer material non-woven fabric layer 23;

[0025] The cooling section 2 and the filter section 3 are wrapped by molding paper 4 to form a binary composite tip, the cigarette core section 1 is wrapped by cigarette paper 5 to form a tobacco section, and the binary composite tip and the tobacco section are passed through Tipping paper 6 tipping.

[0026] The outer wall of the tube wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com