Overturning and lifting integrated driving tea machine

A technology of driving and driving adjustment mechanisms, which is applied in the directions of conveyors, liquid handling, transportation and packaging, etc. It can solve the problems of hindering the rotation and discharging of tanks, and achieve the effects of easy implementation, stable power transmission and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

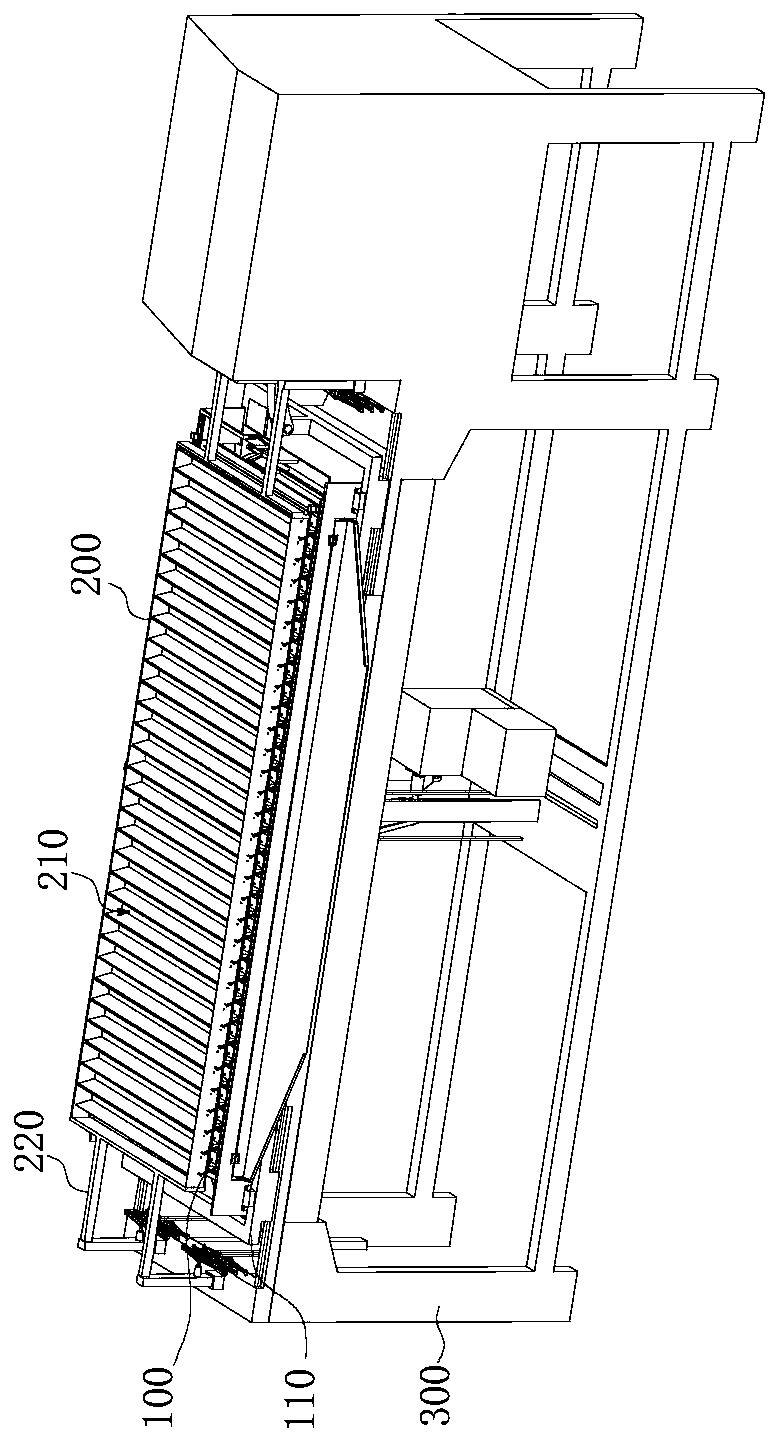

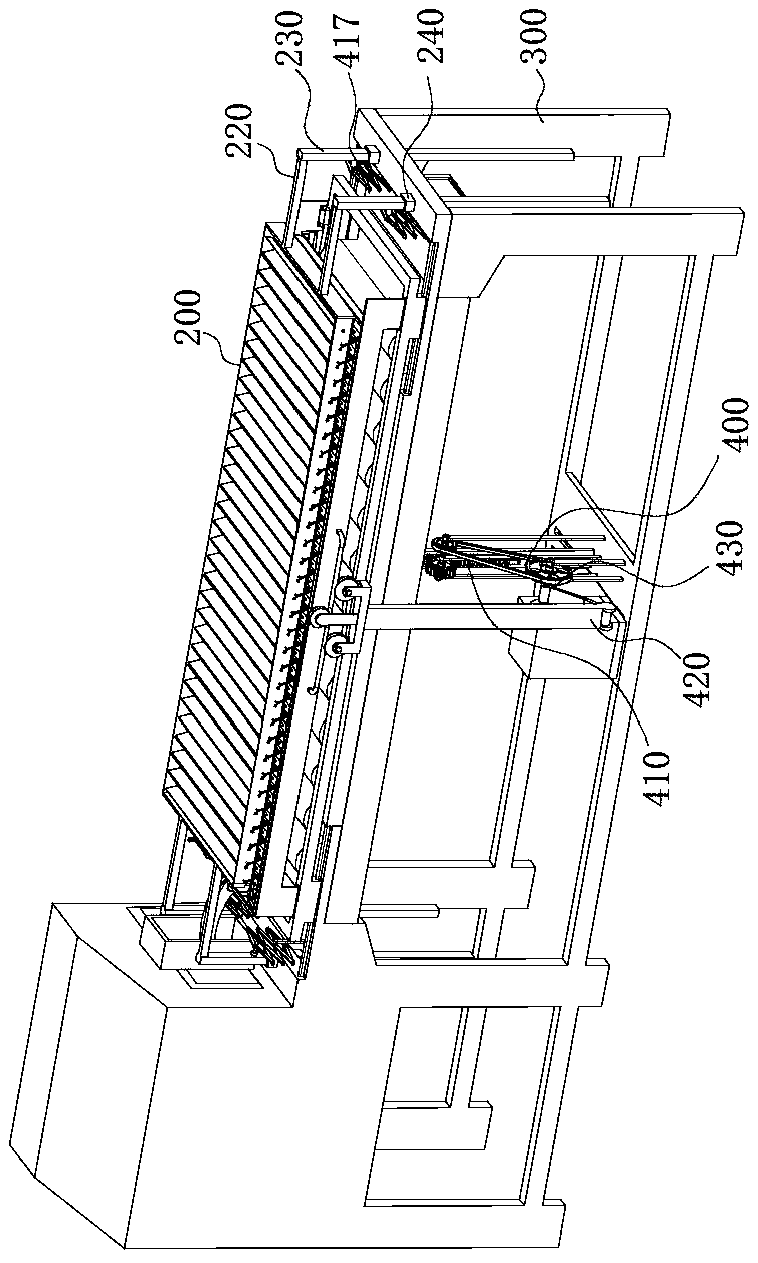

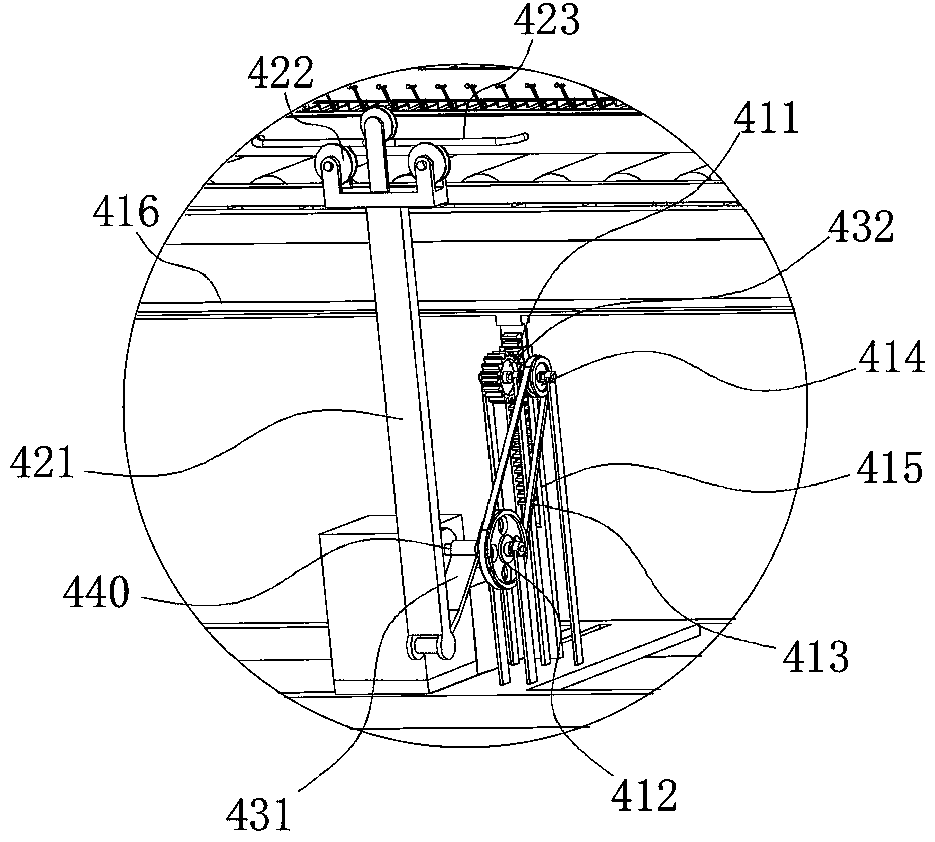

[0041] refer to Figure 1-5 , in the embodiment of the present invention, a turning and lifting integrated drive tea machine is proposed, including a pot 100, a distributing device 200 and a drive adjustment mechanism 400, the distributing device 200 is arranged above the pot 100, and the distributing device 200 is used to For distributing material in the tank 100, the drive adjustment mechanism 400 is used to drive the tank 100 to rotate and discharge the material, and adjust the material distribution device 200 so that the material distribution device 200 can avoid the tank 100 when rotating and discharging.

[0042] Because the distributing device 200 needs to carry out distributing in the pot 100, so the distributing device 200 is arranged on the top of the pot 100, but when the pot 100 rotates and pours, the distributing device 200 at the top will hinder the rotation of the pot, so that Therefore, the present invention can not only drive the tank pot to rotate and dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com