Spectral adaptive coating material capable of achieving solar heat collection in daytime and radiation refrigeration in nighttime

A technology of solar heat collection and coating materials, applied in the direction of solar thermal power generation, coating, etc., can solve the problems of low thermal efficiency, large radiation heat loss, etc., and achieve the effect of reducing radiation heat loss and reducing the complexity of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

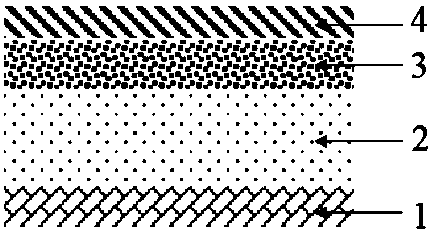

[0040] see figure 2 , a spectrally adaptive coating material for solar heat collection during the day and radiative cooling at night includes a base layer 1 , an infrared emitting layer 2 , a phase change layer 3 and an anti-reflection layer 4 arranged in sequence from bottom to top.

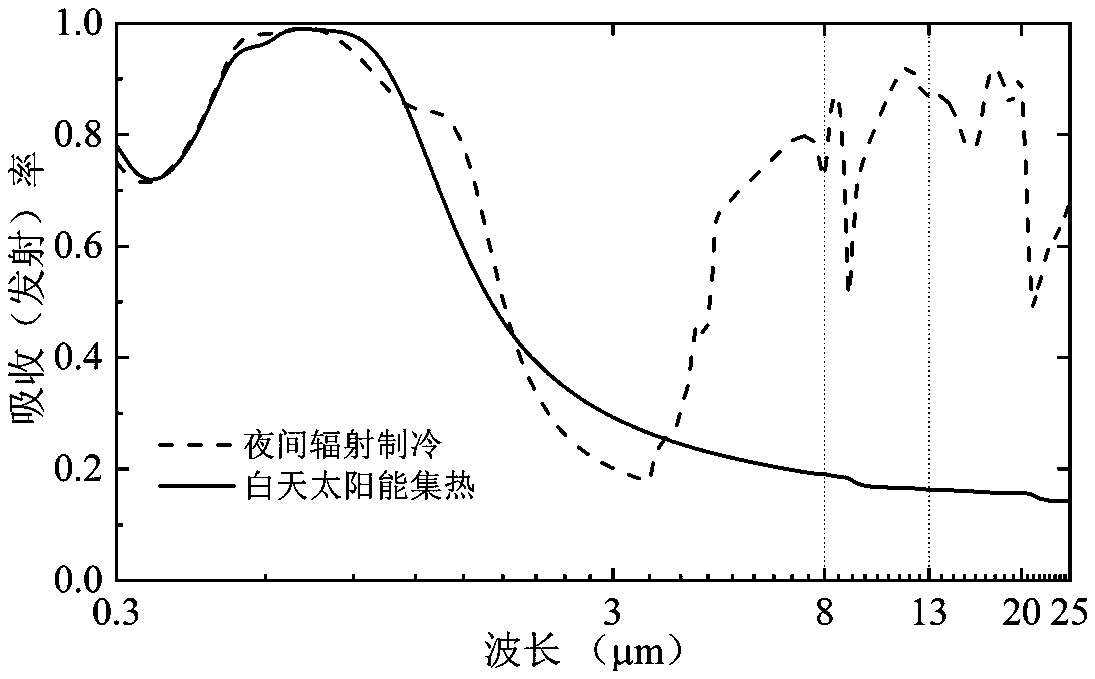

[0041] The base layer 1 is aluminum with a thickness of 150 nm; the infrared emission layer 2 is quartz with a thickness of 500 μm; the phase change layer 3 is vanadium dioxide with a thickness of 200 nm; the anti-reflection layer 4 is aluminum oxide with a thickness of 86 nm. Its spectral emission (absorption) rate in the 0.3-25 μm band in the heat collection mode during the day and the radiative cooling mode at night is as follows: image 3 shown.

[0042] During the day, when the temperature of the coating material is higher than the transition temperature, the absorptivity of the coating material in the solar radiation band (0.3-3 μm) is 0.85, and the emissivity in the infrared band (3-25 ...

Embodiment 2

[0044] see figure 2 , a spectrally adaptive coating material for solar heat collection during the day and radiative cooling at night includes a base layer 1 , an infrared emitting layer 2 , a phase change layer 3 and an anti-reflection layer 4 arranged in sequence from bottom to top.

[0045] The base layer 1 is 200 nm thick tungsten; the infrared emission layer 2 is 500 μm thick aluminum oxide single crystal (also known as sapphire); the phase change layer 3 is 230 nm thick vanadium dioxide; the antireflection layer 4 is made of 176 nm thick Silicon dioxide (low refractive index material), 44 nm thick vanadium dioxide (high refractive index material) and 92 nm thick silicon dioxide (low refractive index material) are sequentially overlapped. Its spectral emission (absorption) rate in the 0.3-25 μm band in the heat collection mode during the day and the radiative cooling mode at night is as follows: Figure 4 shown.

[0046] During the day, when the temperature of the coati...

Embodiment 3

[0048] see figure 2 , a spectrally adaptive coating material for solar heat collection during the day and radiative cooling at night includes a base layer 1 , an infrared emitting layer 2 , a phase change layer 3 and an anti-reflection layer 4 arranged in sequence from bottom to top.

[0049] The base layer 1 is black chrome selective absorption coating; the infrared emission layer 2 is glass with a thickness of 1 mm; the phase change layer 3 is vanadium dioxide with a thickness of 160 nm; the anti-reflection layer 4 is aluminum oxide with a thickness of 50 nm. Its spectral emission (absorption) rate in the 0.3-25 μm band in the heat collection mode during the day and the radiative cooling mode at night is as follows: Figure 5 shown.

[0050] During the day, when the temperature of the coating material is higher than the transition temperature, the absorptivity of the coating material in the solar radiation band (0.3-3 μm) is 0.85, and the emissivity in the infrared band (3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com